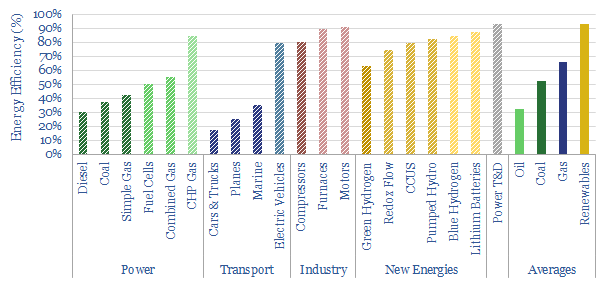

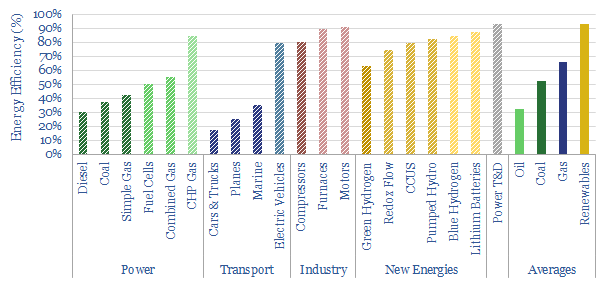

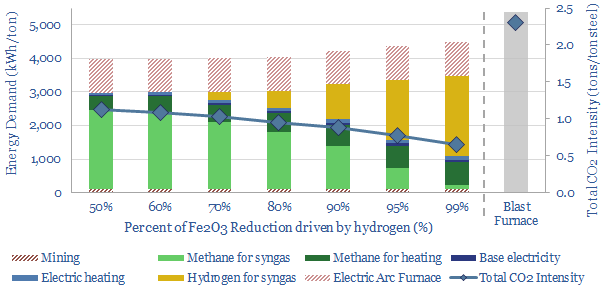

…contrasting the energy efficiency of different processes. $229.00 – Purchase Checkout Added to cart Electrification increases efficiency, at the process level. This is a general theme across analysis of transport, industry and…

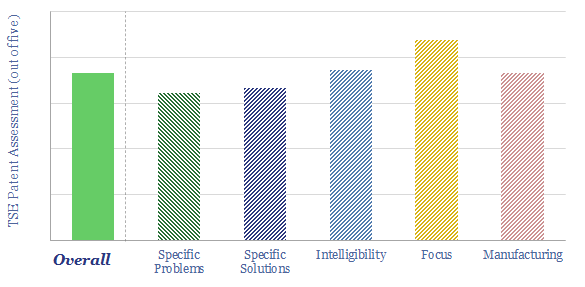

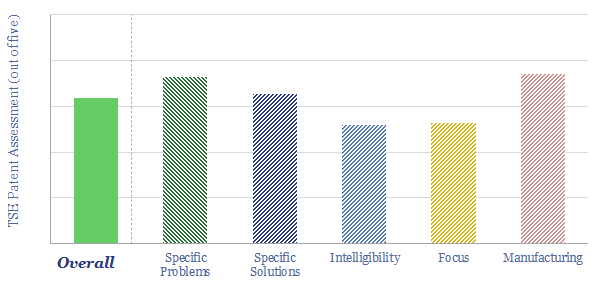

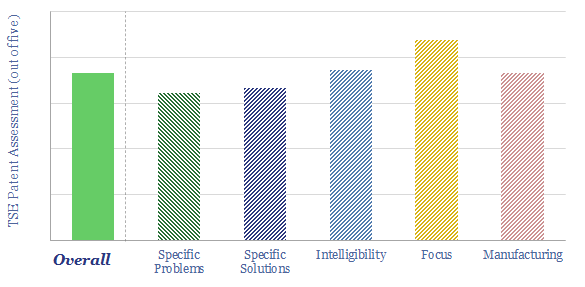

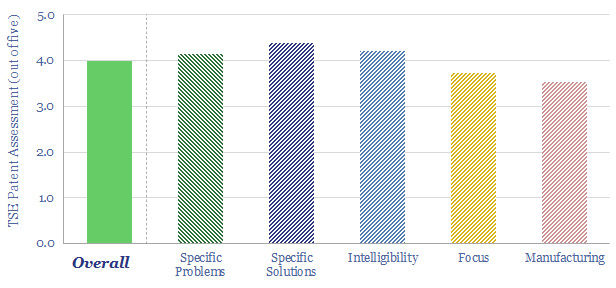

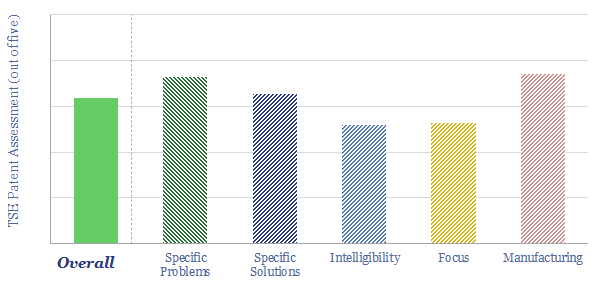

…has c300 employees at the time of writing. By 2022, the company has delivered 2.5 GWH of storage projects. Our Powin technology review finds a moat around specific process improvements…

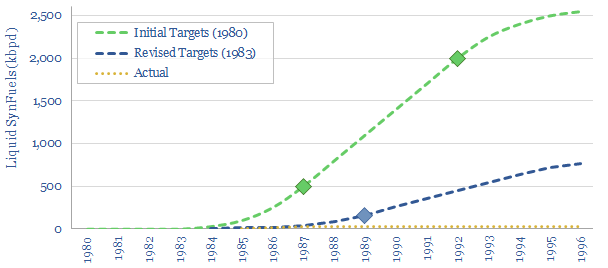

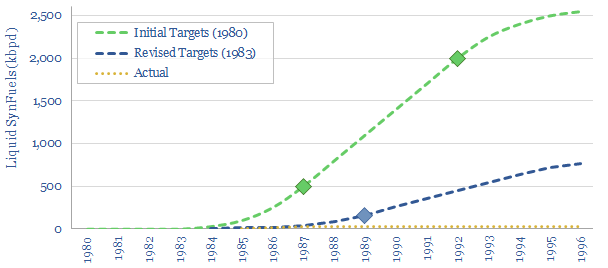

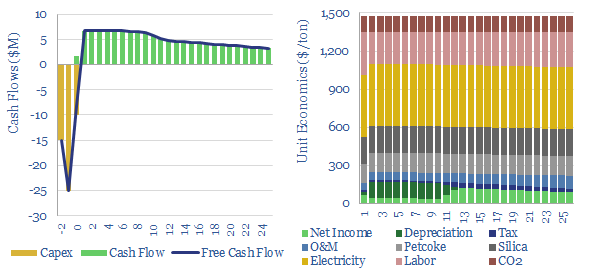

…intermediate, and then converted syngas into liquid fuels. The process is described in more detail on page 5. Costs are a challenge. We have modelled the energy costs of synfuels,…

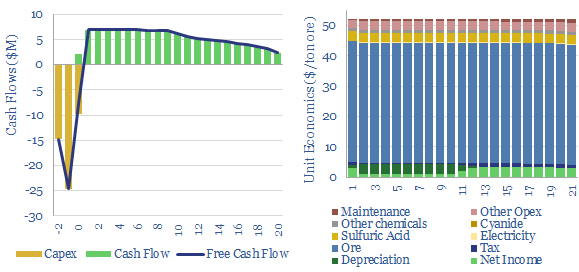

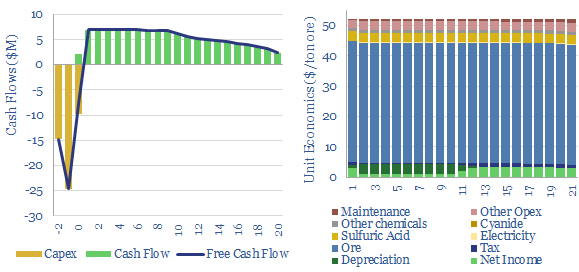

…below). This leach solution is then accumulated for further processing, for example, by electrowinning. The typical costs of heap leaching with H2SO4 might contribute $2.5/kg to the costs of processing…

…and the need for co-reagents. There could be variants of the process that are as expensive and CO2-intensive as conventional copper smelting. Data are tabulated and discussed in the data-file….

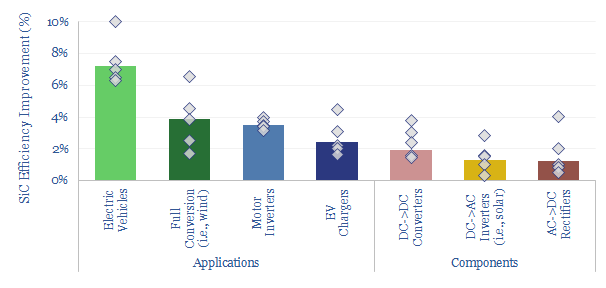

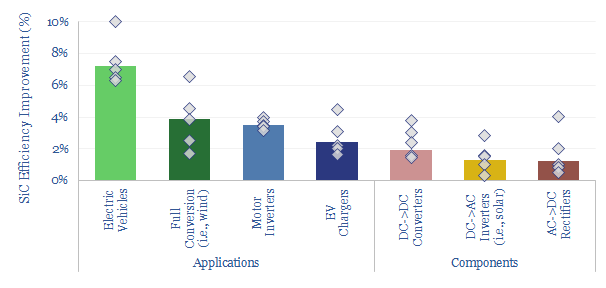

…challenges for SiC, around cost, reliability and scaling. These stem from the production process and can be quantified. Interestingly, we think this set of challenges shapes who is likely to…

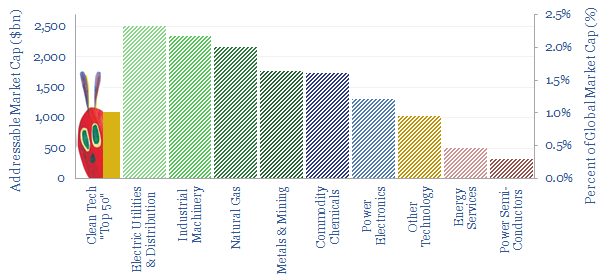

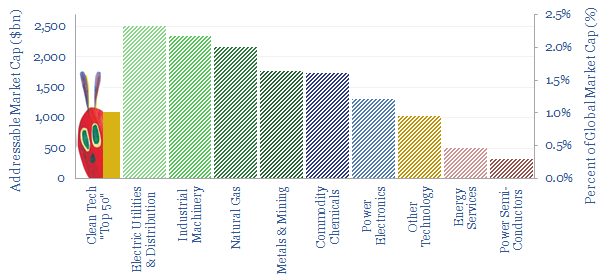

…human history. Commodity chemicals companies that have stood out in our research are noted on pages 8-9. Consuming the energy sector. Building out new energies is a boot-strapping process, pulling…

…Verbio’s EBITDA has recently come from bio-ethanol and bio-methane. And we found the patents here particularly interesting and high-quality. Verbio is using a cold-mash process, which results in 80% lower…

…economic model we have ever constructed. What underpins the exceptionally high costs is that forming SiC crystals from vaporized and highly purified SiC via the Lely Process at 2,000ºC proceeds…

…process reduces the CO2 intensity of a value chain, usually by over 50%, often over 90%, by pairing it with some form of CCS (page 2). Most famous are blue…