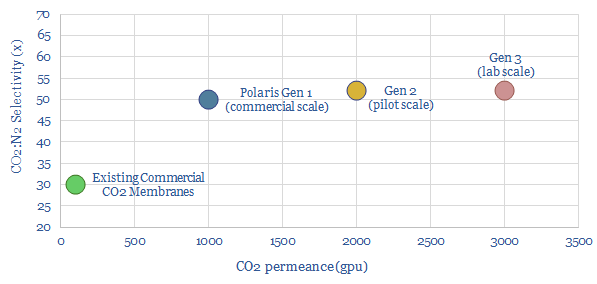

Membrane Technology and Research Inc. (MTR) is a private company, based in California, founded in 1982, specializing in membrane separation systems, for the energy industry, chemicals and increasingly, CCS. Its Gen 2-3 Polaris membranes have 50x CO2:N2 selectivity, 2,000-3,000 GPU permeabilities, and have been piloted successfully, reaching TRL 6 by 2023. Our technology review is mixed, including interesting details around sweep gas recirculation.

Next-generation membranes for carbon capture could separate out 95% of the CO2 in a flue gas, into a 95% pure permeate, for a cost of $20/ton and an energy penalty below 10%. This is better than the best amines. We recently explored this opportunity in a detailed research note, which posed ten criteria for a breakthrough in membrane CCS, backed up by an economic model here.

Membrane Technology and Research Inc. has developed a membrane system called Polaris, with 50x CO2:N2 selectivity, and very high permeability, reaching 2,000-3,000 GPU in Gen 2-3 designs.

A small pilot test has been conducted at NCCC, in Barberton OH, in 2016, recirculating gas to a boiler operating on natural gas, Powder River Basin coal and Eastern Bituminous coal. No burner modifications were required. Air sweep ranged from 500-2,300 lbs/hr. Oxygen in the boiler was 17-21%. Capture rates reached 90%. There was minimal impact on CO, SO2 or NOx formation.

In 2021-22, MTR’s Gen-2 Polaris membrane-frame modules were also tested at Technology Centre, Mongstad (TCM), for 2,200 hours, using a feed of flue gas from the refinery’s FCC unit; capturing 61-91% of the CO2 at 92% dry purity, from 14-25% CO2 slipstreams (after recirculation), with pressure drops of 2kPa. Off the back of these results, a 150-200 Tpd pilot in 2023-24 at the Wyoming Integrated Test Center will reach TRL 7 by the mid-2020s.

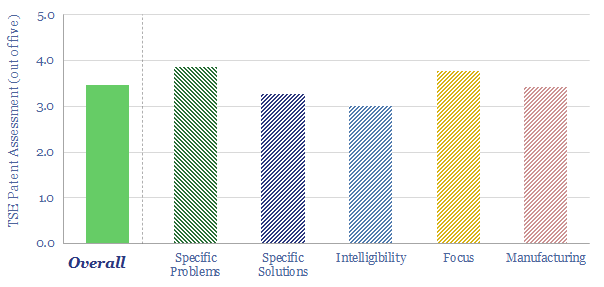

So how does Membrane Technology and Research Inc.’s membrane technology work? To answer this question, we have reviewed 22 patents in this note, finding mixed results on our usual patent framework. Details are in the data-file.

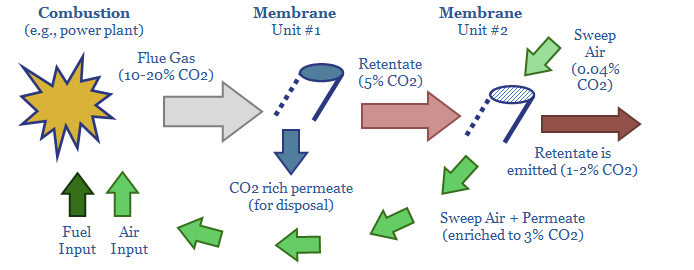

The most interesting innovation, which we think is well locked up by the patents through the early 2030s, is the use of a sweep gas recirculation system, which allows a membrane with a “mere” 50x CO2:N2 selectivity to remove as much as 90% of the CO2 from an exhaust gas, which would otherwise be impossible with a single membrane pass.

After the first membrane pass, the retentate is flowed into a second membrane unit, where CO2 permeation is enhanced by a “sweep gas” of air (0.004% CO2) on the permeate side. This CO2-air mixture is then circulated back into the combustor, so post-combustion CO2 concentrations will be enriched, and this CO2 has another chance to be captured by the first membrane unit (chart below).

What type of membrane does Membrane Technology and Research Inc. use? Our patent screen found descriptions of a polyamide-polyether block copolymers, fluorinated polymers, and underlying support layers with improved manufacturing methods that promote more even pore distributions. Further details are in the data-file.