What are the costs of hydrogen from coal gasification? This model breaks down the economics, line-by-line, across different plant configurations, backed up with data from half-a-dozen technical papers. We think black hydrogen costs $1-2/kg, but CO2 intensity is very high, as much as 25 tons/ton. It can possibly be decarbonized resulting in semi-clean hydrogen costing c$2.5/kg.

SynGas is a mixture of hydrogen, carbon monoxide and CO2 that is produced by heating coal to around 1,400ºC in an oxygen-limited reactor. The process goes back to 1792, where it was used to produce ‘town gas’. Today, there are over 500 coal gasifiers operating in the world, largely in China and South Africa.

In our base case model, a typical syngas plant must charge around $500/ton, in order to generate a 10% IRR. The syngas can then be used in making chemicals (c50% of the syngas market, e.g., ammonia, methanol), for fuels (c30%), or combusted in a power plant (c20%).

However, CO2 intensity is very high, as much as 0.6 kg/kWh-th, 3x more than natural gas CO2, 1.5x more than average coal grades. Making syngas is only c70-80% efficient at harvesting the energy from coal, which is why the CO2 intensity of syngas is higher than coal itself. Moreover, the product is already partly oxidized (it contains CO), so it releases less energy when it is combusted.

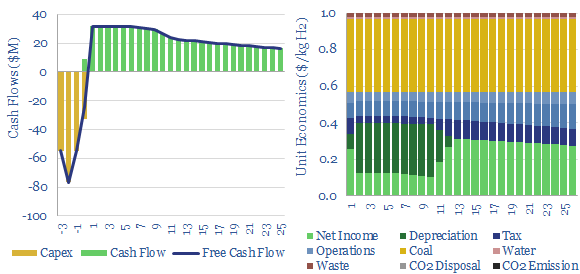

Pure hydrogen can also be separated out from the syngas, by promoting the water-gas-shift reaction, then removing all of the impurities and acid gases. This is referred to as ‘black hydrogen’. We think a 10% IRR requires a hydrogen price of $1-2/kg. But again, CO2 intensity can be astronomically high, as much as 25 tons of CO2 per ton of hydrogen (i.e., 25 tons/ton). This is 3x more than generating hydrogen from steam methane reforming of natural gas (grey hydrogen). Please see our overview of hydrogen technologies.

As part of the energy transition, preserving a future for clean coal, it is feasible to purify and dispose of >90% of this CO2 from producing black-brown hydrogen. The result is a low-carbon hydrogen resource, maybe around 0.06kg/kWh-th. It is possible. But there is a lot of CO2 to dispose of, amplifying costs. The process could be economical at around $2.5/kg hydrogen, we estimate ($22/mcf-equivalent). Details in the model. But we still prefer blue hydrogen and turquoise hydrogen as leading options.

The costs of syngas and the costs of hydrogen from coal gasification depend on input variables. Capex costs are usually around $1,000/kWth of syngas. Other inputs are coal prices, efficiency factors, chemicals costs, labor costs and other variables. These can be stress-tested in different tabs of the data-file. Data from technical papers are tabulated in half-a-dozen back-up tabs.