A typical simple-cycle gas turbine is sized at 200MW, and achieves 38% efficiency, as super-heated gases at 1,250ºC temperature and 100-bar pressure expand to drive a turbine. The exhaust gas is still at about 600ºC. In a combined cycle gas plant, this heat can be used to produce steam that drives an additional turbine, adding 100MW of power and c20% of efficiency, for a total efficiency of 58%. This data-file tabulates the operating parameters of gas turbines, aeroderivatives, reciprocating gas engines and some fuel cells.

Why do gas turbines matter? Recuperated Brayton cycles are going to be a defining technology of the energy transition and a complement to renewables. The thermodynamics are explained here. The key point is that gas-fired power cycles are totally different from steam cycles. They run off a fuel that is 50% lower carbon than coal. They can realistically be 2-3x more efficient per unit of fuel. They are more flexible (data here). And they may also be easier to decarbonize directly (example here).

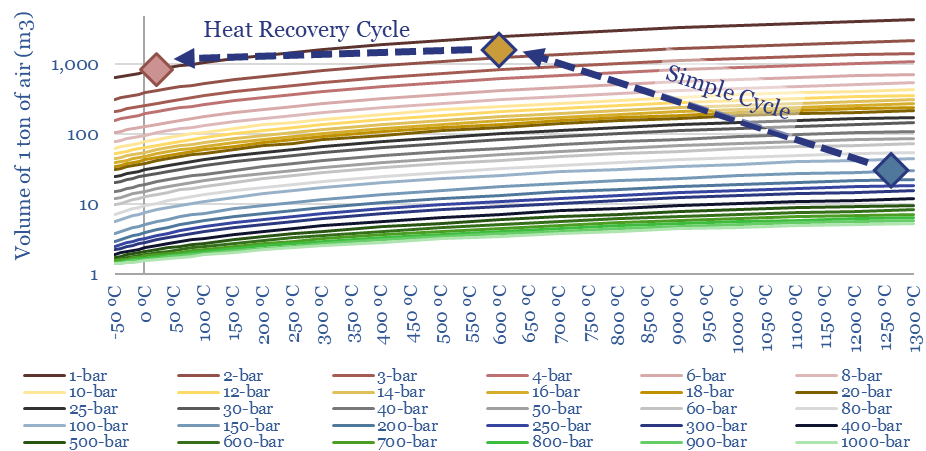

How does a gas turbine work? First, air is drawn into a compressor. The compression ratio is typically around 20x. The pressurized air is then heated by combusting a fuel. The result is a very hot, very high-pressure gas. This can be used to drive a turbine as it expands. For example, expanding 1 ton of gas from a turbine inlet temperature of 1,250ºC and a turbine inlet pressure of 100-bar, down to an exhaust gas temperature of 600ºC and near-ambient pressures, might see volumes increase by around 25x (chart below).

Simple cycles versus combined cycles. If the 600ºC exhaust gas is simply discharged into the atmosphere, then a typical simple cycle gas turbine will achieve 38% efficiency, converting natural gas into electricity. But there is still a lot of energy in a 600ºC exhaust stream, which can be used to evaporate water, produce high-pressure steam, and then drive an entirely separate turbine. This is a combined cycle configuration. And it adds another 20% efficiency, yielding a total efficiency of 58%.

Note that the steam cycle described above, powered by the waste heat from a gas turbine, is effectively the same as the primary heat cycle used in other conventional thermal power plants (Rankine cycle).

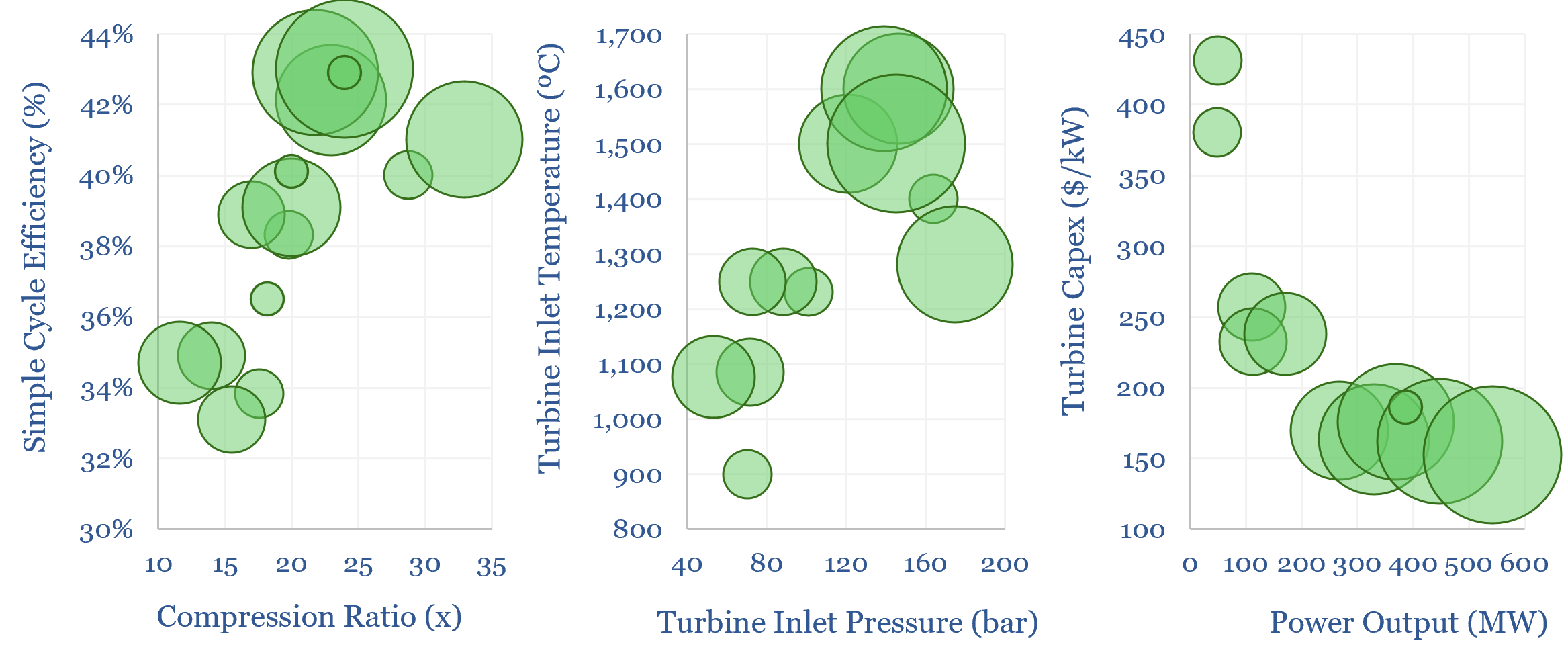

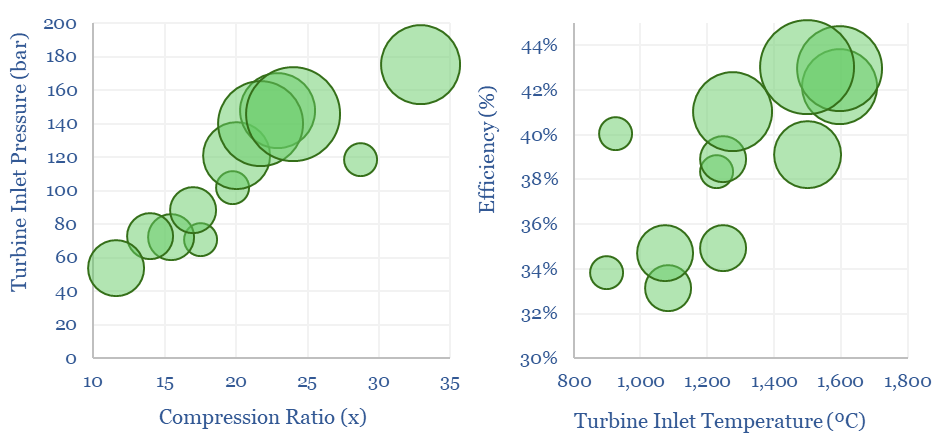

The efficiency of a simple cycle gas turbine depends primarily on the turbine inlet temperature and pressure, which in turn depend on the compression ratio. The most efficient simple cycle gas turbines hit 43% efficiency, with compression ratios of 25-30x, turbine inlet pressures of 140-180 bar and turbine inlet temperatures of 1,400-1,600ºC. It is quite hard to get hotter than this, because things start to melt. But consider, for contrast, that a steam cycle really struggles to surpass 300-500ºC.

Why does a gas turbine look like that? To achieve these high compression ratios, a typical gas turbine will have 12-22 separately optimized and sequential compression stages. And to maximize power output in the turbine, it will typically have 4 turbine stages. This explains the classic cross-sectional profile of a gas turbine.

How fast does a gas turbine spin? A simple cycle gas turbine typically spins at 3,000-4,000 revolutions per minute (rpm). The compressor is connected to the same shaft as the turbine. The back-work ratio imparted to the compressor is equivalent to around 40-50% of the net work driven through the turbine.

How large is a gas turbine? A typical 200MW gas turbine might take up 60 m2 and weigh 300 tons. Good rules of thumb are 0.3 m2/MW of areal footprint, and 2 tons/MW of weight. Although larger gas turbines are more compact (on a per MW basis), and power plants are much more sparsely distributed.

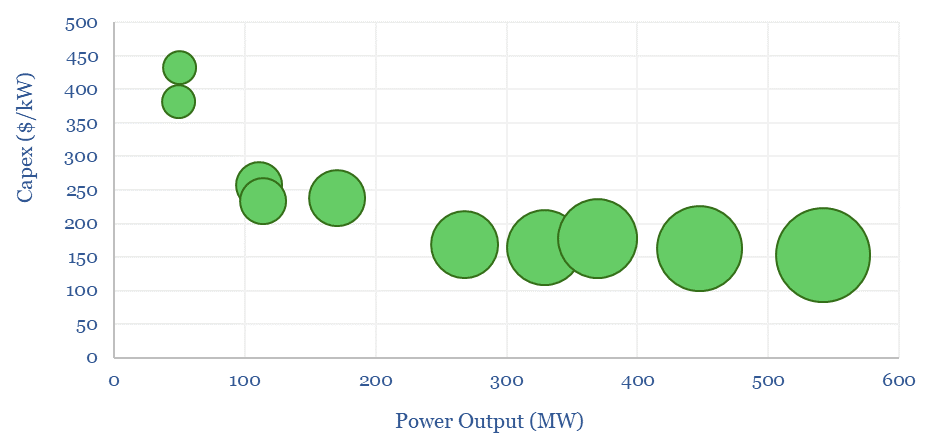

What is the cost of a gas turbine? A typical gas turbine might cost $200/kWe (chart below). Larger gas turbines have lower costs per MW (chart below). However note that in our model of a gas-fired power plant, total installed capital costs are typically around 4x larger than the turbine itself.

(This multiple may be worth keeping in mind amidst debate about hydrogen electrolyser costs. Some companies have been guiding to $200-300/kWe electrolyser selling prices, and some analysts noting that this realistically means around $1,000-1,200/kW fully installed costs).

Emissions from natural gas power plants are generally low. CO2 intensity is 0.3 kg/kWh from a 60% efficient combined cycle gas turbine (up to 70% below coal power plants). NOx emissions are usually below 25ppm but can be as low as 2ppm in the best models. Many new turbines are also hydrogen-ready, and have been qualified for 25-75% hydrogen blending.

Flexibility of a gas-fired power plant is middling to high. A typical plant can ramp up or down by 15% of its nameplate capacity per minute, turn down to c25-50% of its load, and start up from cold in 20-minutes. Different examples are tabulated in the data-file.

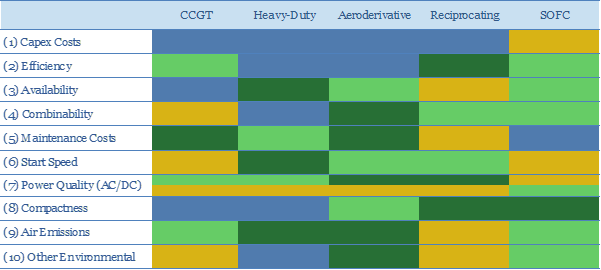

The full data-file compares the typical operating parameters of heavy-duty gas turbines, CCGTs, aeroderivative turbines, reciprocating gas engines and solid oxide fuel cells. Numerical values are given across all of the dimensions below: capex costs, efficiency (including at part load), availability, combinability, maintenance costs, start-up speeds, power quality, space requirements, air emissions (NOx, CO, particulates), water intensity and noise in dB.

Our outlook for gas turbines in the energy transition is published here. Leading companies in gas turbines are profiled here. Gas turbine operating parameters are compiled for a dozen gas turbine models in this data-file, as a useful reference, mainly designs from Siemens Energy, GE, Mitsubishi-Hitachi and Ansaldo.