Search results for: “amines amine”

-

CANSOLV: CCS amine case study?

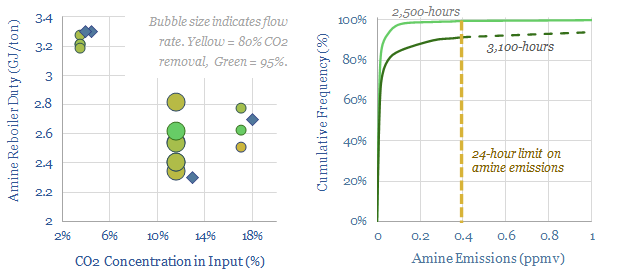

CANSOLV is a proprietary CCS amine being commercialized by Shell since 2014. This data-file aggregates data into its reboiler duties (2.4-3.2 GJ/ton), amine emissions to air (can be below 0.2ppm) and degradation rates (pretty decent, especially up to 2,500 hours). Interest in workable CCS amines has been accelerating since early-2023.

-

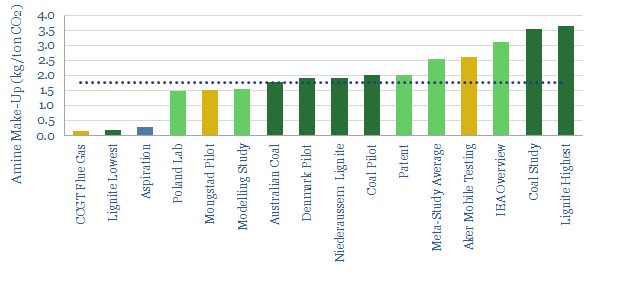

CCS: amine degradation rates?

In post-combustion CCS facilities, amines react with CO2, which can later be re-released via steam-treating, and sent for sequestration. However, CCS plants have amine make-up rates, to replace amines that degrade (chemically, thermally) and evaporate off. This data-file quantifies make-up rates of amines in kg/ton.

-

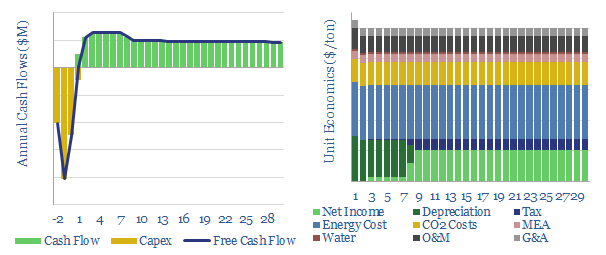

Costs of CCS with the amine process?

This data-file models the economics of capturing CO2 from exhaust flues using the amine process. Our base case estimate is informed by five tabs of cost data and technical papers, but all of the input assumptions can be flexed to stress-test costs. Total costs rise exponentially if it is necessary to capture CO2 from more…

-

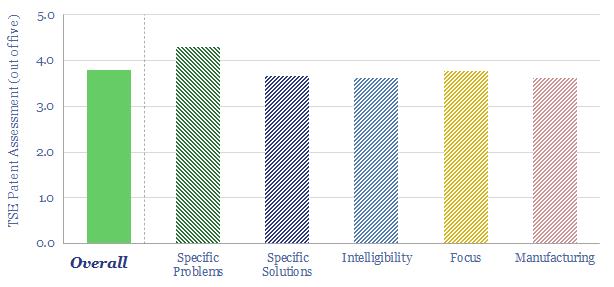

Aker Carbon Capture: technology review?

Aker Carbon Capture is a public company, listed in Norway, with c120 permanent employees. It has developed novel solvents for post-combustion carbon capture, modular CCS plants (JustCatch, at 40-100kTpa, and BigCatch at >400kTpa). The company aims to secure contracts for 10MTpa of CCS by 2025. This technology review looks for a moat in the patents.

-

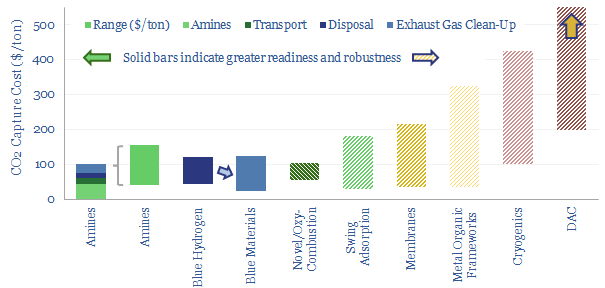

Carbon capture and storage: research conclusions?

Carbon capture and storage (CCS) prevents CO2 from entering the atmosphere. Options include the amine process, blue hydrogen, novel combustion technologies and cutting edge sorbents and membranes. Total CCS costs range from $80-130/ton, while blue value chains seem to be accelerating rapidly in the US. This article summarizes the top conclusions from our carbon capture…

-

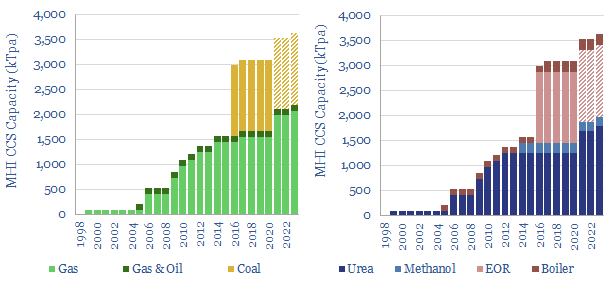

MHI CCS technology: performance, costs and emissions?

MHI has deployed an amine-based CO2 capture technology, in 15 plants globally, going back to 1999. Reboiler duties are around 2.6 GJ/ton on a 10% CO2 feed. Capture rates and capture purity are high. Degradation and amine emissions are controlled, and c80-90% below MEA. CCS costs and complexities remain high. In our view, this is…

-

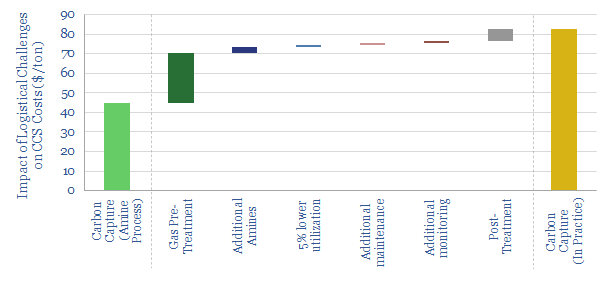

CCS challenges: by any amines necessary?

Post-combustion CCS has more practical challenges than we had previously assumed, which are explored in this 13-page report. Today’s established amines require extensive pre- and post-treatment of gases; to prevent degradation, plant corrosion and toxic emissions. This might double real-world CCS costs. But it also creates more opportunity for novel CCS processes, which are rapidly…

-

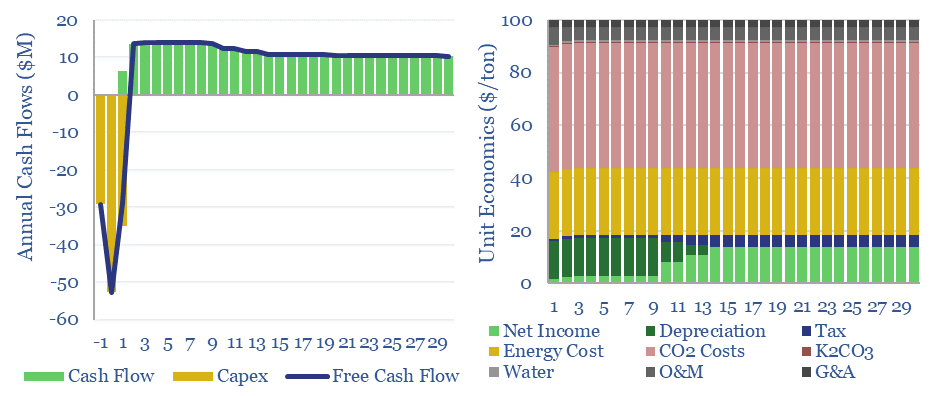

Hot potassium carbonate CCS: energy economics?

Hot potassium carbonate is a post-combustion CCS technology that bypasses the degradation issues of amines, and can help to decarbonize power, BECCS and cement plants. We think costs are around $100/ton and energy penalties are 30-50%. Potassium carbonate CCS can be stress-tested in this data-file, across 50 inputs.

-

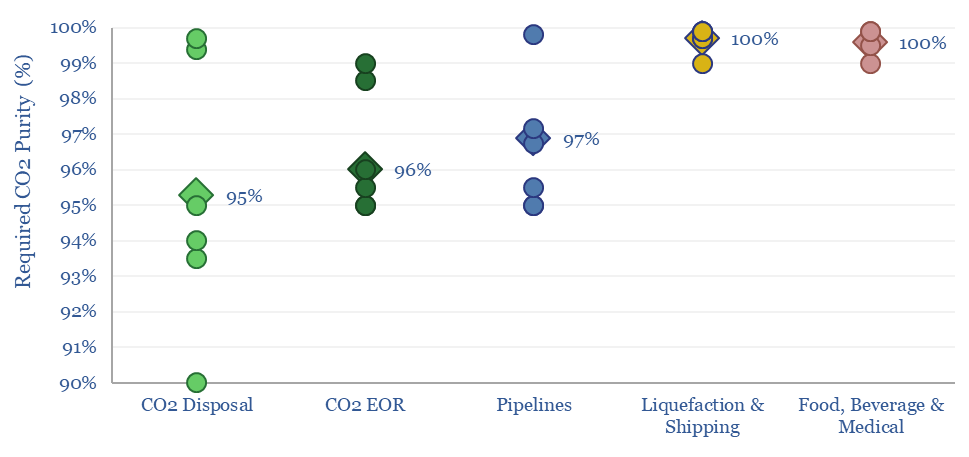

CCS: what CO2 purity for transport and disposal?

The minimum CO2 purity for CCS starts at 90%, while a typical CO2 disposal site requires 95%, CO2-EOR requires 96%, CO2 pipelines require 97% and CO2 liquefaction or shipping requires >99%. This data-file aggregates numbers from technical papers and seeks to explain CO2 purity for transport and disposal.

-

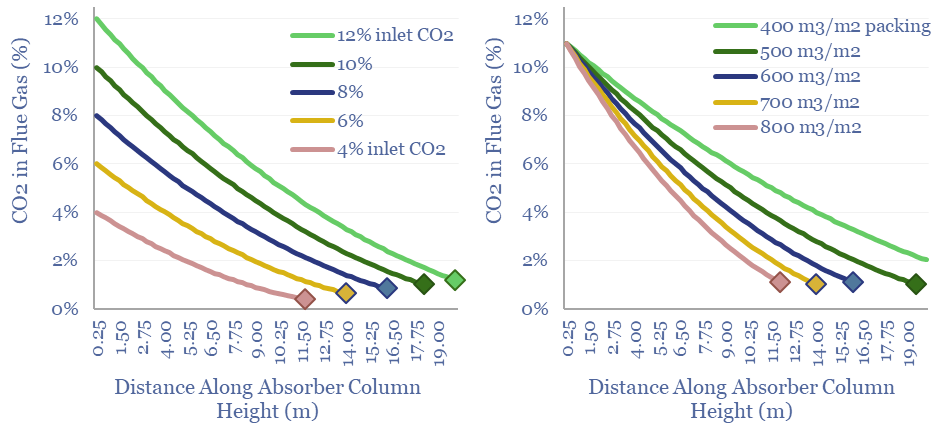

CCS absorbers: unit sizing and residence times?

Post-combustion CCS plants flow CO2 into an absorber unit, where it will react with a solvent, usually a cocktail of amines. This data-file quantifies operating parameters for CCS absorbers, such as their sizes, residency times, inlet temperatures, structural packings and the implications for retro-fitting CCS at pre-existing power plants.

Content by Category

- Batteries (89)

- Biofuels (44)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (94)

- Data Models (838)

- Decarbonization (160)

- Demand (110)

- Digital (59)

- Downstream (44)

- Economic Model (204)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (279)

- LNG (48)

- Materials (82)

- Metals (80)

- Midstream (43)

- Natural Gas (148)

- Nature (76)

- Nuclear (23)

- Oil (164)

- Patents (38)

- Plastics (44)

- Power Grids (130)

- Renewables (149)

- Screen (117)

- Semiconductors (32)

- Shale (51)

- Solar (68)

- Supply-Demand (45)

- Vehicles (90)

- Wind (44)

- Written Research (354)