The Sabatier process combines CO2 and hydrogen to yield synthetic natural gas using a nickel catalyst at 300-400˚C. Synthetic natural gas costs $100/mcf in order to generate a 10% IRR, energy penalties exceed 75% and CO2 abatement cost is $2,000/ton?

Synthetic natural gas could be a green hydrogen carrier in the vicinity of gas pipelines and LNG value chains? Or it could be modified to increase the yields of methane in biogas, which typically contains 30-40% CO2 in the mix?

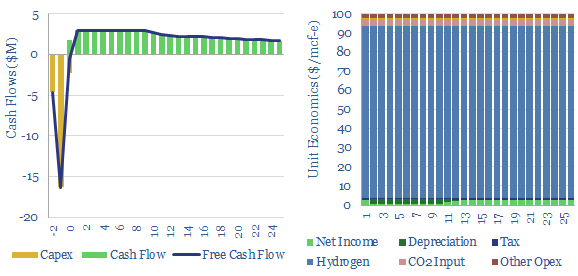

However we think costs will be very high. Our base case economics require a gas price of $100/mcf to earn a 10% IRR, off of capex costs in the range of $1,100/Tpa, slightly higher than a LNG plant but lower than a petrochemicals plant (models here).

Costs are 90% dominated by green hydrogen input costs, which we have penciled in at $7.5/kg, in line with other green hydrogen electrolyser economics. Another $3/mcf of the cost is from sourcing CO2 from an amine plant, or you could source the CO2 from direct air capture.

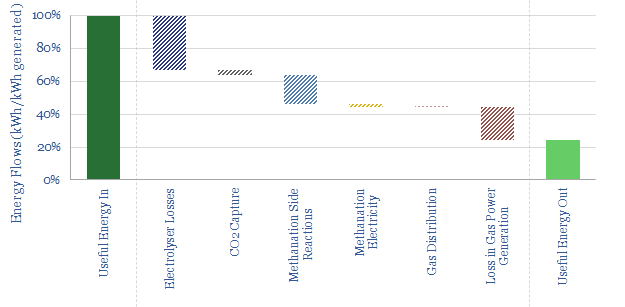

Total energy efficiency is low, most likely below 25%, as we think that an electrolyser will have 65% efficiency producing hydrogen, while there are side-reactions in the methanation plant (forming CO + H2O, C + H2O or C2H6 + H2O).

This data-file allows for some approximate stress-testing of the Sabatier process economics and synthetic natural gas costs. We think there may be some niche uses of power-to-gas or power-to-liquids technologies, but other decarbonization technologies may prove to be more economical and practical in our own roadmap to net zero.