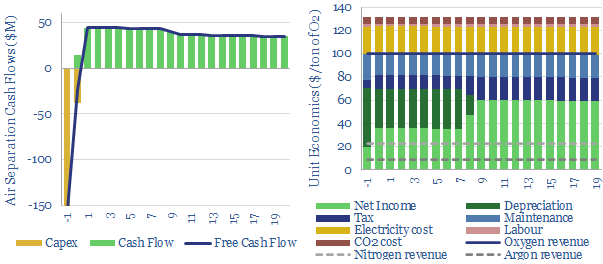

This data-file calculates the costs of cryogenic air separation units, which are important in the production of industrial gases, ammonia, metals, materials, medical applications and new energy technologies such as blue hydrogen. Good base cases are $100/ton oxygen, $20/ton nitrogen, $200/Tpa capex and 60kWh/ton of electricity (on an input air basis).

Cryogenic air separation was first studied by Carl von Linde, in 1895, and commercialized in 1902 in tiny 0.1Tpd production facilities.

Modern plants tend to produce 200-40,000nm3/h of oxygen and 1,000-150,000nm3/h of nitrogen, by liquefying air and then boiling off its constituents.

The main heat exchanger in a cryogenic air separator is usually a plate and fin design, super-chilling air to -172C. From the heat exchanger, the liquid air is transferred to a double-column distillation block. The boiling point of nitrogen is -196C, while the boiling point of oxygen is -183C.

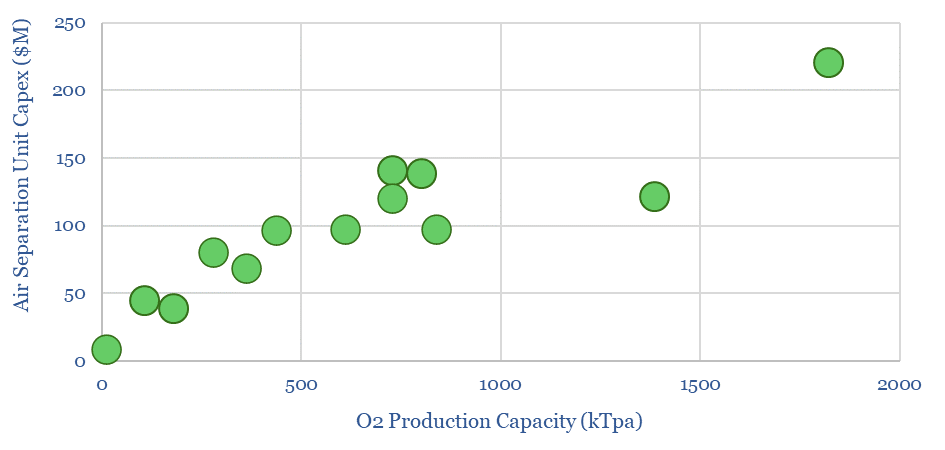

Capex costs of air separation units are aggregated in the data-file, but a good average is around $200/Tpa of oxygen capacity.

Energy consumption of air separation units is also estimated in the data-file, ranging from 150-800 kWh/ton of oxygen. The numbers can vary. Our estimates are built up using both bottom-up thermodynamic calculations, and a survey of data-points reported by companies and technical papers, tabulated in the data-file.

We estimate an oxygen price of $100/ton is sufficient for a new air separation unit to generate a 20% IRR. However, this includes help from selling nitrogen and argon.

We estimate a nitrogen price of $20/ton is required for an air separation unit that feeds into an ammonia plant and derives some revenues from commercializing oxygen and argon as well.

Sensitivity of costs to underlying input assumptions? You can stress-test the economic sensitivities in the data-file, including capex costs, opex costs, electricity prices, etc.

A large share of costs comes from electricity. Hence there may be some scope to vary compressor loads at air separation units flexibly to absorb intermittent renewables (note here).

There are also interesting technologies to replace some cryogenic separations with lower-cost and less energy-consuming membrane technologies.

Leading companies in cryogenic air separation are screened here, and include Linde (4,000 air separation plants built worldwide) and Air Products (1,200 plants built) and also Air Liquide.