Solvay is a chemicals company with growing exposure to battery materials, especially the PVDF binders that hold together active materials in the electrodes. But also increasingly in electrolyte solvents, salts and additives. Interestingly, our patent review finds optimizations of this overall system can improve the longevity and energy density of batteries, which may also lead to consolidation across the battery supply chain?

Solvay is a chemicals company, listed in Brussels and Paris, with history dating back to 1863, 22,000 employees, €13.4bn of revenues in 2022, 24% EBITDA margin and €11bn of market cap at the time of writing in September-2023.

Its Materials segment produces specialty polymers and composites for light-weighting vehicles and aerospace parts; its Chemicals business produces soda-ash, peroxides, silica, et al; and its Solutions business produces specialty chemicals, aromas, coatings, Rare Earths, mining solutions and battery recycling.

For the energy transition, Solvay is a leading producer of battery binders, which are fluorinated polymers, mainly PVDF, that physically bind the metal particles together in a battery cathode and the graphite particles together in a battery anode. Solvay has the broadest PVDF offering in the battery materials space, spanning across both suspension- and emulsion technologies. And it is investing to expand capacity in France, the US and China. We found some interesting battery binder innovations in the patents.

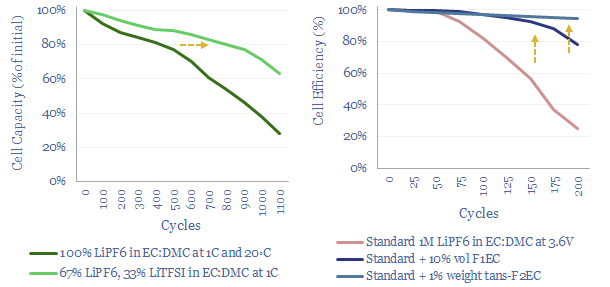

However what surprised us most about reviewing Solvay’s patents was that there was 2x more focus on developing battery electrolytes and additives than on improving binders. Typically, the electrolyte of a lithium ion battery consists of LiPF6, an ionic salt, which is dissolved in ethylene carbonate, dimethyl carbonate or vinylene carbonate. However, this also places a limit on the battery energy density (and by extension, materials intensity), as most of these solvents start decomposing at 4.2-4.4V. For more details, please see our deep-dive report into battery degradation.

The patents strongly imply that electrodes, binders, electrolyte solvents, salts and additives form an ‘overall system’ where all of the components interact. Hence as the battery industry focuses upon lower degradation and higher voltage (more energy dense) battery chemistries, we wonder if this will drive consolidation across the supply chain, where battery manufacturers will want to buy all of these mutually interactive materials as part of an overall offering from a single integrated supplier rather than purchasing them separately?

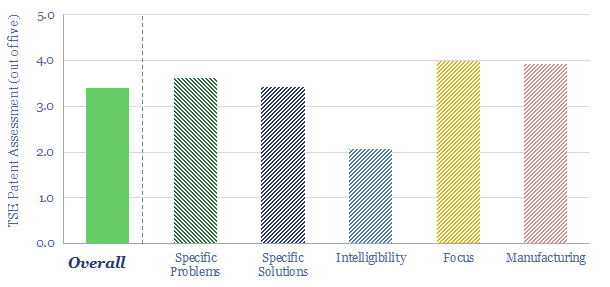

Overall Solvay’s battery patent library is complex, with literally hundreds of different electrolyte salts, solvents and additives and blended together in cocktails. Over 90% of the patents provided specific details of specific compositions, aimed at improving cell longevity, or voltage, or efficiency (charts below).

Back in the world of battery binders, there is also a side focus on developing lithium metal batteries, or solid state batteries. Note that a typical lithium ion battery uses fluorinated polymer binders in its electrodes, but a solid state battery would use fluorinated polymer binders in its electrolyte too.

Please download the data-file for further conclusions from our Solvay battery technology review, and conclusions on whether the company has a moat around its patents.