Water is used in heat exchangers, in data-center cooling and power plant cooling. These are interesting areas, which have featured in our research. But what opportunities to raise performance and lower water use? Ecolab water management technology monitors the composition of industrial water and then optimizes additives against scaling, fouling and corrosion. Recent patents will support the rise of AI.

Ecolab has a history going back to 1923, is headquartered in Minnesota, USA with 48,000 employees, a presence in 170+ countries, 90,000 customers, 3,000 patent families and $16bn pa of total sales in 2024. $10bn pa of sales are water-related: across monitoring, selling corrosion inhibitors and bio-treatments. These solutions are used in power plant cooling, data-center cooling, industrial heat exchangers, desalination, washing, disinfecting, clean-in-place, laundry and cleanrooms.

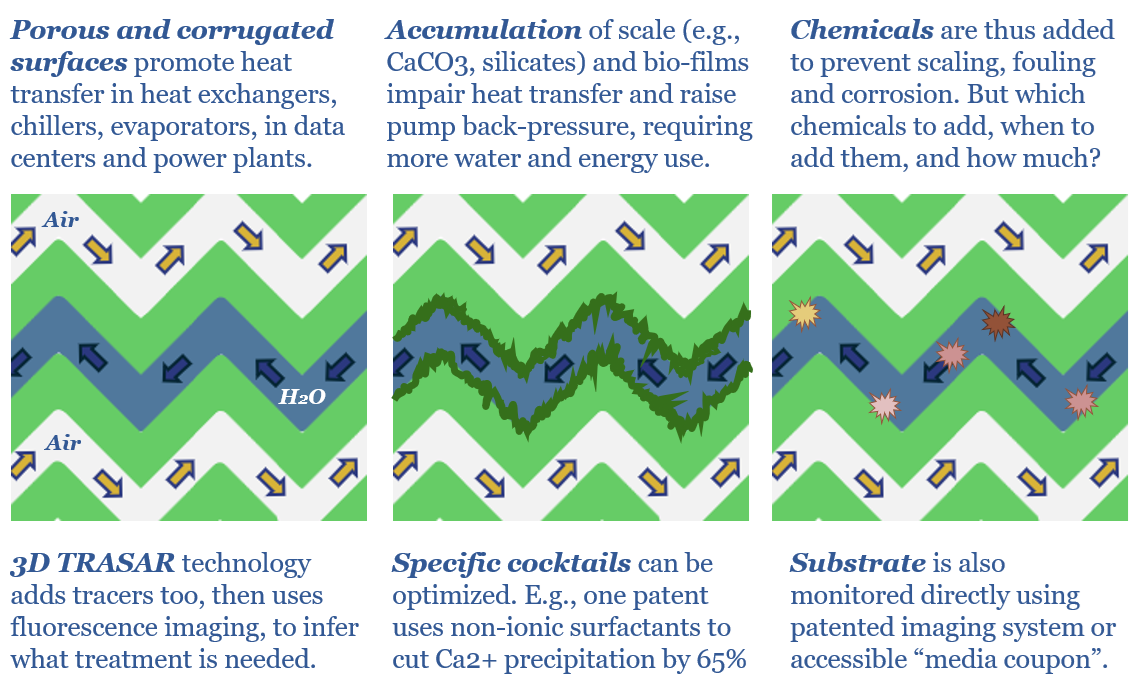

The total market opportunity for water-related equipment is quoted by the company as $150bn pa, and its share within this space is 2x higher than its next largest competitor. One reason this market exists is that scaling, fouling and corrosion can greatly reduce the performance of industrial systems that use water. An overview of some issues, and Ecolab’s water management technology is shown below.

3D TRASAR Technology is Ecolab’s water management technology platform for managing industrial assets, especially cooling systems, boiler systems, reverse osmosis and process water, to safeguard against corrosion, fouling and biological threats. It includes patented fluorescence detection hardware and software to detect system water chemistry, identify abnormal conditions and optimize chemical treatments. The 3D TRASAR Controller “precisely maintains the appropriate level of chemistries, so you will never … overfeed chemicals to a system that does not need them”.

A typical data center cooling system uses 8M gallons of water per MW per year, the company notes, hence a large data-center can use 1M m3 pa of water (250M gals pa). A typical data center is recommended to have at least 12-hours of on-site water storage for cooling towers. Efficient water management can help lower water use by one-third. Across a data-center, Ecolab claims it can save 30M gallons pa of water, 1GWH pa of energy use, 1kTpa of CO2 and $8M of value.

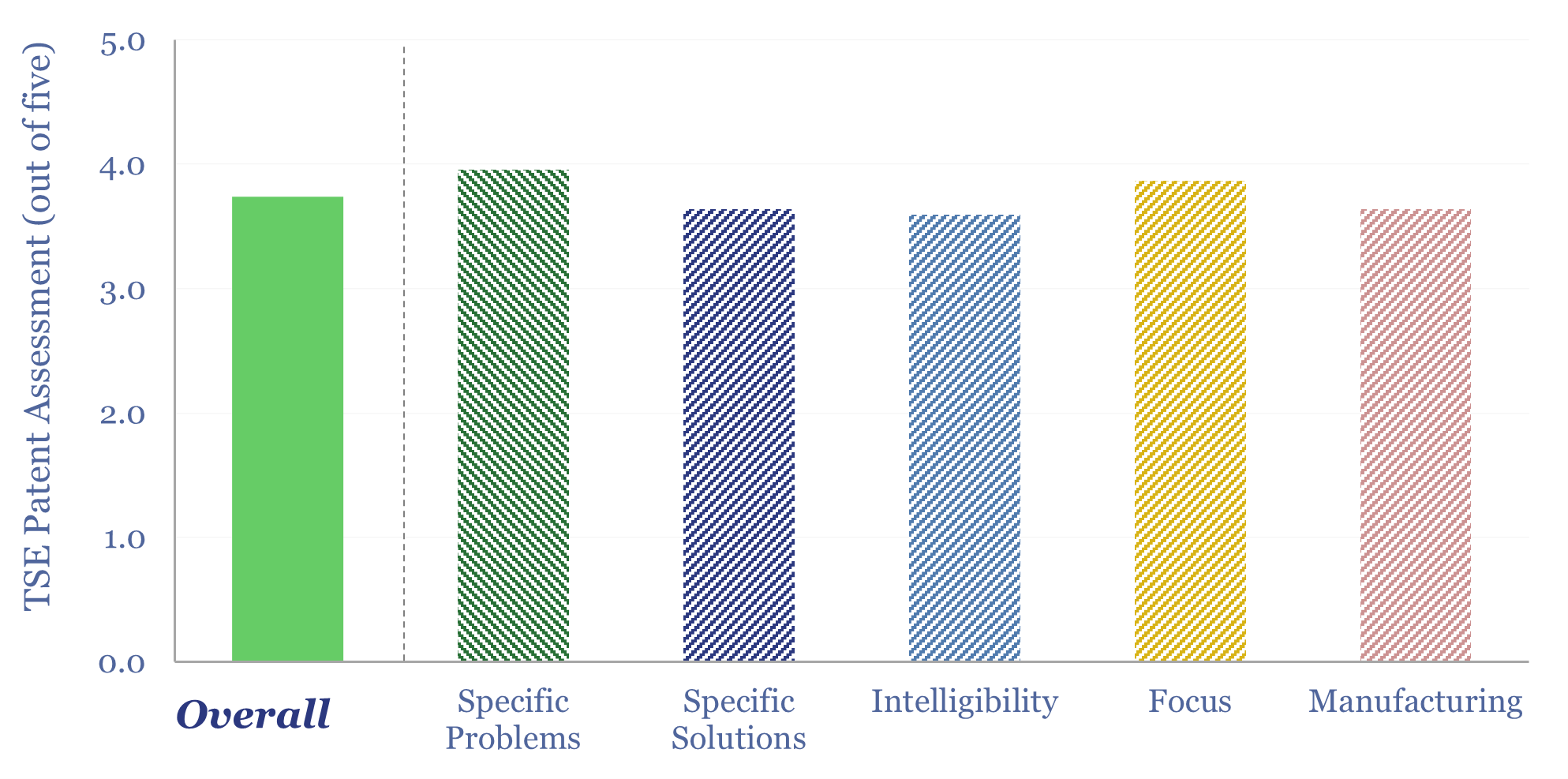

3,000 patent families are ascribed to Ecolab in Espacenet. We reviewed a sample in this data-file. We found highly specific patents aimed at maintaining heat-exchanger/cooling efficiency with additives to mitigate scaling/fouling, optimized dosing of these additives based on fluorescence imaging, and hardware to help diagnose issues. Generally, the patents were high-quality, covering specific and well-substantiated solutions, and support that Ecolab has a moat around best-in-class water management solutions for data-centers.

Patent details around Ecolab water management technology, specific cocktails of anti-scaling formulations, hardware for monitoring, and data center solutions that stood out to us are elaborated in more detail in the data-file. In particular, we found it interesting that Ecolab’s anti-scaling additives are not commoditized bulk chemicals, but highly tailored cocktails. This suggests more of a moat?