In post-combustion CCS facilities, amines react with CO2, which can later be re-released via steam-treating, and sent for sequestration. However, CCS plants have amine make-up rates, to replace amines that degrade (chemically, thermally) and evaporate off. This data-file quantifies make-up rates of amines in kg/ton.

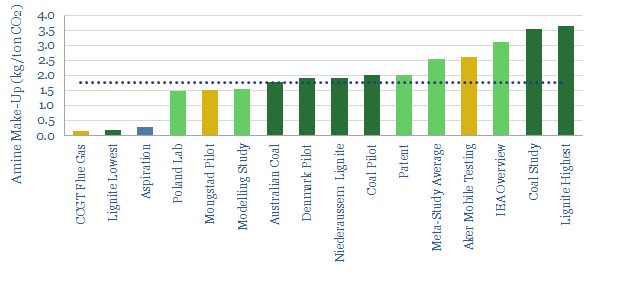

We estimate that amine make-up rates will most likely run at 1.75 kg/ton using MEA, which is the most common amine used in CCS plants. However the ranges are very broad. One widely cited study quotes a range of 0.2-3.7 kg/ton, and another suggests poorly managed plants could have make-up rates as high as 10kg/ton.

This matters as amines comprise $3/ton of our cost build up for post-combustion CCS, using the mid-point estimate of 1.75 kg/ton and a $1,700/ton long-term MEA price. Cash margins are around $11/ton. Hence lower amine use can uplift margins by 10-20%; or conversely, higher amine use can add $3-5/ton, maybe even $10/ton to the cost of CCS.

Amine degradation mechanisms are complex, occurring via oxidative and thermal pathways. Oxidative degradation is accelerated by impurities acting as catalysts, especially metals. Sulphur impurities produce heat stable salts. Evaporative losses correlate with temperature. Operating power plants at partial loads or as peakers can also increase evaporative emissions. Some of the breakdown products, such as nitrosamines are toxic, especially if there are NOXs in the feed gas.

Another question mark is whether some studies are under-estimating amine degradation due to short study times, and as degradation cascades. Primary breakdown products react. Some studies show quite sudden failure after a few thousand hours.

Coal versus gas. It is hard to pinpoint a clear difference in the degradation rates between post-combustion CCS on coal versus gas. On the one hand, coal will have more impurities, but these tend to be cleaned out before CCS, using electrostatic precipitation and wet gas scrubbing. On the other hand, coal plants will burn off more oxygen, so there are lower oxygen concentrations in the flue gas, and less oxidative degradation.