Direct reduced iron (DRI) is produced by reacting iron ore with H2-rich syngas, fueled by natural gas, in over 150 facilities worldwide. Direct reduced iron costs $300/ton, consuming 3,000kWh/ton of energy and 0.6 tons/ton of CO2. The process can be decarbonized via low-carbon hydrogen, as the world strives towards decarbonized steel.

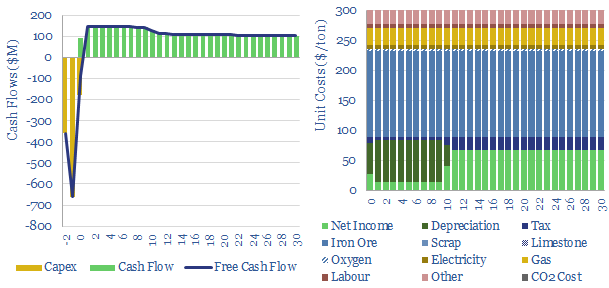

This data-file is an economic model of direct reduced iron (DRI) costs, including a breakdown of capex, opex, natural gas, electricity, iron ore, other materials, labor and taxes.

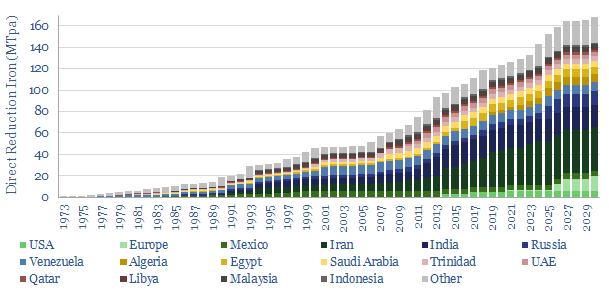

Direct reduced iron underpins 6% of global steel production, running to 120MTpa of the world 2GTpa global steel production and ramping up steadily since the 1970s (chart below).

How does the direct reduction iron process work? Iron ore is heated in a shaft furnace, alongside syngas, which contains CO and H2 derived from natural gas, thereby reducing the iron oxide, while forming waste gases of H2O and CO2. The product can later be upgraded into steel in an electric arc furnace.

Leading DRI technologies include Midrex and Tenova HYL, and the data-file contains a database of all the deployments to-date, plus future low-carbon plans.

DRI products include Hot DRI (converted straight into an EAF before it is cooled down), Cold DRI that is cooled down to below 60C before subsequent processing, and ‘Hot Briquetted Iron’ (HBI), which is a stabilized product and can be shipped globally in a bulk tanker.

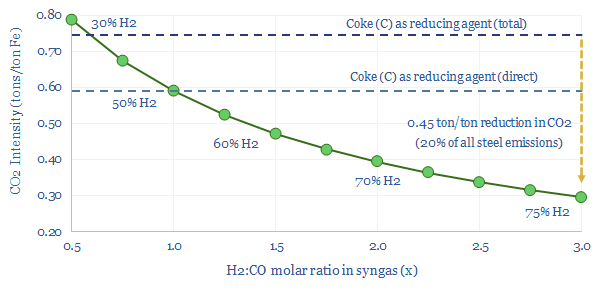

Base case costs for producing DRI most likely run to $300/ton of iron, to earn a 10% IRR on a 2MTpa production facility costing $600M. Energy intensity is most likely around 3,000 kWh/ton and CO2 intensity is modelled at 0.6 tons/ton of iron, although this will vary according to the percent of iron reduction delivered by hydrogen versus CO (chart below).

CO2 intensity for the overall value chain is currently estimated at around 1.1 tons/ton, which is 50% lower than the blast furnace/basic oxygen furnace route.

For decarbonization of the steel industry, we think that direct reduced iron can increasingly be made with hydrogen comprising almost all of the reducing agent, and renewables-heavy electricity. Ultimately, this can reduce the total CO2 intensity to 0.6 tons/ton, which is 75% below higher-CO2 steel.