Metal organic frameworks (MOFs) are an exciting class of materials, which could reduce the energy penalties of CO2-separation by c80%, and reduce the cost of carbon capture to $20-40. This data-file screens companies developing metal organic frameworks, where activity has been accelerating rapidly, especially for CCS applications.

Sorbents are classes of materials that are useful for separating industrial mixtures, as they adsorb some compounds but not others. They can be disposed on specialized membranes, or in tanks, where compounds can be adsorbed and later desorbed by pressure swings.

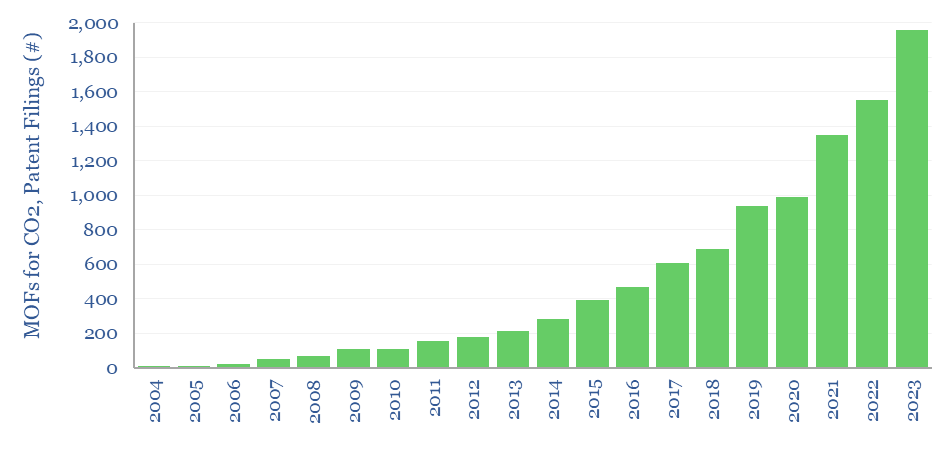

Metal organic frameworks could be particularly useful for CCS or DAC. Today’s CCS and DAC processes are only 5-10% efficient, compared to their thermodynamic minimum energy, and we increasingly wonder whether AI engines can help develop sorbents with materially better performance. Hence, the number of patent filings into MOFs has been rising at an exponential pace, growing at 25% pa in the past decade.

The state space of metal organic frameworks is very large. MOFs were first described 20-years ago by US chemist Omar Yaghi. Over 40,000 MOFs had been identified mid-2018. Over 90,000 have been identified by 2021. The total state space reaches 10^16.

Metal organic frameworks can also be highly porous. Some fit the entire surface of a football field into a teaspoon of powder weighing less than 1 gram, e.g., 10,000 m2/g, which is c1,000x a typical zeolite.

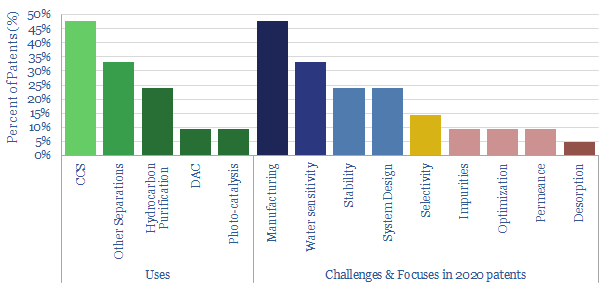

The challenge is finding MOFs that are stable and water-resistant, then synthesizing them in continuous, mass-scale processes that do not require expensive solvents. In an earlier iteration of this data-file, we tabulated the challenges for MOFs, based on patent filings.

Costs of metal organic frameworks, for example, are in the range of $10-70/kg, which is 1-2 orders of magnitude more expensive than today’s commercial zeolites, such as 13X, which typically range from $1.5-3/kg (tabulated here). However, the high costs can be compensated by higher performance and porosity.

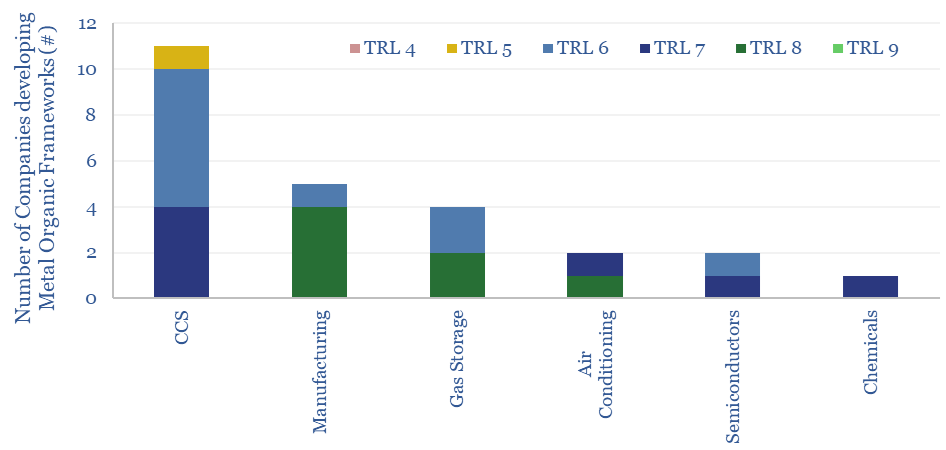

This data-file screens companies developing metal organic frameworks, based on their disclosures, news flow, patents and partnerships. Most are small, private companies, founded in the last decade. Yet momentum seems to be building, especially for using metal organic frameworks in CCS applications, most famously by Svante.

Recently, we have also screened exciting progress from Montana Technologies, using metal organic frameworks to lower the energy costs of air conditioning units by 50-75%.

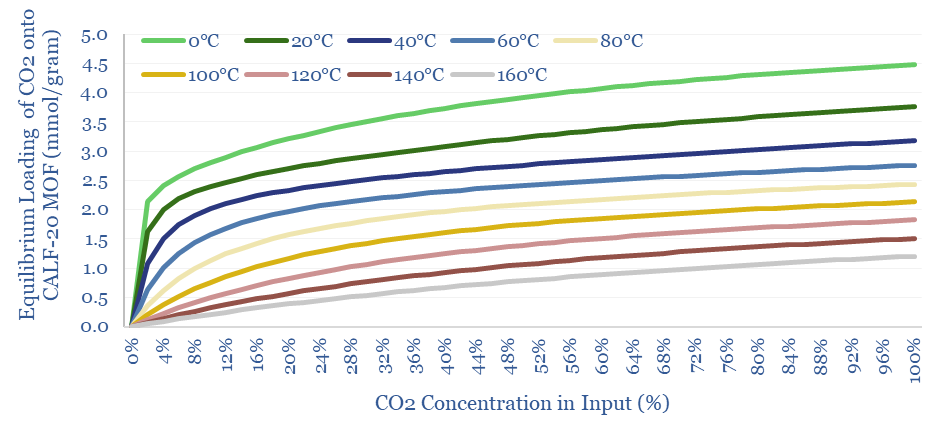

Also included in this data-file are our notes from technical papers, and an economic model for MOF-based CCS, which can bridge to CO2 capture at around $40/ton, due to lower complexity and lower energy penalties than amine-based CCS. It has been quite nice to take this analysis back to first principles, including Langmuir Isotherms and MOF capture rates (tons of CO2 per kg of MOFs per year) as inputs.

Full details on the different companies developing metal organic frameworks, and their underlying progress is in the data-file.