Cryogenic air separation is used to produce 400MTpa of oxygen, plus pure nitrogen and argon; for steel, metals, ammonia, wind-solar inputs, semiconductor, blue hydrogen and Allam cycle oxy-combustion. Hence this 16-page report is an overview of industrial gases. How does air separation work? What costs, energy use and CO2 intensity? Who benefits amidst the energy transition?

As compressed gases expand, they will tend to cool down, via the Joule-Thomson effect. We think it is helpful for energy decision-makers to understand this theme, as it underpins fridges, air conditioners, heat pumps, LNG and industrial gases.

Industrial gases comprise a market worth c$100bn per year, including 400MTpa of oxygen. And a surprisingly large number of metals, materials and decarbonization technologies use industrial gases. For example, blue hydrogen ATRs and Allam Cycle oxy-combustion are both oxygen-fired. An overview of industrial gas demand is given on pages 2-3, and demand from new energy transition technologies is reviewed on page 4.

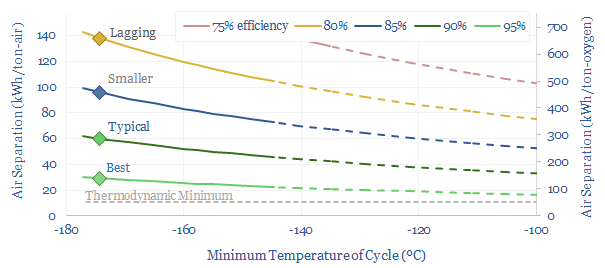

The thermodynamic minimum energy demand to separate oxygen from air is 51 kWh/ton. But how realistic is it that real-world processes will ever reach this theoretical level? Our answer is on page 5.

Real world cryogenic processes achieve cryogenic air separation via the Reverse Brayton Cycle. We explain how this thermodynamic cycle works on page 6, and quantify real-world energy costs (in kWh/ton) from first principles on page 7.

Air Separation Unit (ASU) designs are reviewed on pages 8-9, including the key components of real-world plants, and what determines their capex (in $/Tpa).

Costs of industrial gases are discussed on pages 10-11, including our best estimates of base case IRRs (%), costs of different gases (in $/ton) and the cost drivers. Raising energy is often possible, but not always economical. And can ASUs ‘demand shift‘, backstopping renewable heavy grids like batteries, by scaling up and down to smooth out an increasingly volatile power grid?

What implications for blue hydrogen, green hydrogen, Allam Cycle oxy-combustion, direct air capture energy economics? Some important conclusions are noted on page 12.

Leading companies in industrial gases are discussed on pages 13-14. Our company screen is linked here. We wonder whether reliability, scale and quality lead to sustainably higher margins?