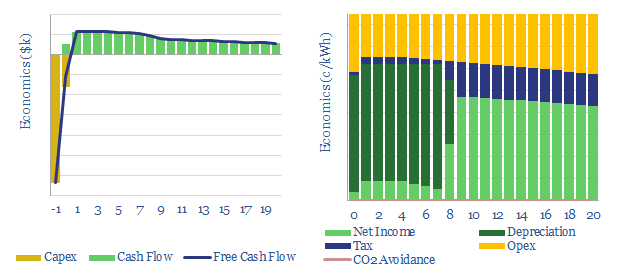

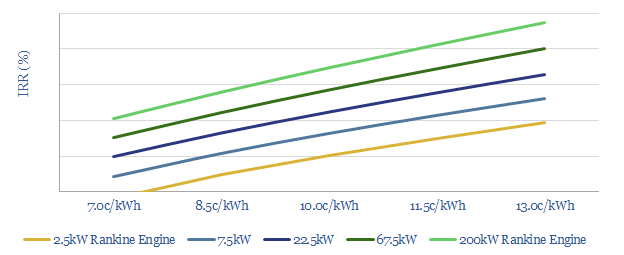

This data-file captures the economics of an Organic Rankine Cycle engine to recover low-grade waste heat (at 70-200ºC) from an industrial facility, or in the geothermal industry. A CO2 price of $50-75/ton could greatly accelerate adoption and improve the efficiency of industrial facilities.

Rankine cycles are a form of thermodynamic heat engine generating mechanical energy by evaporating a liquid into a high-pressure gas, then expanding the gas across a turbine, before re-condensing it. The mechanical energy can be used to drive a generator and produce electricity. The working fluid is usually water, which boils into steam at 100ºC, and then is super-heated to 300-500ºC.

Organic Rankine Cycles aim to harness mechanical energy from lower-temperature heat sources. For example propane boils at -42°C, methanol boils at 65°C and ethanol at 78°C. Past systems have historically also used fluorocarbons.

Organic Rankine Cycles can be useful for waste heat recovery in combination with heat exchangers, or to generate electricity from lower-temperature energy sources such as geothermal. Europe started building ORC plants in the 1980s, and now has 120-150 with multiple megawatts of capacity, often fed by biomass.

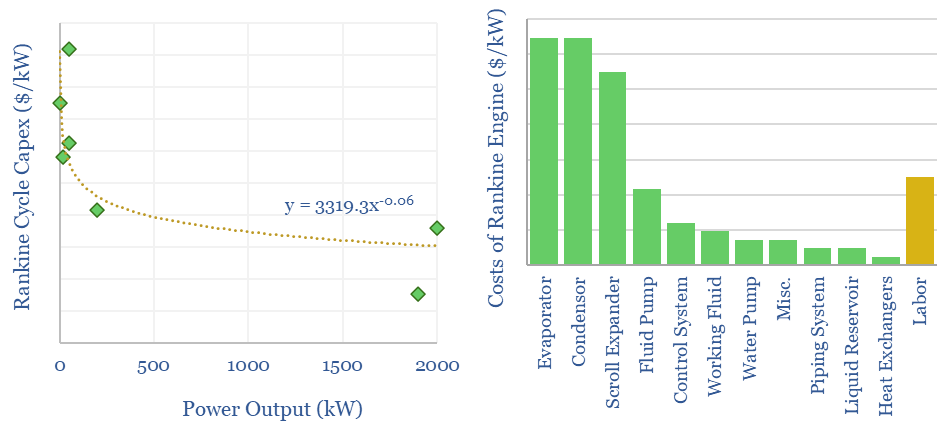

Hence what are the costs of Organic Rankine Cycles? Our model draws on past project data and technical papers to estimate capex (in $/kW), thermal efficiency levels (in %) and the levelized costs of power from Organic Rankine Cycle engines.

Capex costs of Organic Rankine Cycle engines are estimated at around $2,000/kWe, as built up from top-down estimates and bottom-up estimates, in this data-file.

The data show how economics vary with facility size (below) and how large an industrial facility needs to be to be able to install an Organic Rankine Cycle heat recovery system.

Notes on the industry are also tabulated, including how the technology works, total market size, capacity and leading companies ranked by past project deliveries.