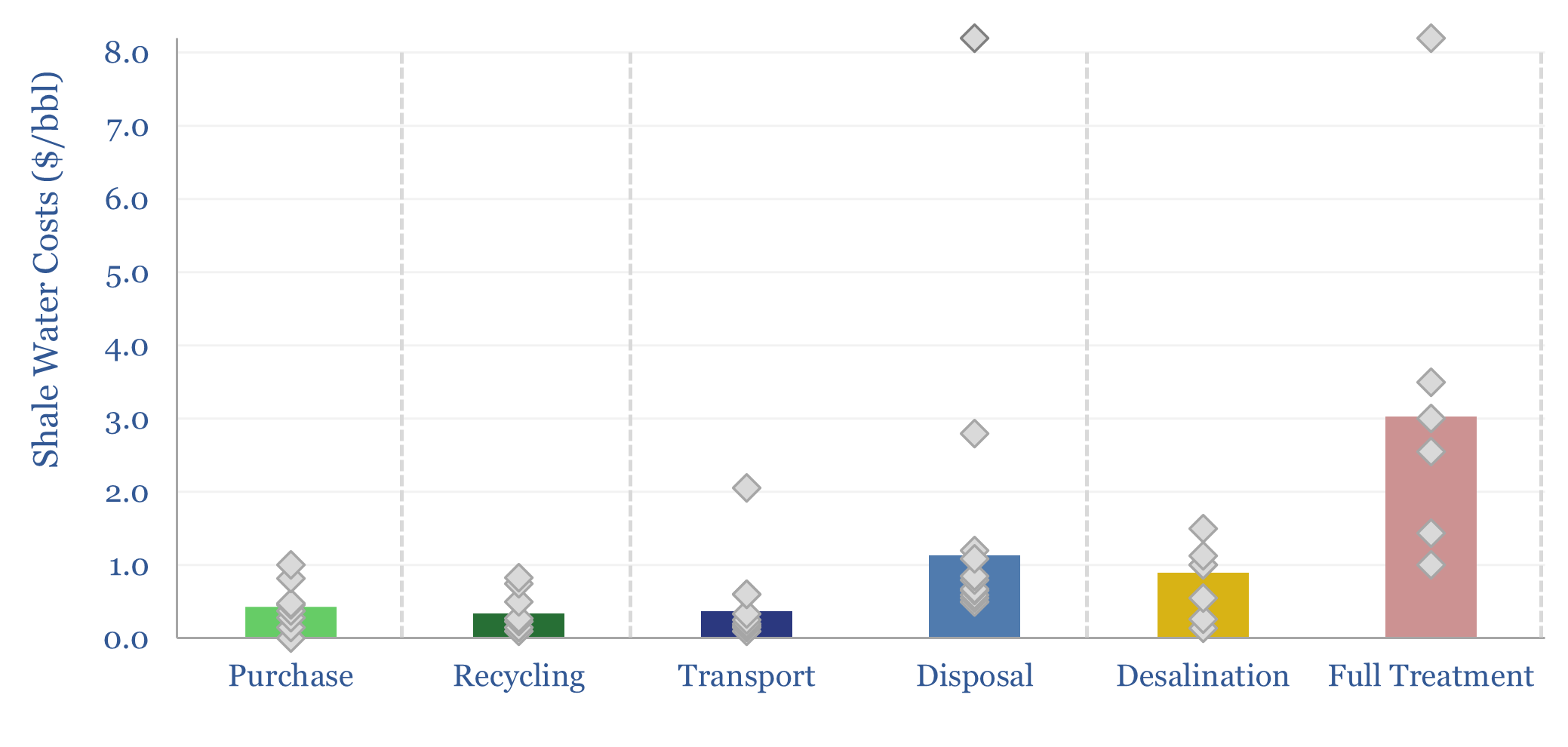

Shale water costs might average $0.3/bbl for filtering and recycling, $0.4/bbl to procure new water, $1/bbl for disposal and $3/bbl for full treatment back to agricultural/cooling-quality water. There is variability in water properties and throughout shale basins. This data-file aggregates disclosures into shale water costs.

The water:oil ratio at a shale oil well might start at 2:1 during flowback, rising to 4:1 at the mid-point of a well’s life and reaching as high as 10:1 for a mature shale well. Hence by early 2025, the Permian basin is producing 20Mbpd of water, and an entire $10bn pa industry exists to handle produced water from the oilfield.

The costs of water in shale basins are tabulated in this data-file, across purchasing, recycling, transporting, disposal, desalination and full treatment of water so that it can be used for irrigation or perhaps for cooling data-centers and power plants such as CCGTs.

Variability in the data reflect different basins, different locations within each basin, and different water properties, which can even vary well by well. For example, salinity of produced water in the Delaware basin is about 2x seawater, while the Midland basin is 2x higher again (data are tabulated in the file).

A 500MW CCGT is going to evaporate off about 75kbpd of cooling water, which is crucial for condensing low-pressure steam, downstream of the CCGT’s steam turbine. It is a nice thought that evaporating off produced water could help to avoid disposal costs of that produced water.

However, it is usually not going to be practical or economical, to use produced water for cooling, as produced water is hyper-saline, contains solids, and nasties such as BTEX and ammonia. Hence full water treatment costs ($3/bbl) will almost certainly exceed disposal costs ($/bbl). This topic is discussed in greater detail in our recent report into power plant cooling.

Recycling produced water for use in future fracturing operations seems more economical, as in many places the costs of filtering and recycling produced water ($0.3/bbl) can avoid both the costs of disposal ($1/bbl) and the costs of purchasing and transporting new water ($0.4/bbl).

Notes on shale water issues, sourced from technical papers, and companies in the shale water value chain, are also highlighted in the back-up tabs of the data-file.