An overview of manufacturing methods is given in this data-file, covering different means of upgrading, separating, heat-treating, drying, depositing, shaping and assembling different manufactured products.

In each case, we have aimed to quantify the relative costs, energy intensity, typical throughput volumes, an explanation of the process, and examples for how it is used.

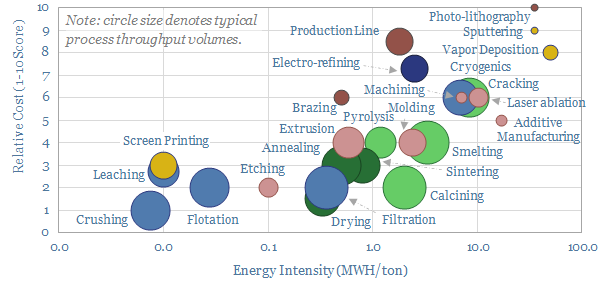

Energy intensity varies vastly, and is 70% correlated with costs of the processes. But as a rule of thumb, a manufacturing process with <0.3 MWH/ton energy use is energy-light, while a process with >7MWH/ton energy use is energy-intensive.

Some of the lowest-cost methods are associated with the mining industry, where they are deployed at enormous scale (multi-MTpa), such as crushing, flotation and leaching; while screen-printing is one of the lowest cost assembly processes.

Conversely, some of the highest-cost methods are associated with the semiconductor industry, involving the deposition of very thin and intricately positioned patterned layers on a substrate. These methods include photolithography, sputtering and vapor deposition.

The full data-file gives an overview of different manufacturing methods and is intended as a useful reference file or ‘cheat sheet’, for decision-makers increasingly exploring new solar cells, battery recycling or materials used in the energy transition.

To read our latest commentary on manufacturing methods, please see our article here.