This data-file compares the costs of refrigerant compression systems at LNG plants, across gas turbines, electric motors powered by CCGTs, or electric motors powered by renewable electricity. eLNG costs are higher, in capex terms, but this is balanced by lower opex. Payback times are short. Numbers in $/mcf and $/MTpa can be stress-tested in the data-file.

LNG liquefaction plants chill methane to -160C as refrigerant gases (nitrogen, propane) expand. Subsequently, around 300kWh/ton of useful energy is needed to recompress the refrigerant gases, so they can be recirculated and provide further cooling. Energy economics are built up from first principles in our overview of LNG liquefaction technologies.

Refrigerant compression is traditionally achieved via large centrifugal compressors, whose drive shafts are energized by burning gas in a directly coupled gas turbine. However, eLNG is also accelerating as an alternative, using electric motors instead of gas turbines.

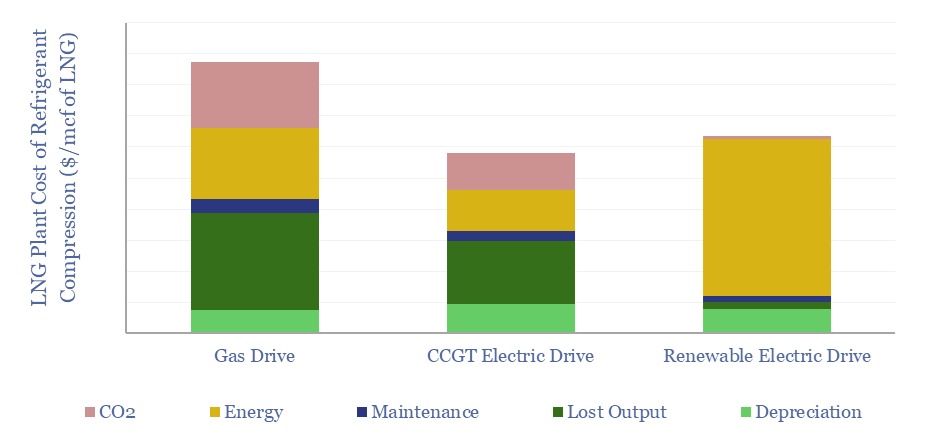

This data-file compares the costs of gas-driven compression versus electric motor compression, either energized via on-site CCGTs, or via transmitting renewable electricity to the LNG plant. The costs depend on gas prices, electricity prices, incremental production, lower maintenance costs and CO2 prices (if applicable).

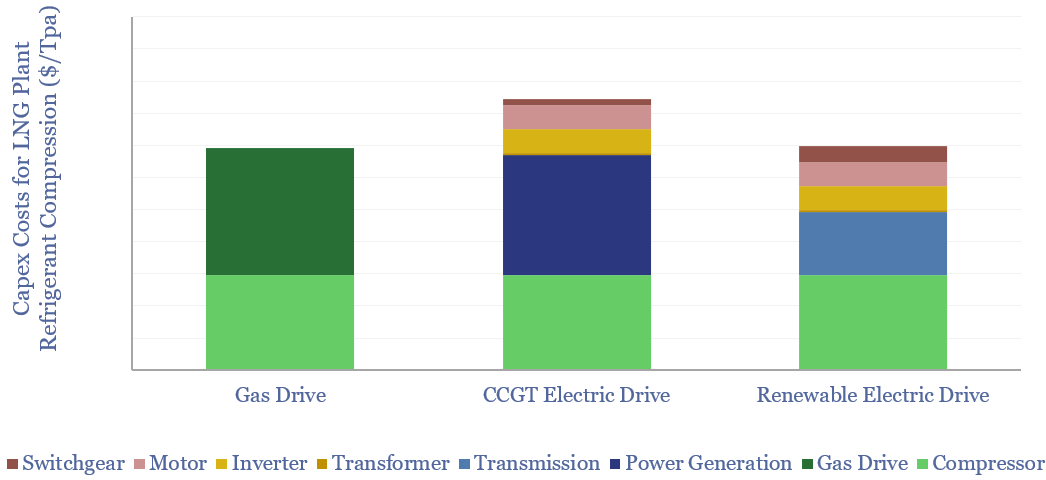

Capex costs of eLNG systems (i.e., electric motors for LNG refrigerant compression) will generally be up to c20% higher than for gas driven systems. Numbers are built-up from first principles in this data-file, and hinge on our other economic models, e.g., for transmission lines, compressors, electric motors and inverters.

Electric motors energized by CCGTs seem to be the most economical solution in our build-up, and can result in $0.15/mcf lower total costs of delivered LNG, while saving up to 80kTpa of CO2 per MTpa of LNG, due to higher efficiency. Higher up-time for a CCGT versus an aeroderivative gas turbine would also contribute to more LNG revenues.

Fully electric LNG trains, energized by renewable electricity, especially hydro, can eliminate the vast majority of the compression emissions associated with LNG liquefaction. This can also be cost-effective, if low-cost renewable electricity can be brought to the site, and if a c$50/ton CO2 price is applicable or can be passed on to LNG buyers.

Relative advantages of eLNG concepts, i.e., energizing electric motors for the refrigerant compression at LNG plants, were discussed in our recent research note, linked below. Please also see our LNG plant economic model and broader LNG research.