Amprius is commercializing a lithium-ion battery with a near-100% silicon anode, which has 80% higher energy density than conventional lithium and can achieve 80% charge rates within around 6-minutes. The company is listed on NYSE. We have reviewed Amprius’ silicon anode technology. The patent library is excellent, goes back to 2009 and has locked upon a specific design. This allows us to guess at costs, degradation and longevity.

Silicon has an anode capacity of 3,400 mAh/gram, which is 10x higher than a graphite anode at 355 mAh/gram. Hence using a silicon anode in a lithium-ion battery confers higher energy density and faster charging (as the lithium ions have ‘less far to travel’). What has hindered silicon anode batteries in the past is swelling 3-4x when lithium ions intercalate. This can cause battery degradation, reviewed in detail in our note here.

Amprius states that its technology uses a 99.5-99.9% pure silicon nanowire, which can accommodate 300-400% volume expansion without degrading. The battery has been tested, validated by partners and is being deployed. By early-2023, 10,000+ batteries have been shipped, extending across 10 SKUs; and GWh-scale manufacturing started in 2021.

The majority of Amprius’ patents that we reviewed were focused on overcoming degradation challenges resulting from graphite anodes expanding by 4x when lithium ions intercalate, which typically causes stresses and crumbling of the anode.

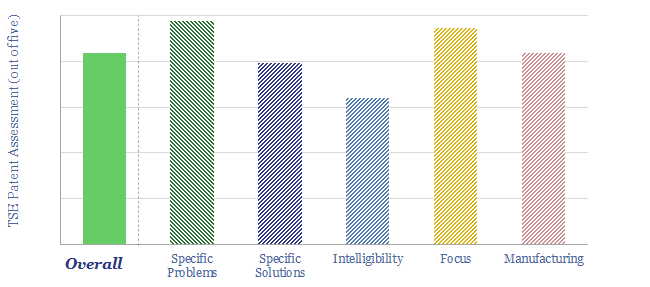

The patent library goes back to 2009. Earlier patents are quite broad ranging. But later patents have quite clearly locked in upon a specific design (some of the images in these patents directly match up to the images in Amprius’ latest investor presentations).

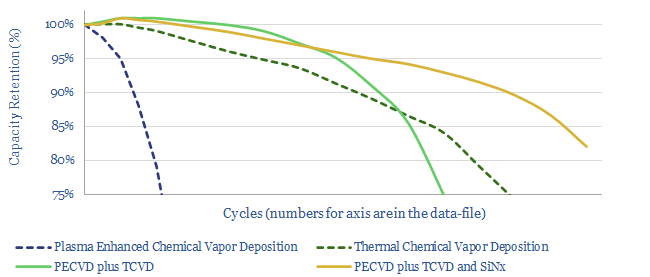

Helpfully, these patents also explain how the silicon anode is to be manufactured (we think there are three separate vapor deposition stages: forming nano-wires above oxidized nucleation points on a substrate; coating the nano-wires with a first silicon layer; then coating the nano-wires with a second, differently shaped silicon layer).

Manufacturing costs of Amprius’ silicon anode batteries can be guessed, approximately in $/kWh terms, using some rules of thumb over the costs of these manufacturing processes compared to battery-grade graphite, and then flowing the higher anode costs through to our build-up of battery costs.

Longevity of Amprius’ silicon anode batteries can also be estimated from technical data that are presented in the patents. We think lifespan is good enough to de-risk large-scale deployment of the technology in specific applications. However, we think the longevity of well managed lithium-ion batteries can still be at least 10x higher.

Further details on Amprius’ silicon anode technology are covered in the data-file. We have also reviewed an interesting silicon anode battery technology from Enovix. Our top conclusions into batteries and energy storage are summarized here.