Can we de-risk Air Products’s ammonia cracking technology in our roadmaps to net zero, which is crucial to recovering green hydrogen in regions that import green ammonia from projects such as Saudi Arabia’s NEOM. We find strong IP in Air Products’s patents. However, we still see 15-35% energy penalties and $2-3/kg of costs in ammonia cracking.

Air Products is an industrial gas giant, listed in the US, with 23,000 employees, producing atmospheric gases, operating 100 hydrogen plants with 3bcfd of capacity and a 600-mile pipeline network on the Gulf Coast, helium and LNG process technologies. It is expanding into blue hydrogen and green hydrogen + hydrogen transport.

The NEOM Green Hydrogen project in Saudi Arabia aims to export 1.2MTpa of green ammonia, derived from 220kTpa of green hydrogen, in turn derived from 4GW of wind and solar, with total capex of $8.4bn.

However, the part of the hydrogen->ammonia->hydrogen value chain that has seemed most challenging to us is in cracking ammonia back into hydrogen. The key challenges for ammonia cracking are energy intensity, costs, longevity and impurities.

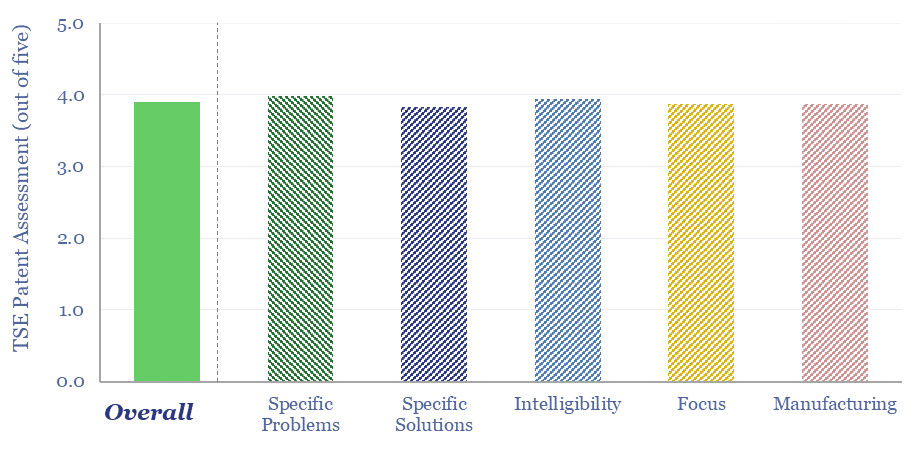

Hence in this data-file, we have assessed Air Products’s ammonia cracking technology. The patents are high-quality: clear, specific, intelligible, focused and manufacturable. Hence we think Air Products has invested material time and effort in optimizing the ammonia cracking process, and has built a moat around its technology.

Specific details in the data-file focus on catalyst compositions (patented), heat recapture (patented), ammonia recirculation (patented), product purification (patented), breaking down impurities (patented), avoiding various impurities, avoiding nitriding (patented), and integration with hydrogen fueling stations (patented).

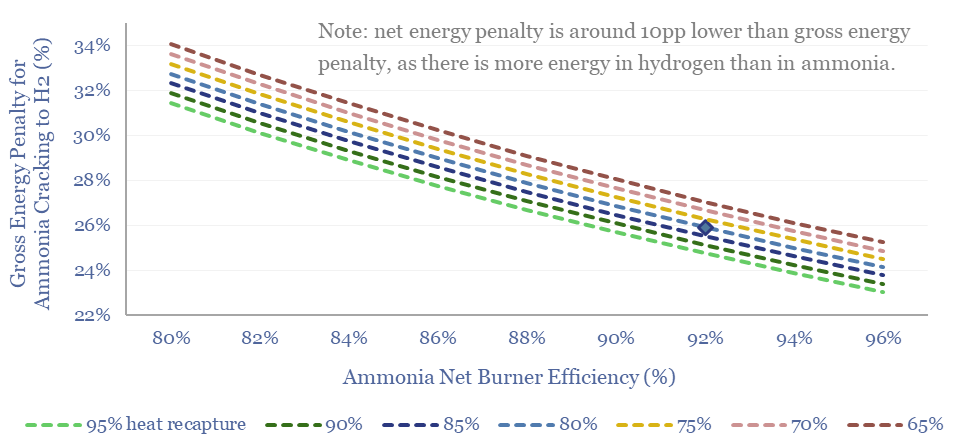

But overall, the details in the patents also remind us how complex the process of ammonia cracking back into hydrogen really is. We estimate gross energy penalties equivalent to using up around 25% of the ammonia that is imported, and net energy penalties of 15% (after reflecting the higher energy content of hydrogen versus ammonia).

The costs of cracking ammonia into fuel-cell grade green hydrogen are modeled in the range of $2-3/kg, both in this model, and in our model of hydrogen transportation.