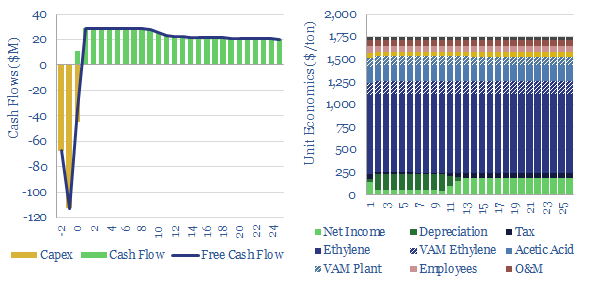

Ethylene vinyl acetate is produced by reacting ethylene with vinyl acetate monomer. This data-file estimates ethylene vinyl acetate production costs, with a marginal cost between $1,500-2,000/ton, and a total embedded CO2 intensity of 3.0 tons/ton. EVA comprises around 5% of the mass of a solar panel and could be an important solar bottleneck.

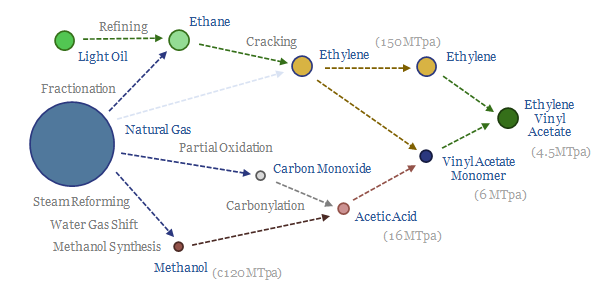

Ethylene vinyl acetate production occurs via the relatively complex pathway shown below. Natural gas liquids are fractionated into ethane. Ethane is cracked into ethylene. Natural gas is also converted into methanol. Then carbonylated with CO to form acetic acid. Acetic acid and ethylene react into vinyl acetate monomer. Ethylene and VAM are then co-polymerized into EVA. Yikes.

The key input that drives production costs of ethylene vinyl acetate is the price of ethylene. Ethylene is used both to make vinyl acetate monomer (reacting with acetic acid, in turn derived from the carbonylation of methanol) and as co-polymer in EVA itself.

As a rule of thumb, a $0.1/gal increase in the price of ethane (from our base case of $0.3/gallon) results in a $100/ton increase in the marginal cost of ethylene, which in turn results in a $100/ton increase in the cost of EVA. Hence there could be a “push” on prices from under-investment in conventional energy or in US shale.

The larger “pull” on prices is likely to come from the rapid scale-up of solar. The EVA market is relatively small, around 4.5MTpa in 2021. Whereas we think the ultimate solar demand for EVA will ramp up to 1.5-2.5MTpa (please see our solar bill of materials).

If EVA becomes a bottleneck, then solar manufacturers will have to outbid other customers for product. Another complexity is that not all EVA is inter-changeable. The solar industry uses a specialized product.

Leading EVA producers include Hanwha-TOTAL, ExxonMobil, Wacker and China’s Lianhong Xinke. Other names are noted in the data-file.

This data-file contains background notes, approximated estimates for ethylene vinyl acetate production costs, and approximated cost estimates for the underlying production of vinyl acetate monomer. We have tabulated capex costs from recent projects to inform our estimates.