Mining: crushing-grinding costs. Extracting useful resources from mined ores requires comminution. This is the integrated sequence of crushing and grinding operations, which breaks down mined rubble (3-10 cm diameter), effectively into talcum powder (30-100µm), which can in turn enter the metal refining process with sufficient surface area to extract the valuable materials.

The purpose of this data-file is to tabulate typical cost estimates for crushing-grinding processes, which consume 1-2% of all the energy in the world and 20-50% of the energy in some mining processes. Our numbers are shown per ton of ore, so clearly lower ore grades translate into higher costs per unit of extracted material (guide here).

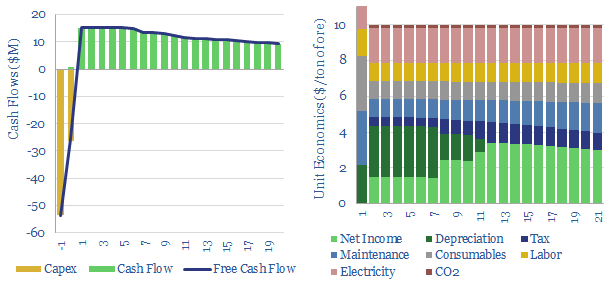

Energy economics. A good rule of thumb is that an integrated mining crushing-grinding plant will have capex costs of $20/Tpa of capacity and consume 20kWh of energy per ton, while total full-cycle costs will run close to $10/ton of ore that is processed. (Numbers can be stress-tested in the ‘model’ tab).

Our capex estimates are informed by evaluating a dozen actual project disclosures and technical papers, spanning across the gold, silver, iron, copper and limestone quarrying industries (see the ‘capex’ tab).

Our energy intensity estimates are informed by mine disclosures and technical papers, but we have also derived our own bottom-up numbers using the Bond Equation. The suggested work index for this model depends on rock hardness, and varies from 9kWh/ton in soft rocks (barites, bauxites, fluorspars, phosphates) through to 13kWh/ton at harder rocks (copper ores, hematites, limestones) and higher again at volcanics (see ‘Bond’ tab).

Interestingly, we also think crusher-grinder units in the mining sector can smooth our volatile power grids by demand shifting.

Please download the data-file to stress-test mining crushing-grinding costs, across capex, opex, maintenance, labor, electricity prices, CO2 prices, uptime & utilization and ore grades.

Our 5 conclusions on the crushing-grinding industry are highlighted in the article sent to our distribution list here.