Costs of paper production are estimated at $700/ton, at a $2,000/Tpa paper mill, requiring 5,000 kWh/ton of useful energy, and emitting 2.6 tons/ton of CO2, of which 2.2 tons/ton is likely sourced from burning organic material such as waste wood and black liquor. This data-file captures the energy economics of paper production.

Paper is made by chopping down trees, shredding the logs, boiling this sawdust in a cocktail of chemicals (e.g., sodium hydroxide, sulphides) at 150-175ºC for several hours to extract the cellulose fibers, refining this fibrous slush, then rolling it out into sheets, pressing out some of the water and heating out the rest.

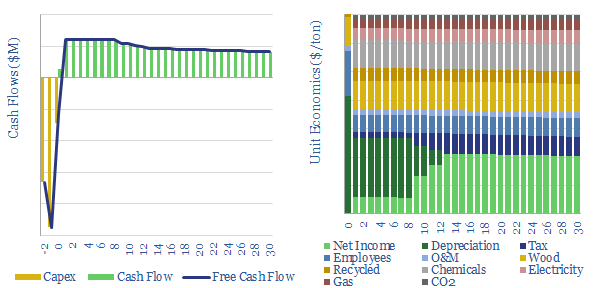

Our model captures the energy intensity, cost breakdown and economics of this process. We think a large new integrated paper mill must charge around $700/ton for a 10% IRR.

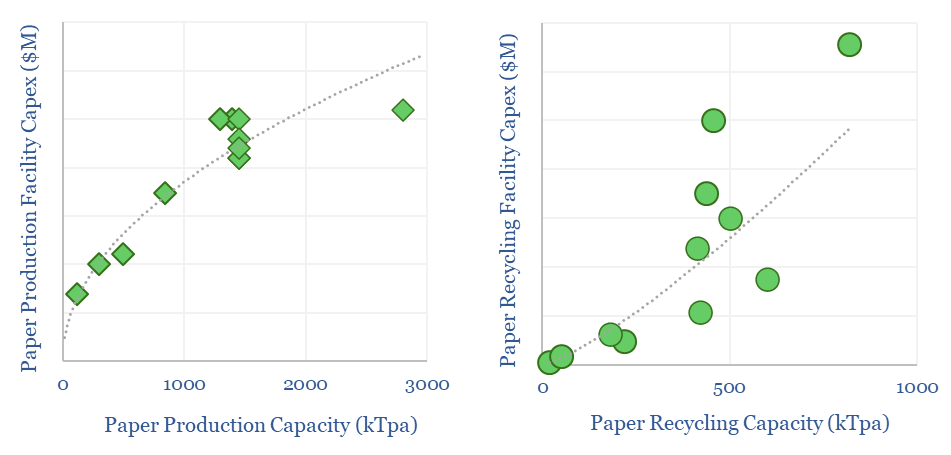

Capex costs of paper production facilities are estimated on a top-down basis in the model, for both primary paper production and for recycling.

The controversy is the CO2 credentials of wood. Total energy intensity of paper production is built up across 18 separate lines in the model, and usually comes in around 5-6MWH per ton of paper, of which one-third is from external energy sources (e.g., electricity, gas, coal) and two-thirds is from burning bark and other waste wood residues.

IPCC protocols only count the emissions from external energy, suggesting CO2 intensity around 0.4 kg per kg of paper. However, if you believe that chopping down a tree and burning two-thirds of the wood does in fact release CO2 into the atmosphere, then the total CO2 intensity is closer to 2.6 kg CO2 per kg of paper (comparable to plastics).

We are all somewhat complicit in these emissions, as the average Western person consumes 200kg of paper per year in various forms, underpinning around 0.5 tons of CO2 emissions per person per year from consuming paper products alone.

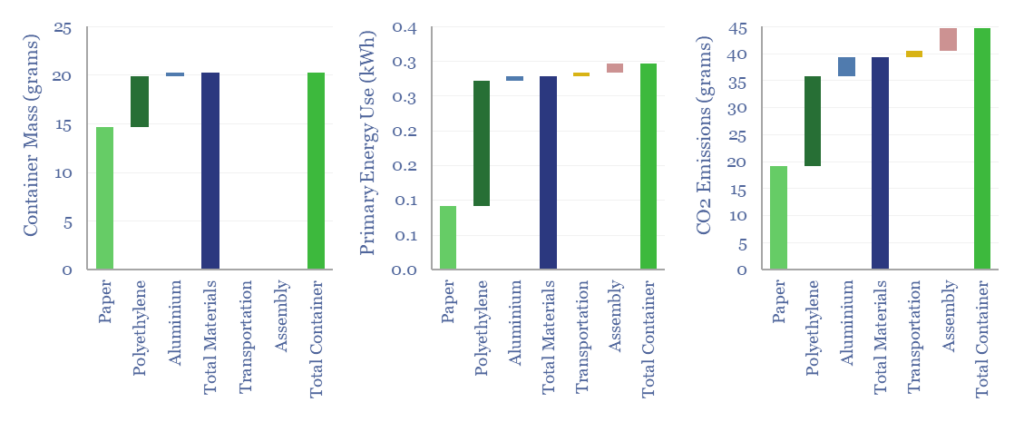

Nevertheless, paper packaging has the lowest embedded energy cost and lowest embedded CO2 emissions, of other packaging materials. Our base case is that a 500ml paper beverage container (which is strictly a mixture of 72% paper, 26% polyethylene film and 2% aluminium) embeds 0.3 kWh of primary energy and emits 45 grams of CO2 up until the point of use (chart below), which is less than our emissions build-up for packaging materials such as PET, aluminium and especially glass.

Numbers in the paper value chain are sensitive to input assumptions, such as wood prices, capex costs, energy prices, opex costs, treatment of emissions, and other input variables, which can all be stress-tested in our model into the costs of paper production.