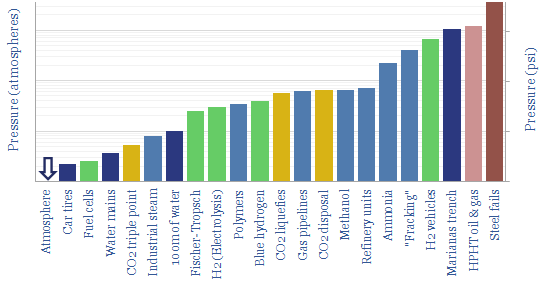

The purpose of this data-file is to chart the typical pressures of industrial processes and energy processes, as a useful reference. We are all used to 1 atmosphere of pressure, which is 1.0125 bar, 0.10125 MPa and 14.7 psi. But what pressures do industrial processes use?

Pressures of industrial processes range from 1 atmosphere to around 4,000 atmospheres (at which point structural steel fails, per our overview of materials properties).

We all have experience with 1 atmosphere of pressure (1 bar), simply by existing in the world. A car tire is at 2-bar, which is about the same as the water pressure if you dive to a depth of 10 meters. But industrial pressures tend to be higher.

For example, moderate pressures of about 60-bar are routinely used in gas pipelines, methanol plants and in the cryogenic turbine compressors feeding cryogenic air separation plants or LNG plants.

Higher pressure industrial processes will reach around 200-bar, for example in the turbine inlet temperature of a gas turbine, or in an ammonia plant.

One conclusion is that conventional energy and chemical companies have good pre-existing experience with engineering and managing pressure-vessels, and raising gases to high pressures using compressors. But is the need for compression rising in the energy transition?

CCS requires raising CO2 pressure above CO2’s critical pressure of 73-bar, to around 100-bar as a good average. We have seen a range of numbers from 60-200 bar. It might take 20MW of compression power to raise 1MTpa of CO2 to 100 bar, per our CO2 compression research.

H2 vehicles may be even more demanding, if these tanks require 10,000 psi (700-bar), which is actually more than that of a standard hydraulic fracturing operation. Often, when we have reviewed H2 patent libraries, they are aimed at handling these high pressures including using tanks made out of high grade materials like carbon fiber.

The very highest pressures we have seen in industrial processes are HPHT oil and gas applications, which can reach 15,000 psi (1,000-bar), and an enormous engineering effort is underway to step up the limits to 20,000 psi (1,350 bar).