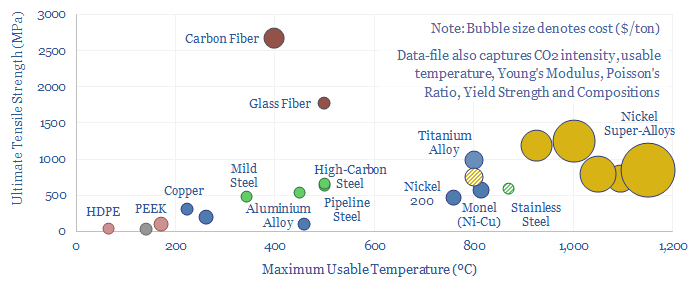

This data-file aggregates information into the strength, temperature resistance, rigidity, costs and CO2 intensities of important structural metals and materials. It shows why nickel-based super-alloys are used in gas turbines and jet engines; why glass fiber and carbon fiber are used in wind turbine blades; why traces of Rare Earth metals are introduced into high-pressure pipelines for gas transportation or CCS; why overhead power lines are blends of aluminium and steel.

Strength is the ability to withstand forces? 1 Pascal means that a force of 1 Newton is acting over an area of 1 m2. When applied to gases, 1 Pascal of force per m2 of area denotes pressure. But when applied to solid materials, 1 Pascal of force per m2 of area denotes stress.

Stress and strain. As more stress is applied to materials, they begin to deform. For example, under ‘tensile stress’, where the force is pulling a material apart, the strain may occur as elongation.

Elastic Deformation. The type of strain caused by low levels of tensile stress is ‘elastic deformation’, which means that the material will revert to its original shape when the stress is removed.

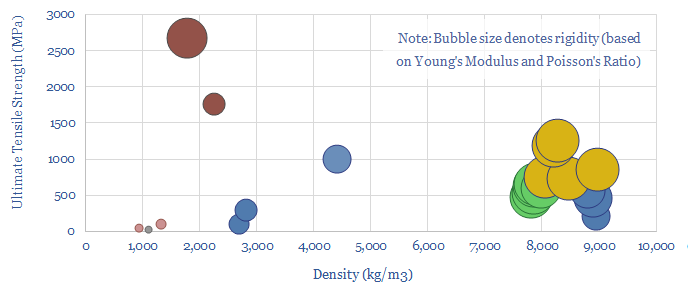

Young’s Modulus. During elastic deformation, there will be a fixed ratio of stress-to-strain. Each additional unit of stress (in GPa) causes a fixed degree of elongation (dimensionless). High Young’s Modulus means a more rigid and less elastic material.

Yield Strength. Beyond a certain degree of stress, additional stress will not cause further elastic deformation, but instead, will cause plastic deformation. When this stress is removed, then the material does not return to its original shape. Yield strength is measured in MPa.

Ultimate Tensile Strength. If stress increases further, then ultimately the material will fail. It will ‘neck open’ and then tear. The point at which this begins to happen is the Ultimate Tensile Strength. And it is also measured in MPa. In other words, a tensile strength of 500 MPa means that it will take a mass of 50kT tons to tear apart 1m2 of a material.

Poisson’s Ratio. Also during elastic deformation, as a material stretches, it will become narrower. A very stretchy material, such as rubber, has a Poisson’s Ratio close to 0.5. Conversely, a material such as paper has a very low Poisson’s Ratio, around 0.1, and will ‘give’ very little before tearing.

Other Metrics. There are other types of stress, such as compressive, shear and rotational stress. We are not going to catalogue all of these properties in this file, but use tensile stress as a proxy.

This data-file aggregates information into the strength, temperature resistance, rigidity, costs and CO2 intensities of important structural metals and materials, which matter increasingly in the energy transition.

The data show why nickel-based super-alloys are used in gas turbines and jet engines, due to their resistance to deformation, even at high temperatures. The efficiency of a gas turbine/jet engine is a direct function of the hottest temperature in the Brayton Cycle.

In the wind industry, glass fiber and carbon fiber are used in wind turbine blades, as they are exceptionally light and rigid.

In CCS and gas transportation, traces of Rare Earth metals such as Niobium are introduced into high-pressure pipelines, to impart higher strength, and enable higher volumes of flow, even of mildly corrosive fluids, without requiring overly thick pipeline walls.

In power grids, overhead power lines are not made from conductive copper, but blends of aluminium and steel, for structural reasons.