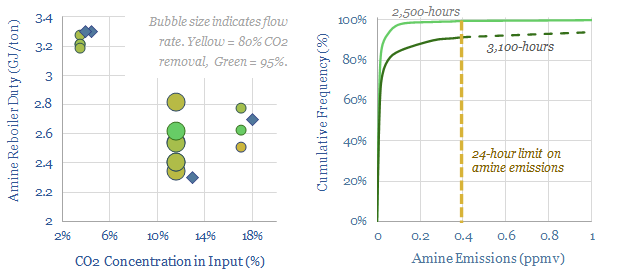

…lab studies under-estimate degradation rates, amine make-up processes will dent utilization, other operational parameters degrade alongside the amines, degraded amines corrode amine plants and equipment, they can result in toxic…

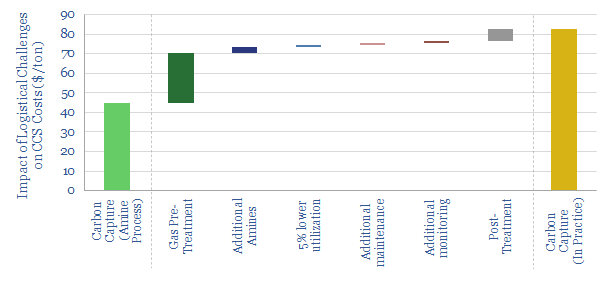

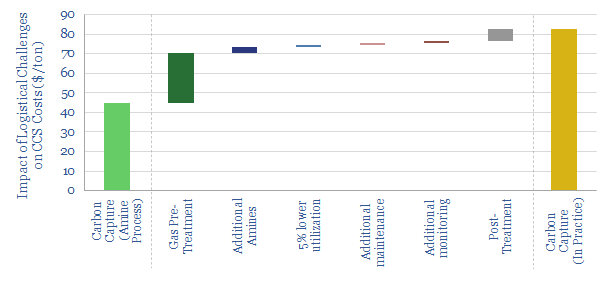

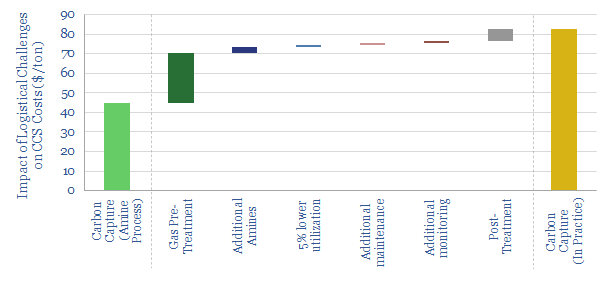

Post-combustion CCS has more practical challenges than we had previously assumed, which are explored in this 13-page report. Today’s established amines require extensive pre- and post-treatment of gases; to prevent…

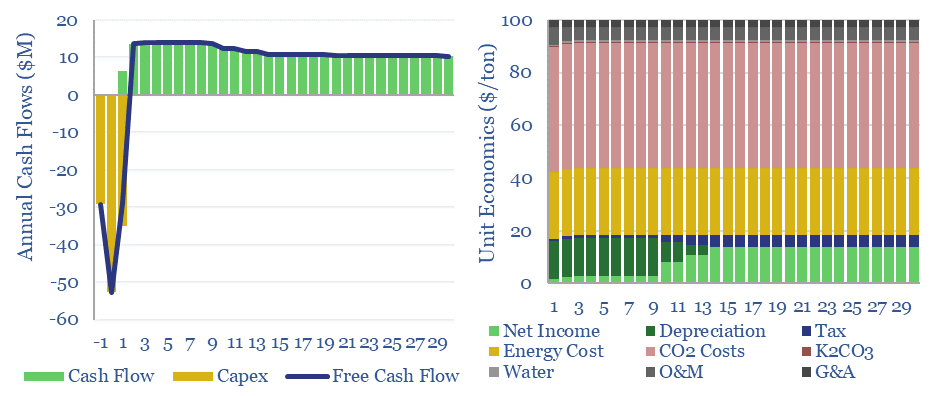

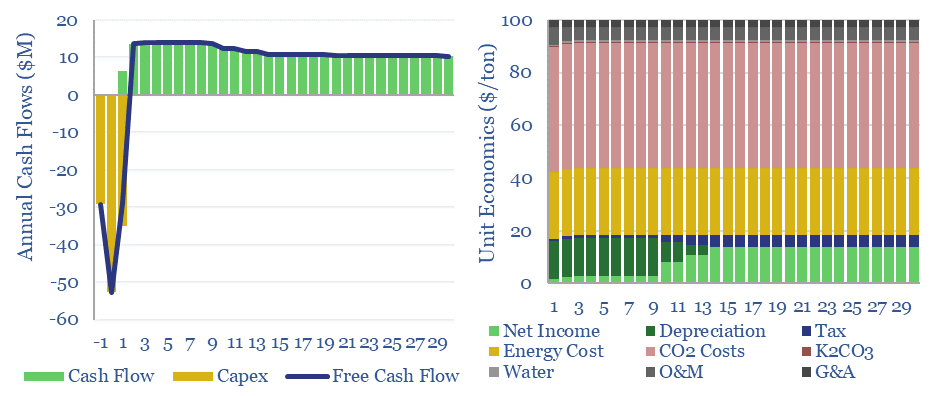

…column of lean amines, which react with CO2 to form rich amines. The CO2 can later be re-released and concentrated by steam-treating the amines in a regenerator. Base case costs…

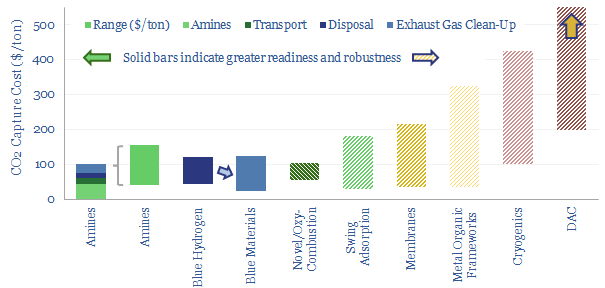

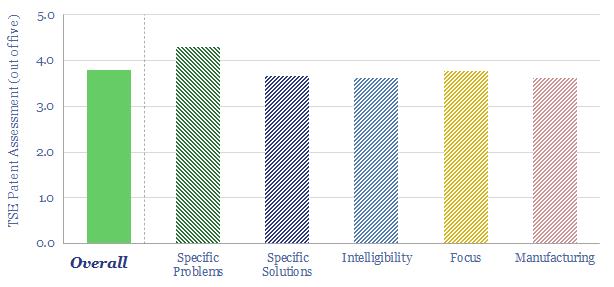

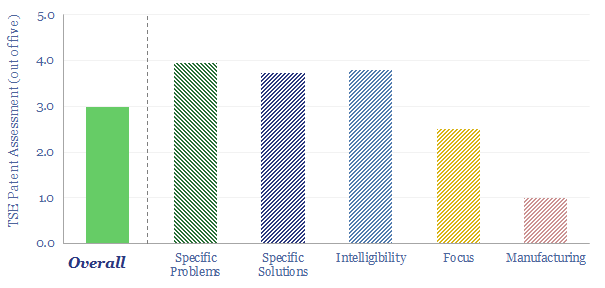

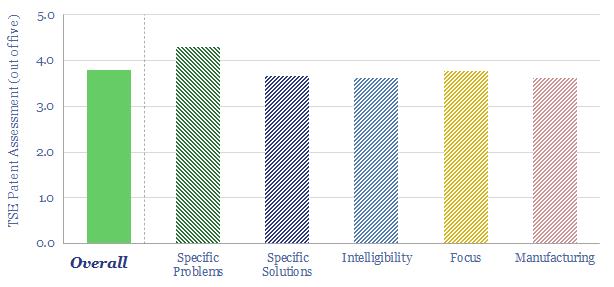

…data. This can be compared with other amines here. Economics of post-combustion CCS using amines can be stress-tested here. Underlying data and further notes are in the data-file. So far,…

…to air, including for ammonia, amines, but especially for toxic/carcinogenic breakdown products, such as nitrosamines, which ideally will not be generated at all; and (e) have low corrosiveness. To address…

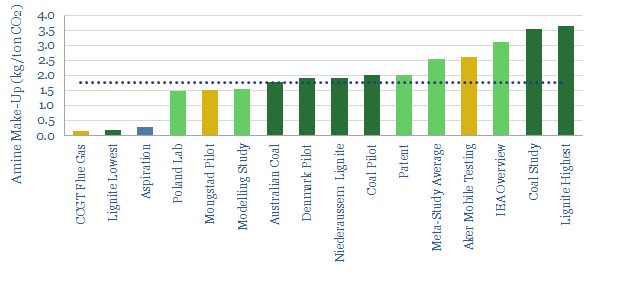

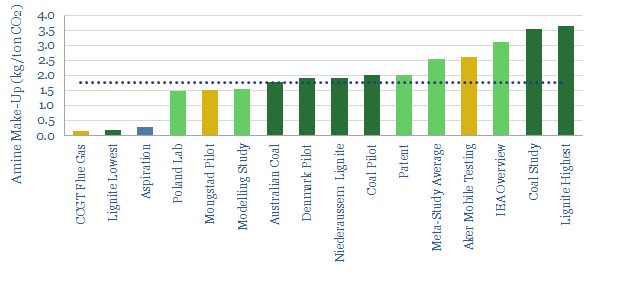

In post-combustion CCS facilities, amines react with CO2, which can later be re-released via steam-treating, and sent for sequestration. However, CCS plants have amine make-up rates, to replace amines that…

…with amines (often piperazine). But this seems to defeat the rationale for using potassium carbonate in the first place, which was to avoid emissions of amines or their toxic breakdown…

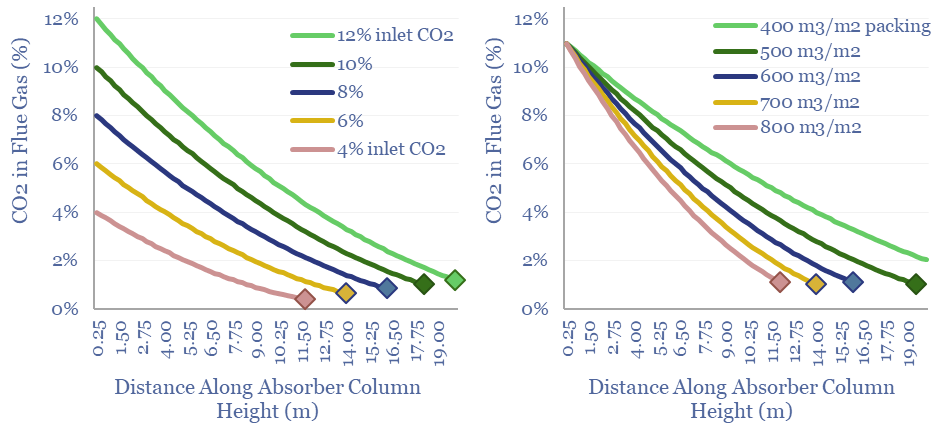

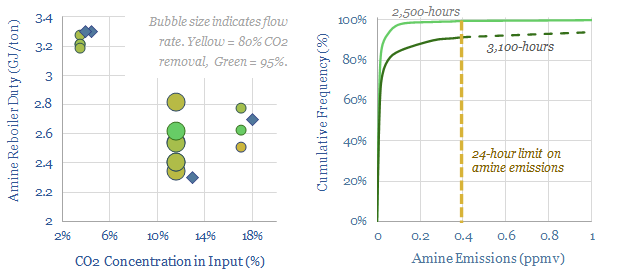

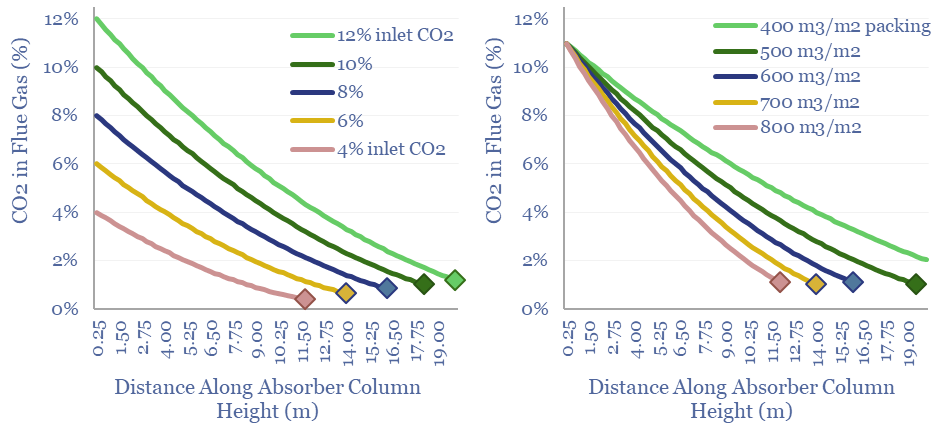

Post-combustion CCS plants flow CO2 into an absorber unit, where it will react with a solvent, usually a cocktail of amines. This data-file quantifies operating parameters for CCS absorbers, such…

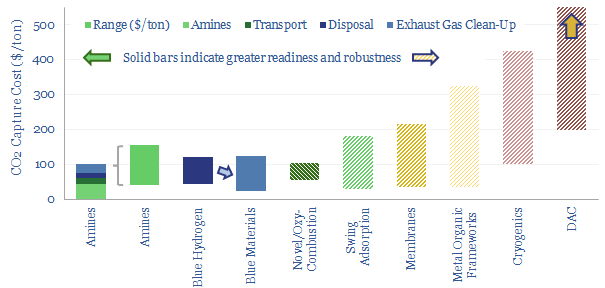

…to separate CO2 (4-40% concentration) from air (mostly nitrogen). Amines can do this, but the process is costly, energy intensive and amines can be degraded by contaminants. Oxy-combustion is an…

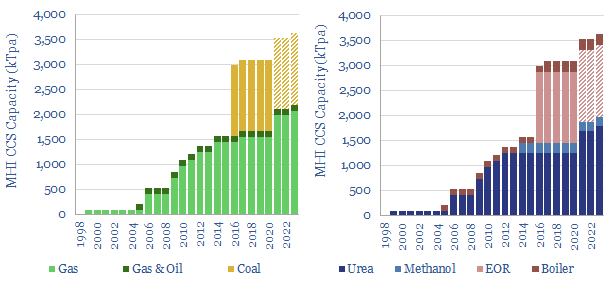

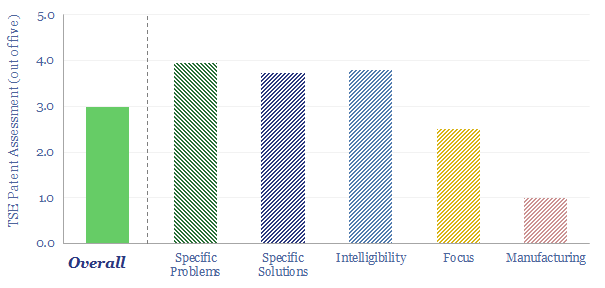

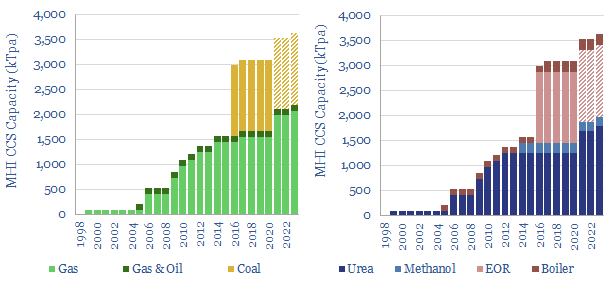

…next-generation amines to beat. This data-file aggregates notes and datapoints into MHI CCS technology. $299.00 – Purchase Checkout Added to cart KM-CDR is the Kansai Mitsubishi Carbon Dioxide Recovery Process, honed over…