Our Plug Power technology review is drawn from the company’s recent patent filings, which offer some of the most detailed disclosures we have ever seen into the manufacturing of PEM electrolysers and fuel cells, underlying catalyst materials, membranes and their manufacturing. One patent seems like a breakthrough. Other patents candidly presented challenges for scaling up green hydrogen and raised questions for us.

Plug Power is a green hydrogen company, founded in 1997, headquartered in New York, with 3,350 employees and c$5bn market cap in mid-2023.

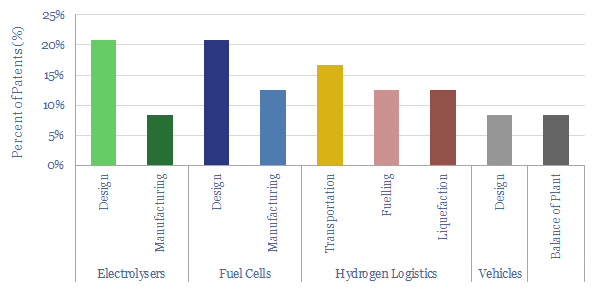

Plug Power is aiming to scale up as a world-leading supplier for $20bn pa of equipment and services across the end-to-end green hydrogen ecosystem by 2030: from electrolysers, to logistics, to energy generation in fuel cells, and niche applications such as forklift trucks (where it has an incumbent position, underpinning c30% of 2023’s revenue targets).

For an overview of how a Proton Exchange Membrane electrolyser works, we have written a short article here. We have not been able to de-risk much green hydrogen in our roadmap to net zero, due to challenges of cost, efficiency, degradation and practicality, as catalogued here.

But on the other hand, Plug Power’s share price has declined by 85% from its 2021 peak, and the purpose of our patent reviews is to stress test our pre-existing conclusions, to see what we could be missing.

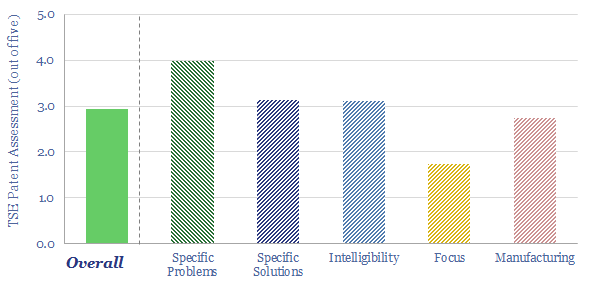

Overall the patent library was very broad ranging (chart below), and raised some question marks for us around where the ‘focus’ and ‘moat’ really are in the business. More discussion in the data-file.

Half a dozen recent patents may offer some support to Plug’s mass manufacturing ambitions. Some of these patents contain the most detail we have ever seen on how electrolyser membranes are manufactured, how anode catalysts are synthesized, materials used in different components of a fuel cell stack, and where the pinch points currently are in manufacturing.

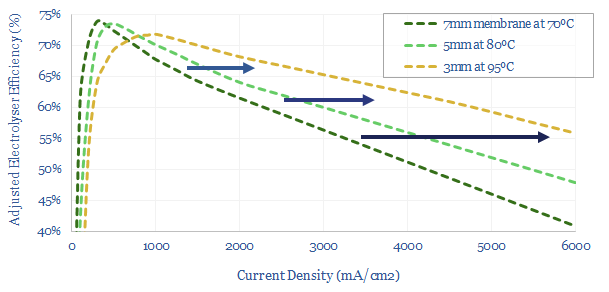

The most exciting Plug patent that crossed our screen during this review discusses a ‘dry’ manufacturing process for PEM electrolyser membranes, unlocking lower uses of precious metals (especially platinum) and thinner membranes at higher temperatures, which in turn could improve output and efficiency, and thus deflate electrolyser costs (details in the data-file).

Generally the patents did not contain the same focus on avoiding degradation, as for example, the recent patent library from Bloom Energy.

Further details and conclusions that stood out to us from our Plug Power Technology Review are available in the data-file.