Absorption chillers perform the thermodynamic alchemy of converting waste heat into coolness. Capex costs of absorption chillers average $600/kW-th and all-in absorption chiller costs run to 6-7 cents/ton-hour, depending on the price of incoming waste heat. This data-file captures the economics of absorption chillers from first principles.

Absorption chillers perform the thermodynamic alchemy of converting waste heat into coolness, using an evaporator, absorber, generator and condenser, and as explained in our recent research note into absorption chiller cool concepts.

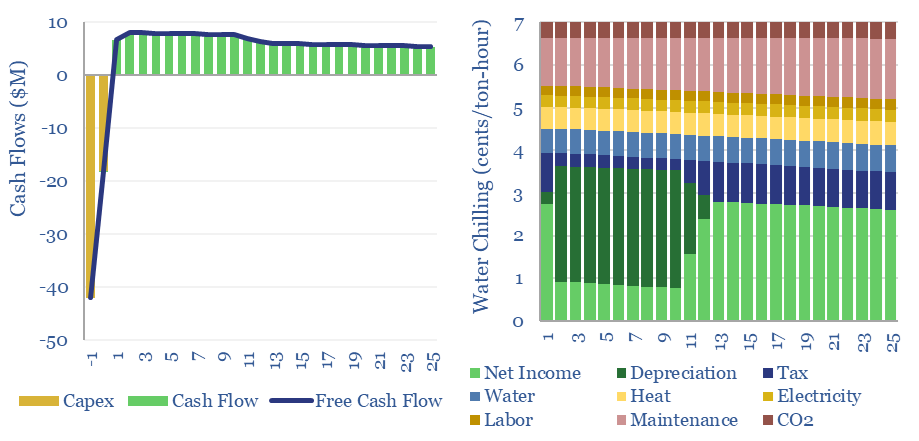

This data-file captures absorption chiller costs, across capex, opex, heat use, electricity use, maintenance, CO2 emissions and in order to generate economic IRRs.

Our numbers are informed by patents and technical papers into absorption chillers, which are summarized on the final 2-3 tabs of the model.

Data-points in these patents and technical papers show how Coefficient of Performance (CoP) can range from 0.6 to 1.4x (i.e., each kWh-th of incoming heat can be used to generate 0.6-1.4 kWh-th of cooling).

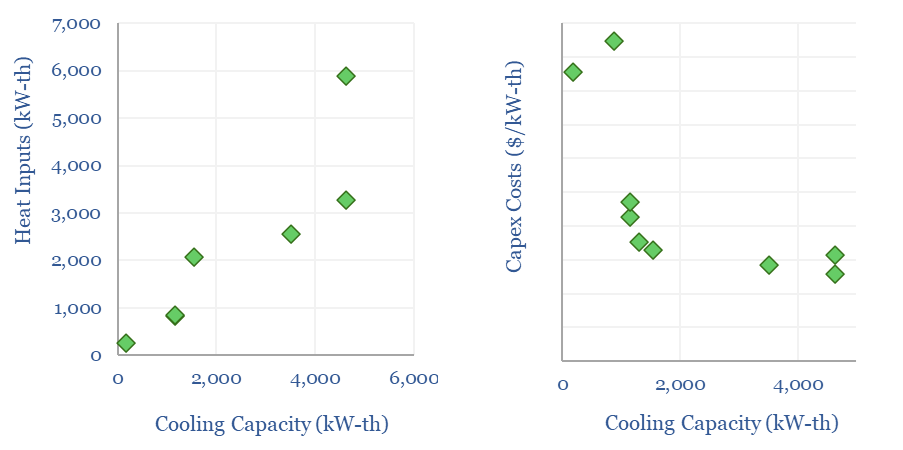

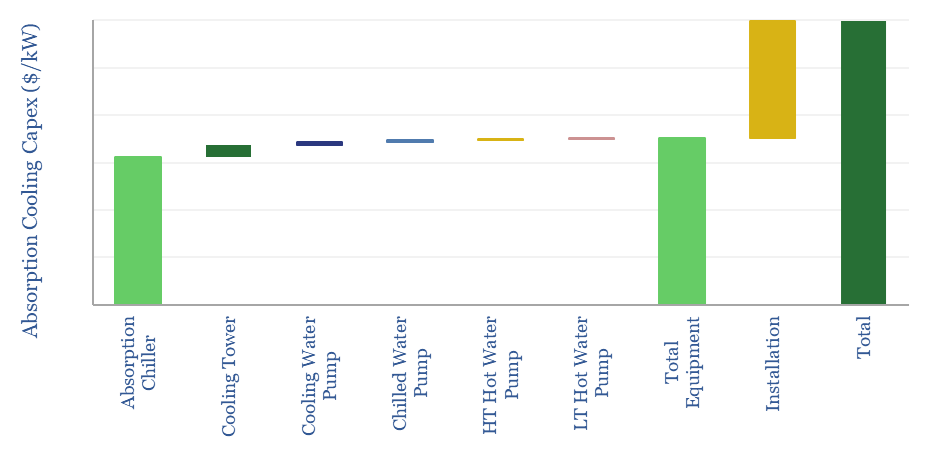

Likewise, capex costs of absorption chillers might typically run to $600/kW-th, although this does depend on the size and configuration of the system (e.g., single stage, dual stage, and the absorber-refrigerant pair, such as LiBr-water, or water-ammonia).

Many studies show 50-90% electricity use after installing absorption chillers.

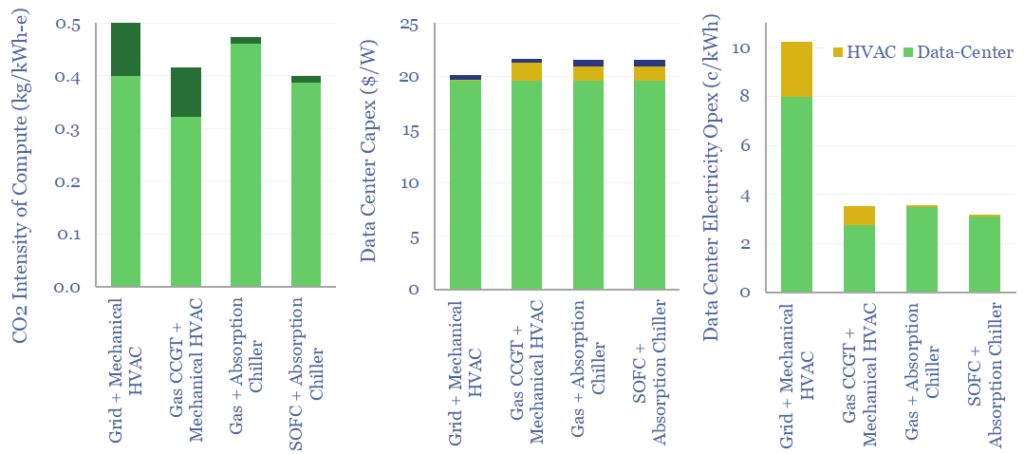

It is particularly interesting to explore the costs of data centers, and the costs of cooling data centers, contrasting the use of mechanical HVAC versus absorption chillers. Numbers in this model show low total system costs when capturing the waste heat from solid oxide fuel cells to drive absorption chillers.

Water-LiBr absorption coolers are most commonly used today, however another variant uses ammonia as the refrigerant and water as the absorbent. One advantage is that ammonia’s boiling point at 1 atm of pressure is -33ºC, hence these systems can get down to lower temperatures, and without having to run under an extreme vacuum.

Absorption chiller costs can be broken down and stress-tested from first principles in this model.