Swing Adsorption separates gases, based on their differential loading onto zeolite adsorbents at varying pressures. The first Pressure Swing Adsorption (PSA) plant goes back to 1966. Today, tens of thousands of PSA plants purify hydrogen, biogas, polymers, nitrogen/oxygen and possibly in the future, can capture CO2? This 16-page note explores PSA technology, costs, challenges, leading companies and disruption of industrial gases.

Gas separations matter as many industrial processes require pure input streams. Industrial hydrogen must be purified from a soup of gases exiting a methane reformer. Polymers and other advanced materials require separating olefins from the outputs of crackers. Other important separations include air separation, gas processing and possibly also CO2 separations for CCS. Industrial examples are discussed on pages 2-4.

Pressure Swing Adsorption works by harnessing different products’ different affinities to adsorb onto zeolites at different pressures and temperatures. If you want to understand how much gas adsorbs onto a zeolite, we cover the basic theory of Langmuir Isotherms (pages 5-6), and more advanced models such as the Sips model (page 7).

Zeolites and activated carbon are two classes of materials that can be used as adsorbents. Zeolites are crystalline aluminosilicates. 40 occur naturally and 250 total structures have been synthesized (page 8).

Separating hydrogen from reformer gases? Separating hydrogen from SMR syngas might cost $0.06/kg for 95-99% pure H2, with 85-95% recovery, based on our PSA economic models. The breakdown of costs, and other sensitivities, are discussed on pages 9-10.

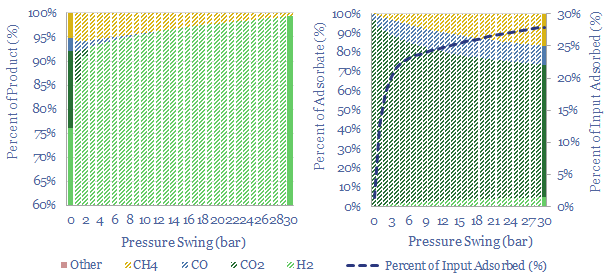

Separating biomethane from biogas? Separating biomethane from biogas and landfill gas could use pressure swing adsorption, but we find the thermodynamics and costs to be more challenging, per page 11.

Separating CO2 from exhaust gases? Separating CO2 from exhaust gases could use pressure swing adsorption, but we find the thermodynamics and costs to be even more challenging again, per page 12. Although this may change in the future, with next-gen adsorbents?

What excites us most about PSA is the possible energy savings compared to other separation technologies, and the growing capability to backstop volatile renewables (demand shifting). Compressors and vacuum pumps are simply more flexible than cryogenics, per pages 13-14.

Leading companies in Pressure Swing Adsorption are discussed on pages 15-16, including the usual suspects in Industrial Gases, and how many PSA plants they have constructed historically. PSA is especially important in future blue hydrogen value chains, from production to distribution (page 15).

Disruption of the air separation industry? There is also a stream of new entrants, including a large, listed Capital Goods giant, looking to use PSA for air separations, instead of cryogenics. Energy costs can be materially lower, and flexibility to backstop renewables can be materially higher, versus incumbent air separation technologies (page 16).

Pressure swing adsorption is an important tool for industrial separations, alongside amine separations, membrane separations and cryogenic separations, as covered in our broader research. For access to all of our research, please contact us about a TSE subscription.