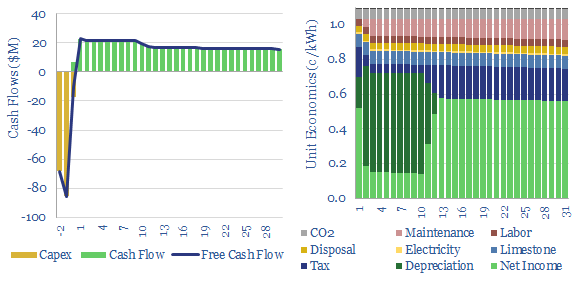

This data-file captures the costs of flue gas desulfurization, specifically the costs of SO2 scrubbers, used to remove SO2 from the exhaust of coal- or distillate-fueled boilers and burners. We think a typical scrubber will remove 95% of the SO2 from the flue gas, but requires a >1c/kWh surcharge on electricity sales in order to earn a 10% IRR.

Coal typically contains >1% sulphur (>10,000 ppm), which results in exhaust gas containing 800ppm of SO2. And higher sulphur coals contain 2-3% sulphur (data here). But global regulations increasingly limit sulphur in exhaust gases to below 50-300ppm (data here). As a result, 250 coal-fired power plants in the US alone have installed 850 flue gas desulfurization units (aka scrubbers).

Flue gas desulfurization units work by spraying a sorbent into the top of a tall exhaust stack, while exhaust gases are fed in at the bottom. The most common sorbent for desulfurization is a solution/slurry of limestone, which has previously been crushed to 5-20μm in a ball mill. CaCO3 reacts with SO2 to form CaSO3 and CaSO4 (and CO2).

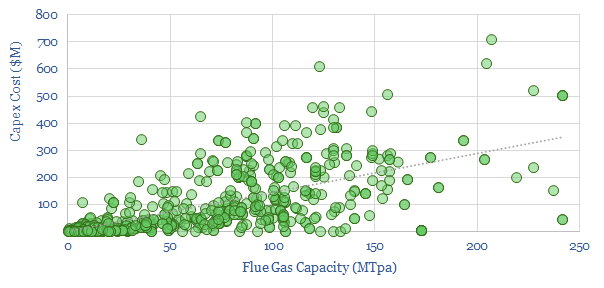

Capex costs to install a flue gas desulfurization system at a large power plant typically run to $150-300M, or $400/kW, based on useful EIA data. The costs are highly variable, and data are plotted below, correlating only loosely with the mass of exhaust gases. Recouping this capex cost with a 10% IRR adds 0.6c/kWh to the levelized cost of electricity.

Operating costs include limestone reagent, waste disposal costs, labor, maintenance and taxes. These are broken out in the data-file with sensible input assumptions.

CO2 intensity of SO2 scrubbers. 0.9 kg of CO2 is released per kg of SO2 that is captured. Substantively all of this is from the chemical reaction of SO2 with CaCO3, which releases CO2. The desulfurization plant will also have a parasitic load, but it is small, absorbing 0.1% of the coal plant’s power output. Altogether, this might add 0.03 kg/kWh to the CO2 intensity of coal power.

Levelized cost debates. One of our ongoing reasons for disliking levelized cost analysis is that comparisons are often not apples to apples. To reduce the SOx, NOx and particulate emissions of a coal plant to match a gas-fired plant is likely going to add 2c/kWh to the total levelized cost of coal power.

Diesel engines? We can also construct a variant of the model assessing the costs of SO2 scrubbers, for desulfurizing exhaust gases from diesel engines and generators. Costs are higher due to smaller scale and lower utilization, and can reach 2-3 c/kWh-u.

Companies? There is a well-diversified supply chain of companies commercializing scrubbers for onshore use. Alfa Laval, Wärtsilä, Yara are commonly cited technology providers for marine scrubbers.