Conveyors are often the most economical way to move bulk materials over long distances, e.g., from a mine to a processing plant, with an economic cost of $0.1/ton-km, in order to generate a 10% IRR on capex, opex and other costs. These costs are c30% lower than for heavy trucks, opex is at least 60% lower, and CO2 intensity is also about 60% lower. Conveyor costs are calculated in this data-file.

Conveyors are used to move bulk materials, via a conveyor belt that loops around a series of driver pulleys and idle pulleys. Sides are often inclined at 20º to the horizontal. Or alternatively, piped conveyors offer a fully enclosed solution, for minimal risk of dust/spillage/products getting wet.

Conveyors are widely used in the mining industry, downstream of a crusher plant, in order to move materials such as coal, iron ore, copper ore, aluminium ore, lithium ore, uranium ore or rare earth ores.

For example, the longest conveyor belt in the world, at Bou Craa in Western Sahara, stretches over 98km from a phosphate mine to the port city of El-Aaiun.

One of the largest conveyors in the world, by power, consumes 58MW, as it moves 100MTpa of copper ore from the base of Chile’s Chuquicamata, the largest open copper pit in the world; lifting it by 1,000 meters of total height, in a system built by TAKRAF and ABB, using 7,500 tons of steel and 35,000 idlers.

There is a trend in the mining industry towards In-Pit Crushing and Conveying (IPCC). Conveyors can tolerate inclines up to 12º and specialized sections up to 35º, whereas haul trucks are limited to gradients of 5º.

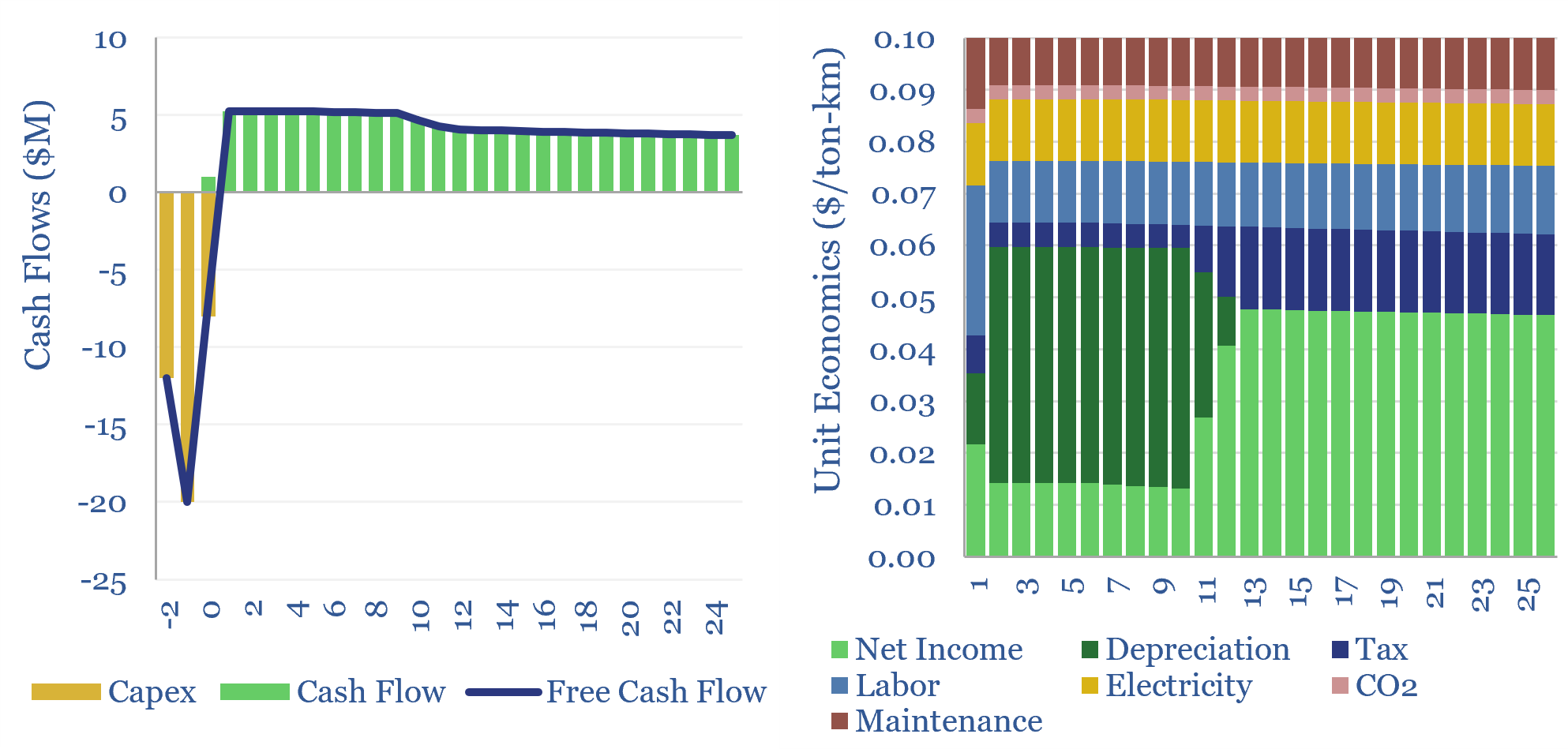

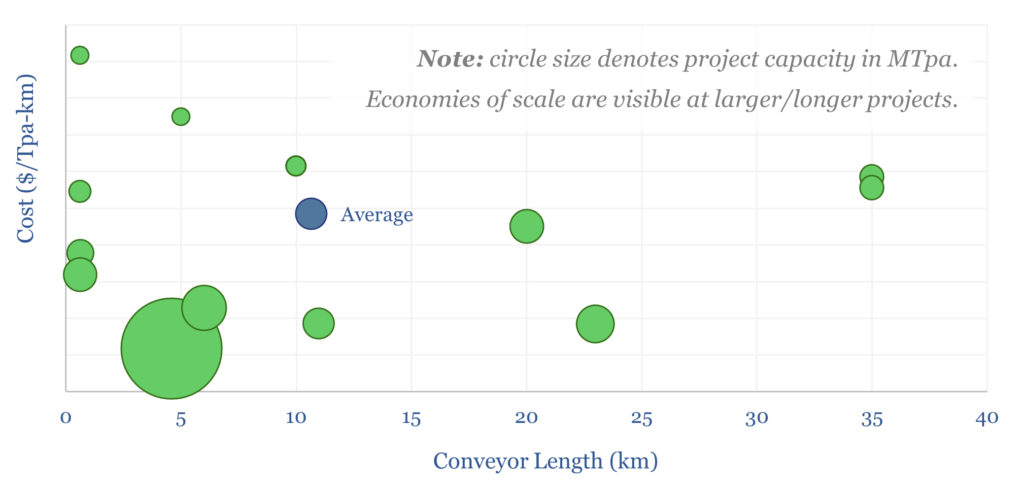

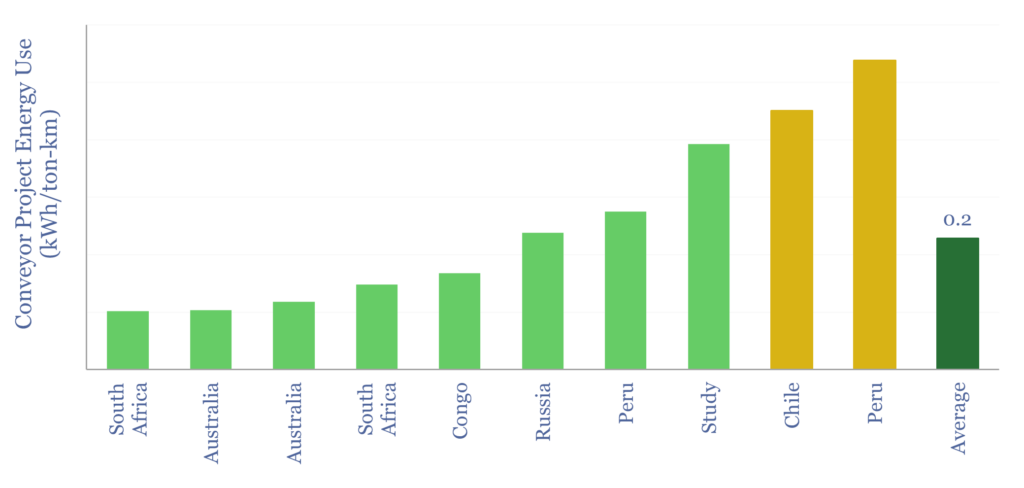

Conveyor costs are built up in this data-file, from first principles, based on the capex costs of past conveyor projects (chart below) and the power consumption needs of past conveyor projects (second chart below).

It is also interesting, in some of these examples, to see who won the order flow, including for efficient motor drivers.

Conveyor costs for moving bulk materials average $0.1/ton-km in our data-file, which is c30% lower than moving material over similar distances via heavy trucks, and even these economics assume pre-existing roads, rather than having to build new roads. Opex is at least 60% lower for conveyors than for heavy trucks. And CO2 intensity is also about 60% lower, or more, as renewables gain share.