Jetti Resources has developed a breakthrough technology to recover copper from low-grade sulfide ores, by leaching with sulphuric acid, thiocarbonyls, ferric iron (III) sulphates and oxidizing bacteria. The patents lock up the technology, presenting some of the most detailed experimental data of any patent library that has crossed our screen. But what are the costs of copper production, what CO2 intensity and what technical challenges remain?

Jetti Resources was founded in 2014, it is headquartered in Boulder, Colorado, and employs c50 people. It aims to “unlock, vast stranded copper resources” via a breakthrough technology. This matters as our roadmap to net zero sees global copper demand rising 3x by 2050.

The company has raised $100M via a Series D financing round in October-2022, valuing Jetti at $2.5bn. Its technology is being used in two commercial deployments, including Capstone Copper’s Pinto Valley Mine in Arizona.

The technology extracts copper from low-grade sulfides, which make up 70% of the world’s copper resources, worth $20trn, such as chalcopyrite, the most common copper mineral ore.

However, these challenging ores are currently stranded. The copper cannot be leached out using sulphuric acid and then electrowon; as a passivation layer forms on the surface of sulfide ores. And the financial and environmental costs of transporting these ores to Asian smelters are also high.

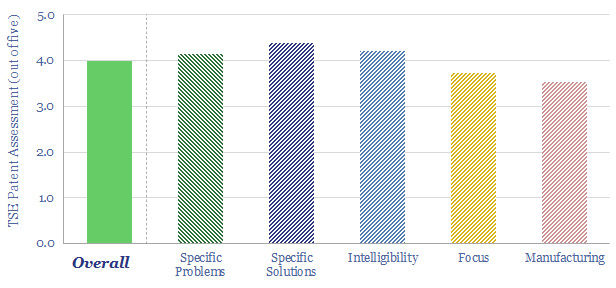

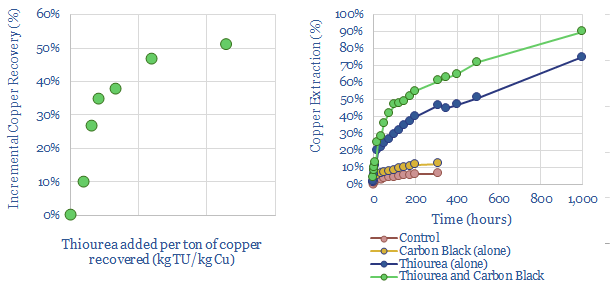

We have reviewed Jetti Resources’ technology. Its patent library is concentrated, with two particularly clear patents, containing some of the most detailed experimental data that has crossed our screens in all of our patent reviews (the chart below shows how thiourea, and other reagents, enhances copper recovery). We can partly de-risk the technology based on our patent review. It does seem like a technical breakthrough.

Some variants in the patents also show a complementary benefit combining thiocarbonyls with carbon black, which raises the intriguing possibility of providing an offtake for the carbon black coming out of turquoise hydrogen plants.

There are four major challenges to explore, based on our Jetti Resources technology review. They include thiocarbonyl pricing (and resultant copper pricing), thiocarbonyl quantities needed (i.e., kg of thiourea per kg of copper recovery), environmental credentials and the need for co-reagents. There could be variants of the process that are as expensive and CO2-intensive as conventional copper smelting. Data are tabulated and discussed in the data-file.