Search results for: “direct air capture”

-

Geothermal energy: costs and economics?

Geothermal energy costs are modelled from first principles in this data-file. LCOEs of 6c/kWh are available in geothermal hotspots. Outside of the hotspots, enhanced geothermal heat can cost 2-14c/kWh-th for a 10% IRR on $500-5,000/kW-th capex, while a rule of thumb is that geothermal electricity costs 5x geothermal heat.

-

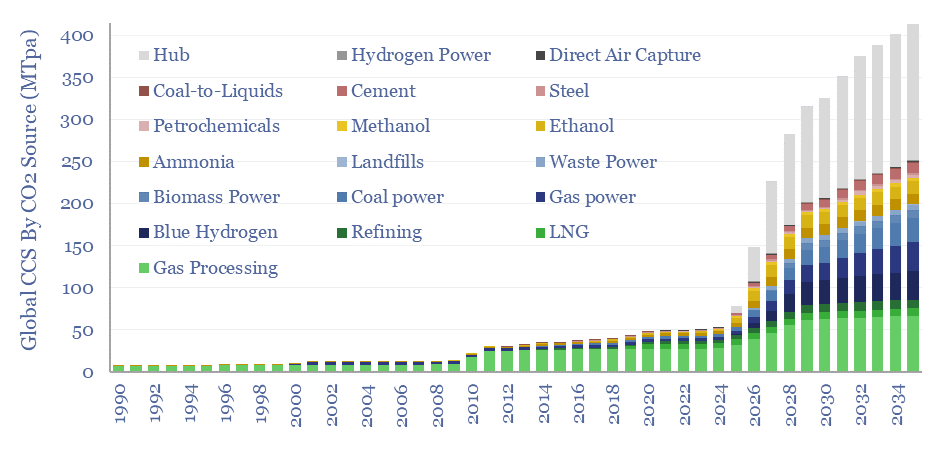

Global CCS Projects Database

Over 400 CCS projects are tracked in our global CCS projects database. The average project is 2MTpa in size, with capex of $600/Tpa, underpinning over 400MTpa of risked global CCS by 2035, up 10x from 2019 levels. The largest CO2 sources are hubs, gas processing, blue hydrogen, gas power and coal power. The most active…

-

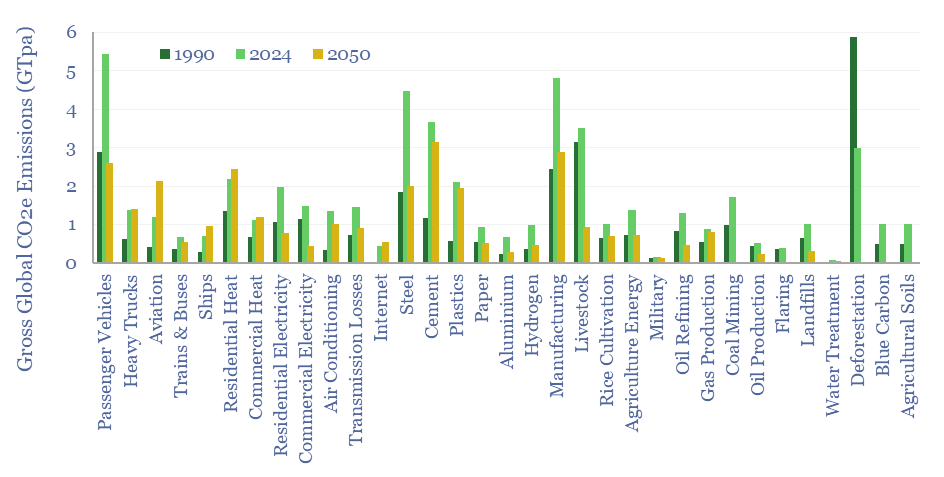

Global CO2 emissions breakdown?

Global CO2 emissions rose from 32GTpa of CO2-equivalents in 1990 to 54GTpa in 2024, and are seen optimistically declining to 30GTpa by 2050, on a gross basis. This global CO2 emisisons breakdown covers 33 sources that each explain over 0.5% of global CO2e emissions, as a way of tracking emissions by source, by year, and…

-

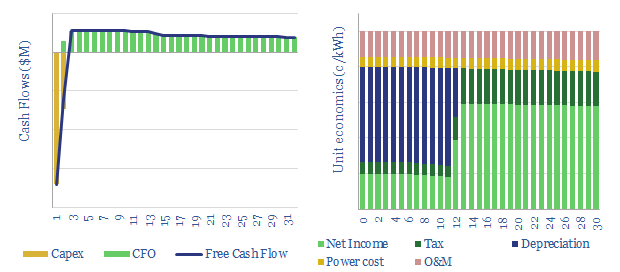

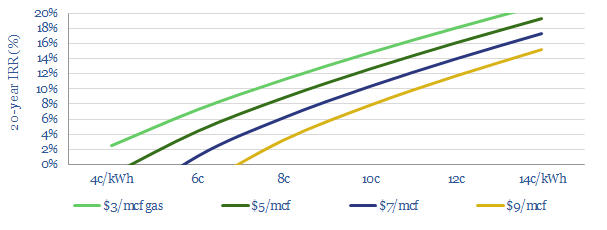

Oxycombustion: economics of zero-carbon gas?

Oxy-combustion is a next-generation power technology, burning fossil fuels in an inert atmosphere of CO2 and oxygen. It is easy to sequester CO2 from its exhaust gases, helping heat and power to decarbonise. We argue that IRRs can be competitive with conventional gas-fired power plants.

-

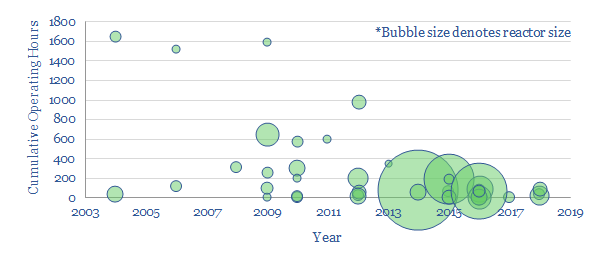

Chemical Looping Progress?

Chemical Looping Combustion could clean up future coal or gas-fired power. But will it work? We have tabulated data from the technical literature on 40 chemical looping combustion pilots. They have run collectively for 10,000 hours. They promise 38% energy efficiencies for zero carbon emissions.

-

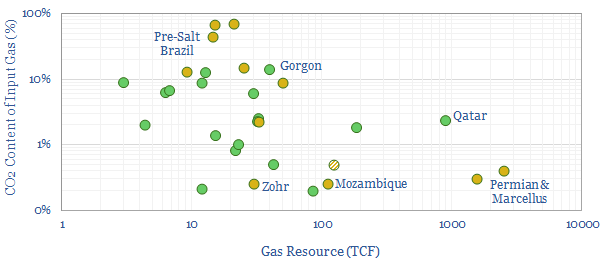

The World’s Great Gas Fields and Their CO2

This data-file tabulates 30 major gas resources around the world, their volumes, their CO2 content and how the CO2 is handled. This matters because higher CO2 gas fields are more costly to develop into LNG, while CO2 venting is no longer acceptable without CCS. Permian & Marcellus LNG are best positioned.

-

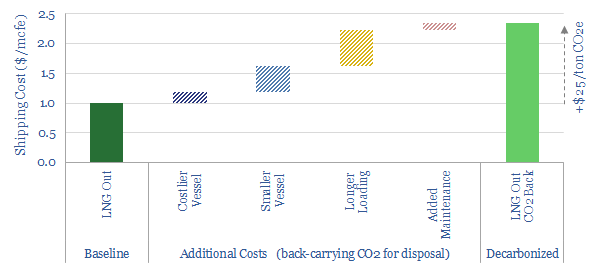

Decarbonized gas: ship LNG out, take CO2 back?

This note explores an option to decarbonize global LNG: (i) capture the CO2 from combusting natural gas (ii) liquefy it, including heat exchange with the LNG regas stream, then (iii) then send the liquid CO2 back for disposal in the return journey of the LNG tanker. There are some logistical headaches, but no technical show-stoppers.…

-

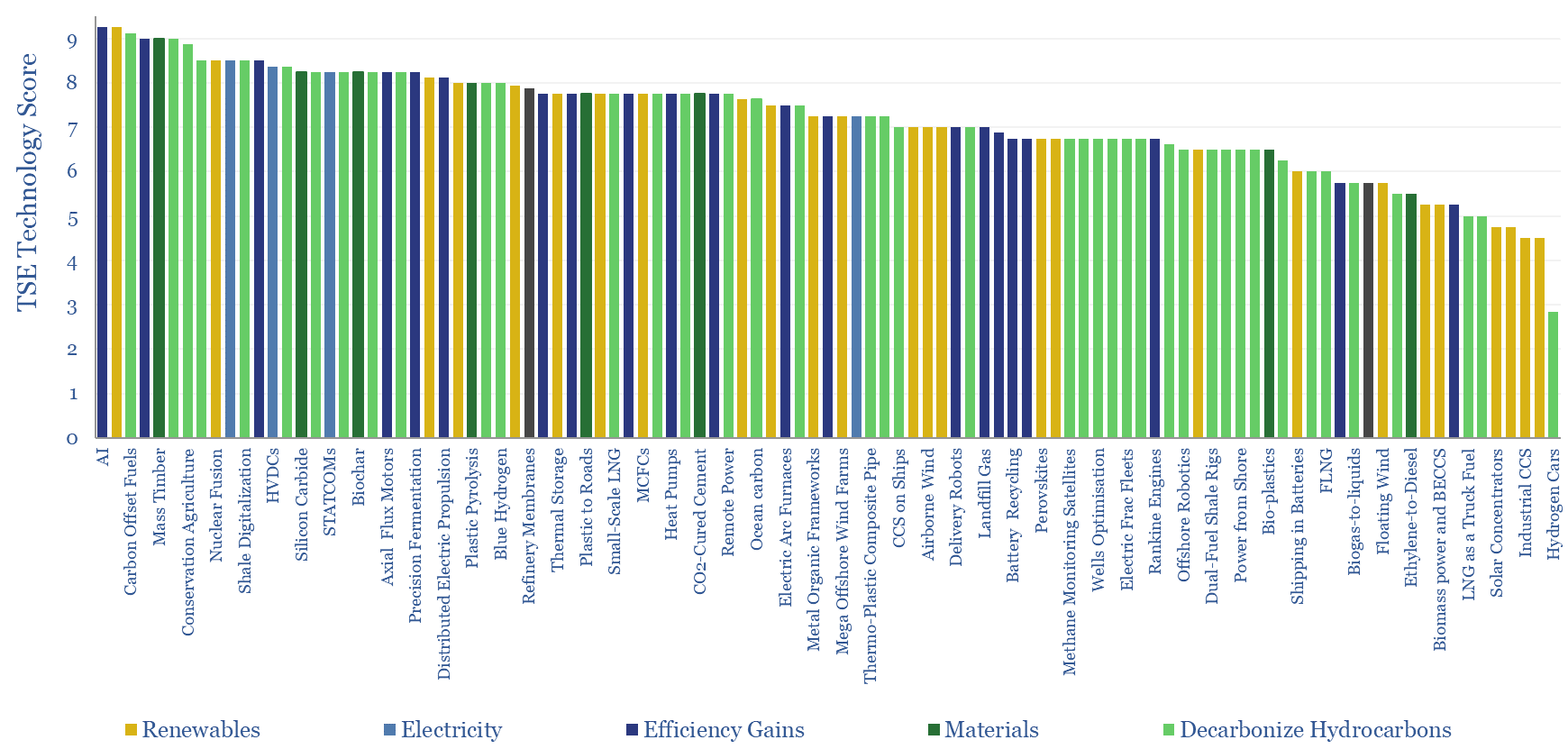

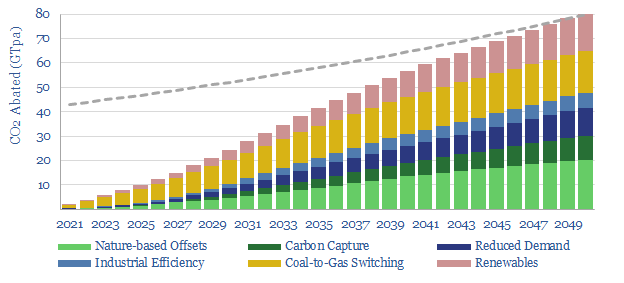

Decarbonizing global energy: the route to net zero?

The global energy system can be fully decarbonized by 2050, for an average CO2 cost of $42/ton. Remarkably, this is almost half the cost foreseen one year ago. 85Mbpd of oil and 375TCF pa of gas are still required in this 2050 energy system, together with efficiency technologies, carbon capture and offsets.

-

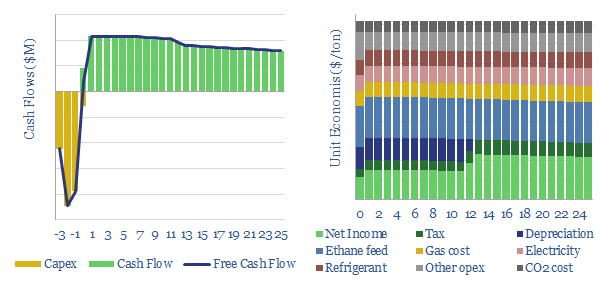

Ethane cracking: the economics?

This data-file captures the economics of ethane-cracking to produce ethylene. A typical US Gulf Coast facility could generate 15% IRRs at typical capex cost of $1,135/Tpa. CO2 intensity can be as high as 1.7T of CO2 per ton of ethylene, or potentially much lower depending on the facility’s energy efficiency.

Content by Category

- Batteries (89)

- Biofuels (44)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (95)

- Data Models (840)

- Decarbonization (160)

- Demand (110)

- Digital (60)

- Downstream (44)

- Economic Model (205)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (279)

- LNG (48)

- Materials (82)

- Metals (80)

- Midstream (43)

- Natural Gas (149)

- Nature (76)

- Nuclear (23)

- Oil (164)

- Patents (38)

- Plastics (44)

- Power Grids (130)

- Renewables (149)

- Screen (117)

- Semiconductors (32)

- Shale (51)

- Solar (68)

- Supply-Demand (45)

- Vehicles (90)

- Wind (44)

- Written Research (355)