This data-file captures steel production costs and CO2 intensities in an integrated blast furnace and basic oxygen furnace steelworks, as underpins 70% of today’s 2GTpa global steel output. Our base case is a marginal cost of $550/ton and 2.4 tons of CO2 emitted per ton of steel.

Blast furnaces reduce iron ore into pig iron, using coke as a reducing agent, and emitting CO2 in the process. Pig iron is then further processed into steel in an adjacent basic oxygen furnace. This pathway underpins 70% of the world’s steel production, of which almost two-thirds takes place in China.

Our base case for steel production, via the blast furnace and basic oxygen furnace route, is at a marginal cost of $550/ton and with 2.4 tons of CO2 emitted per ton of steel.

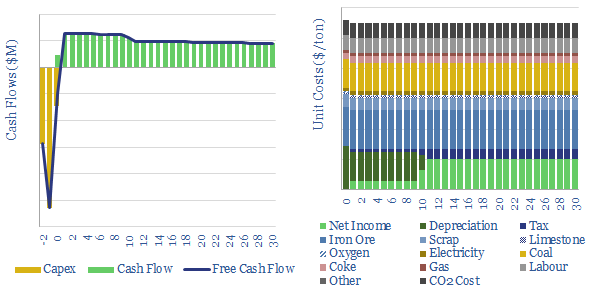

This data-file breaks down the costs of steel from blast furnaces, across a dozen input variables, such as capex, opex, iron ore prices, coke prices, coal prices, gas prices, electricity prices, limestone prices, labor rates and tax regimes.

The economics of blast furnaces are sensitive to input assumptions, which are backed up by technical data, but can also be stress-tested.

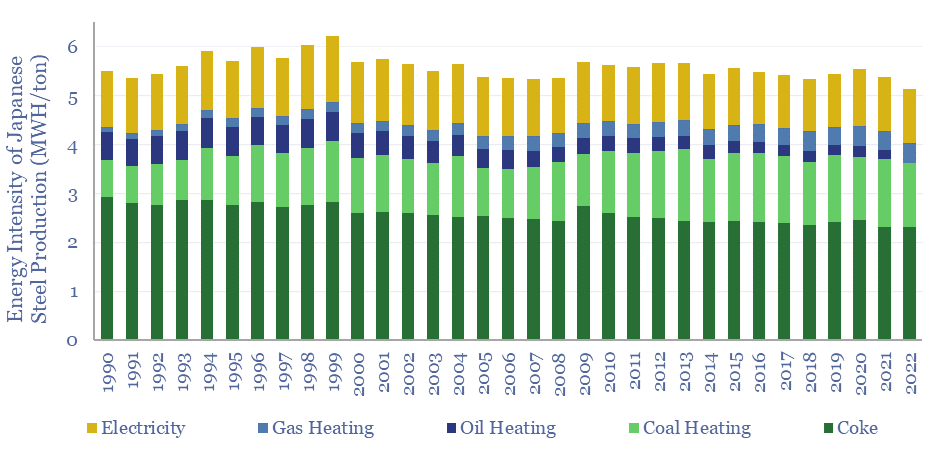

For example, we have undertaken a detailed case study into the energy intensity of Japanese steel production since 1990, declining at 0.8% pa from its peak in 1999 (chart below), to 5.1 MWH/ton in 2022. For comparison, the thermodynamic minimum energy needed to decompose hematite (Fe2O3) into pure iron is 2.1 MWH/ton. This is part of our broader modeling into Japanese energy demand.

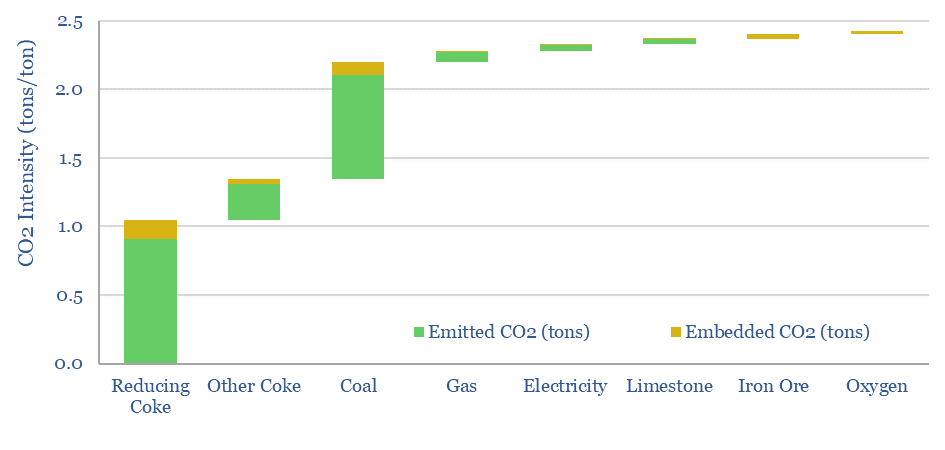

CO2 intensity is around 2.3 tons of CO2 per ton of steel, on a fully loaded basis (waterfall chart below). Further granularity is given in the model, including the workings that lead us to this build-up.

The data-file also allows some evaluation of decarbonization options, including electrification, blue hydrogen and green hydrogen, both as reducing agents and as heating sources. As well as these variables’ impacts on steel production costs.

It is interesting to compare and contrast the economics, and decarbonization options for blast furnace steel with direct reduced iron and electric arc furnace steel. All of our steel research is summarized here.