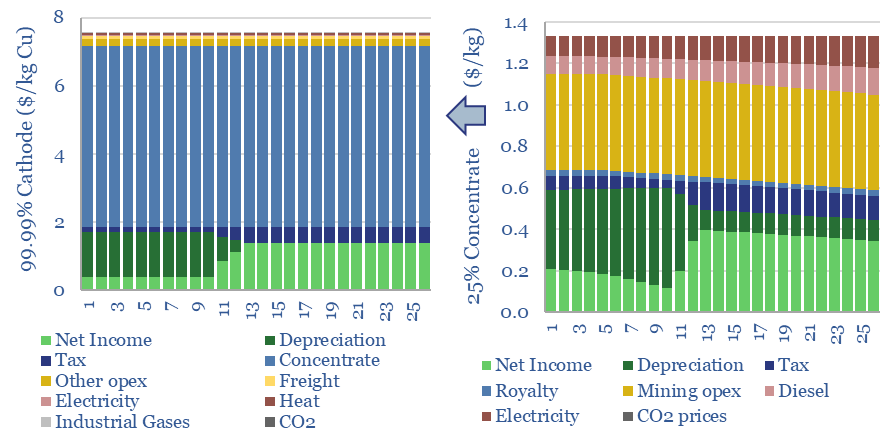

The economic cost of copper production is built up from first principles in this model, from mine, to concentrator, to smelter to 99.99% pure copper cathodes. Our base case is $7.5/kg copper cathode, with 4 tons/ton CO2 intensity, after starting from an 0.57% ore grade. Numbers vary sharply and can be stress-tested in the data-file.

70-80% of all primary copper is produced by the smelting route and mainly starting with sulphide ores. First, ore is mined, moved, crushed and concentrated to around 20-40% purity. The ‘CopperOreMine’ tab of the model captures the costs, energy use and CO2.

Further downstream, the ores may be roasted to change their crystal structure before smelting, smelted in an environment of enriched oxygen to reject sulfur as sellable sulphuric acid, yielding matte with c50-70% purity.

Even further downstream, matte is upgraded to blister with c99% purity, which is melted and cast into anodes for electrochemical refining, yielding copper cathodes with 99.99% purity. Copper cathode is one of the most traded metals on Earth, underpinning the LME copper contract, as pure copper is purchased and processed into semis, wires and cables.

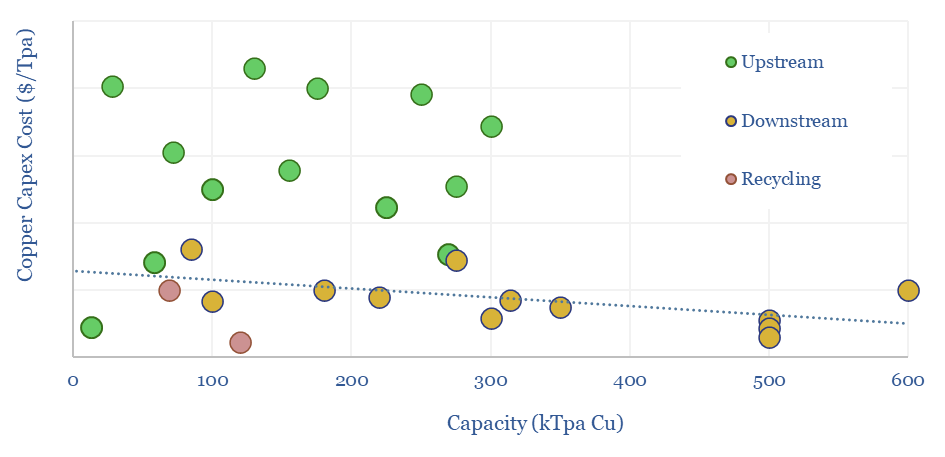

The economic cost of copper production is built up from first principles in this model, from mine, to concentrator, to smelter to 99.99% pure copper cathodes. Our base case is $7.5/kg copper cathode, with 4 tons/ton CO2 intensity. Capex intensity of copper is plotted below in $/Tpa.

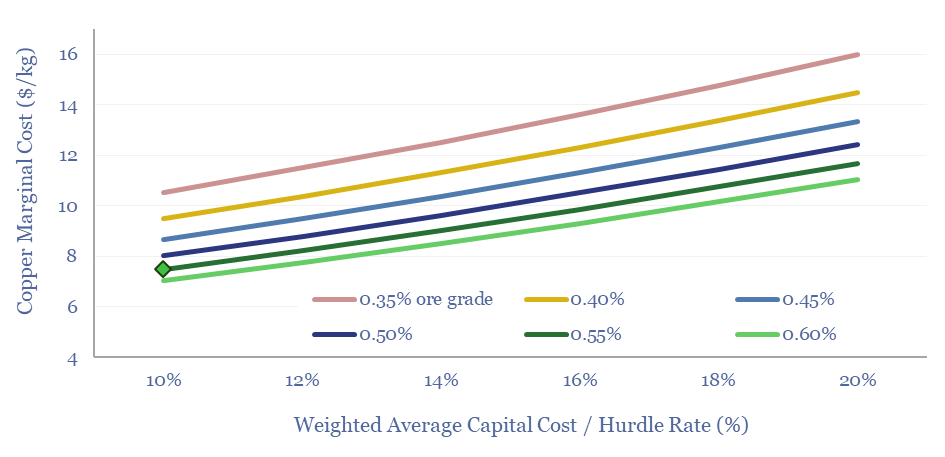

But the costs of copper production depend heavily on ore grade and mining/refining technology. We estimate that a 0.1% reduction in future copper ore grading increases marginal cost by around 10% and CO2 intensity by around 10%, which matters as copper demand is set to treble in the energy transition.

Moreover, each $100/ton of CO2 prices would increase marginal cost by another 5%. It is not unimaginable that copper prices could reach $15,000/ton in an aggressive energy transition scenario, if you stress-test the model.

There is no silver bullet to decarbonize primary copper production, because of the large number of processing steps described above and in the data-file. Hence the best option to decarbonize copper production are to increase the reliance on secondary production (i.e., recycling, e.g., Aurubis).

The best option to decarbonize primary copper, based on stress testing our models, is to use clean electricity for processes such as crushing and flotation, which can save over 1 ton/ton of CO2. Using these processes flexibly can potentially even help to integrate renewables. Finally, we think that electrochemical production, e.g., via solvent extraction then electrowinning (the favored route for oxide ores that cannot be floated), can reduce total CO2 intensity by a further 1 tons/ton when using clean electricity.