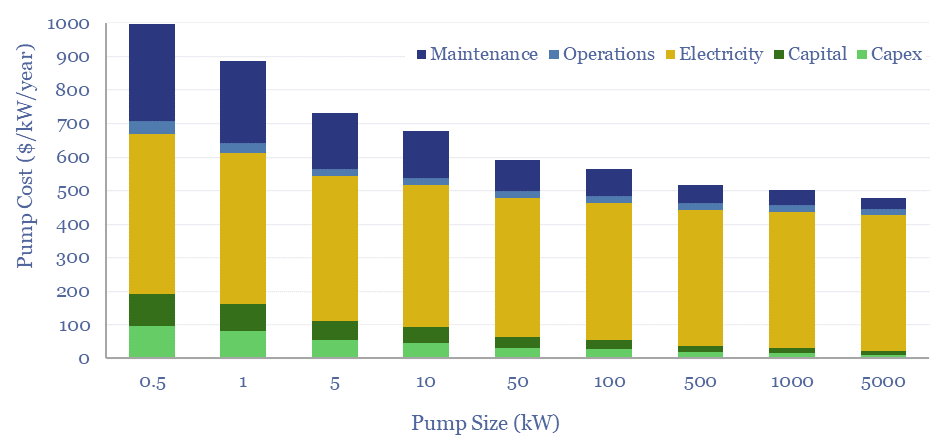

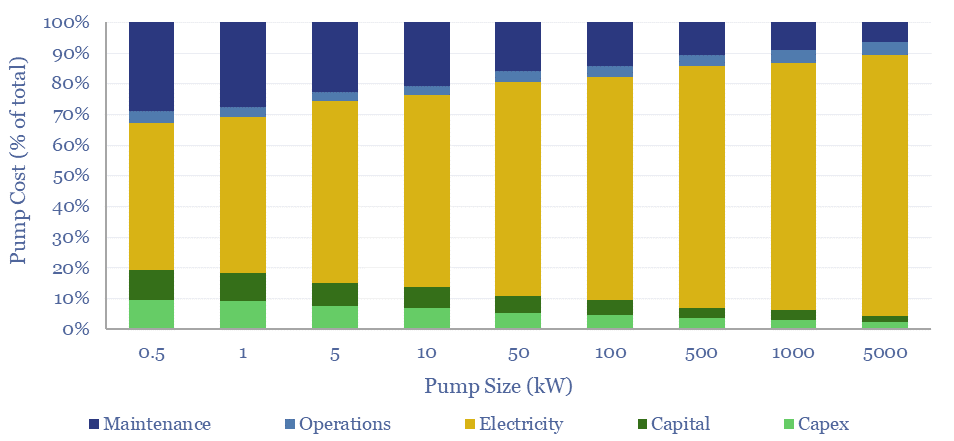

Total pump costs can be ballparked at $600/kW/year of power, of which 70% is electricity, 20% operations and maintenance, 10% capex/capital costs. But the numbers vary. Hence this data-file breaks down the capex costs of pumps, other pump opex, pump energy consumption and the efficiency of pumps from first principles.

This data-file captures the energy economics of electric pumps, which are used to move liquids in industrial applications, for commercial/domestic use such as within heat pumps, for demand shifting, for supercritical CO2, in geothermal applications, and in 15-20% of the world’s 1M oil wells globally (electric submersible pumps, or ESPs).

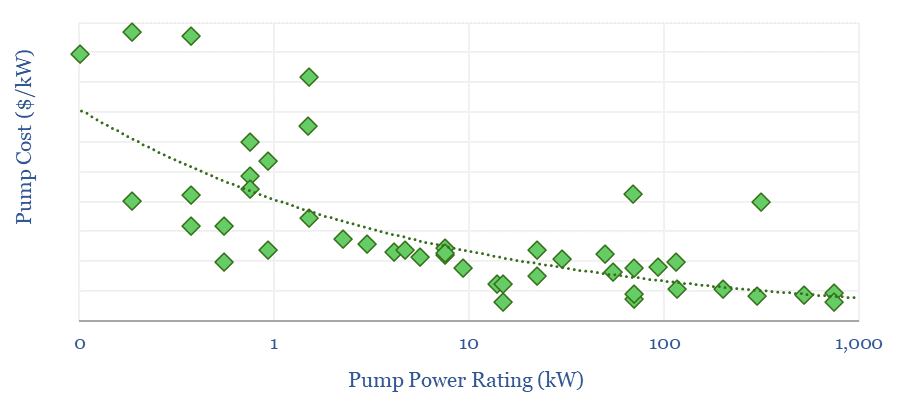

The capex costs of a pump are estimated from fifty commercial data-points, in $/kW, and a line of best fit suggests that pump costs approximately halve as pump size increases by 10x (chart below). In other words, larger pumps are less costly per kW of power.

Total pump costs, however, are usually only 5-20% capex, while the largest costs are for electricity use, at 50-90% of the total, depending on the pump size and utilization rate (chart below). All of these variables can be stress-tested in the ‘PumpModel’ tab.

The power consumption of a pump is modeled from first principles, using the formula that pump power consumption (in kW) equals flow rate (in m3/second) times back-pressure (in kPa) divided by pump efficiency (in %). The ‘PumpEnergy’ tab contains a simple and flexible calculator for pumping power (in kW).

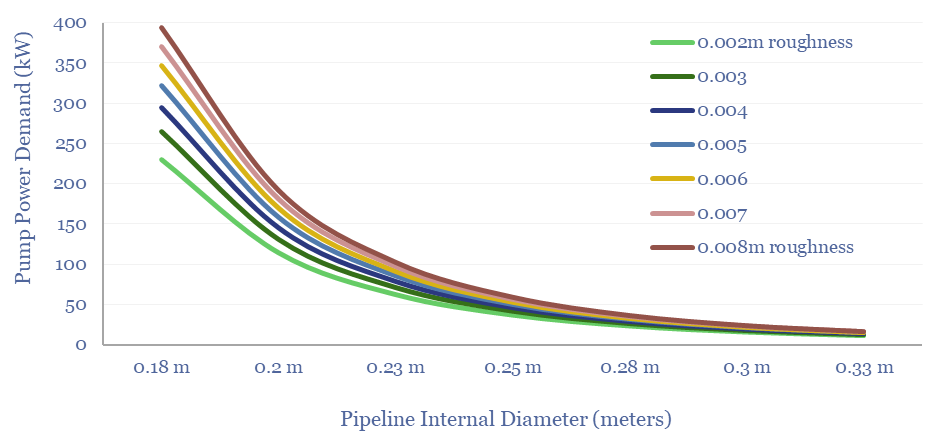

Back-pressure on a pipeline, in turn, is the sum of static head (overcoming gravity), dynamic pressure (overcoming inertia) and head losses (calculated using the Darcy-Weisbach and Colebrook Equations from flow speed, Reynolds Numbers, pipeline diameter and pipeline surface roughness).

Energy costs of a pump are best minimized by using wider pipes with smoother internal surfaces (chart above). But these pipes will also have higher costs themselves. Hence a total systems approach is needed to find the lowest overall costs.

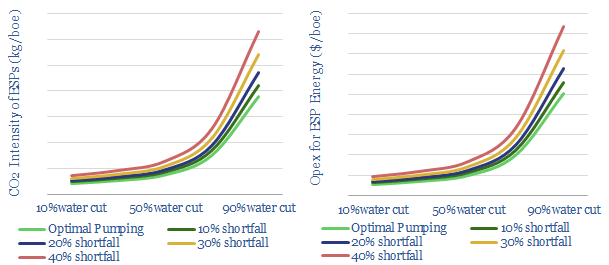

Electric submersible pumps in the oil and gas industry are also modelled in two further back-up tabs. A typical Electric Submersible Pump (ESP) will contribute $0.3/boe of cost and 5kg/boe of carbon, if powered by diesel, at a typical oilfield (chart below). And more at deeper wells with higher water cuts. Switching the ESP to run on renewable power, can readily reduce costs and CO2 intensity.

Please download the data-file to stress test the costs of electric pumps, as a function of lifetime (years), capex costs ($/kW), capital costs (%WACC), utilization rate (%), efficiency (%), flow rates (m3/hour) and other operating costs ($/kW/year).