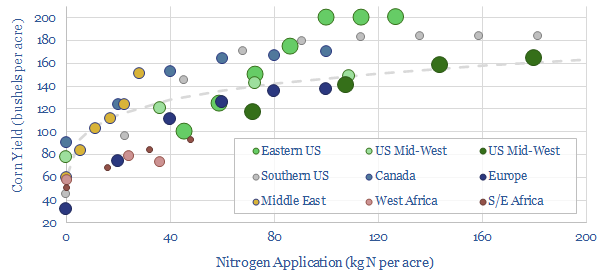

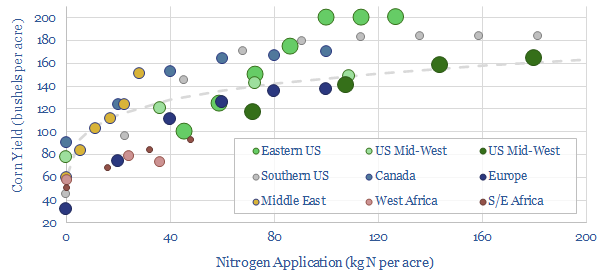

…by the time of maturity. These ears contain so much nitrogen than around 70% is sourced by remobilizing nitrogen out of leaves and stems. How much does fertilizer increase crop…

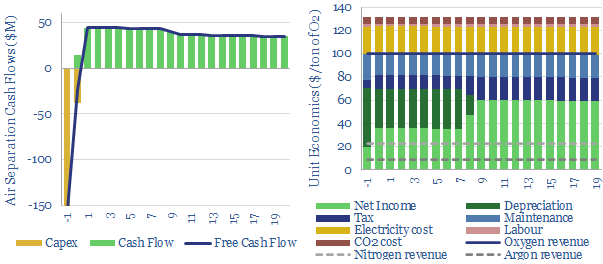

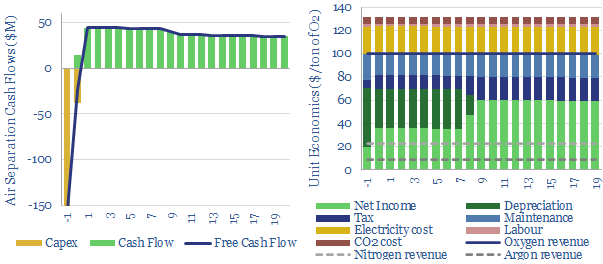

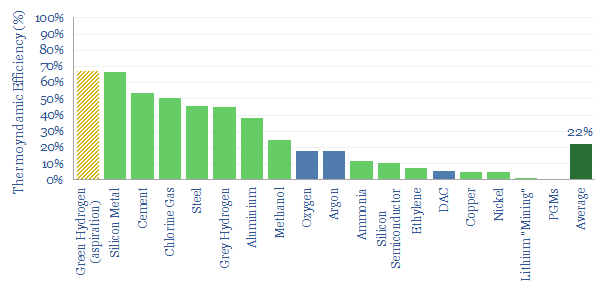

…selling nitrogen and argon. We estimate a nitrogen price of $20/ton is required for an air separation unit that feeds into an ammonia plant and derives some revenues from commercializing…

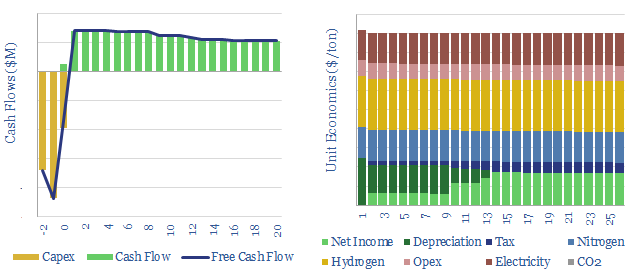

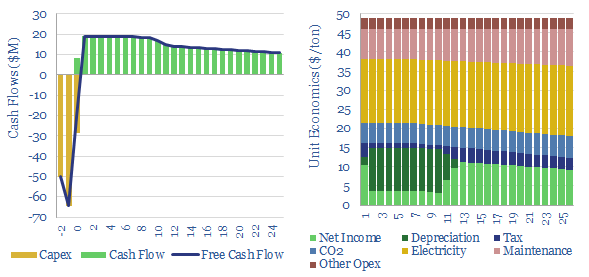

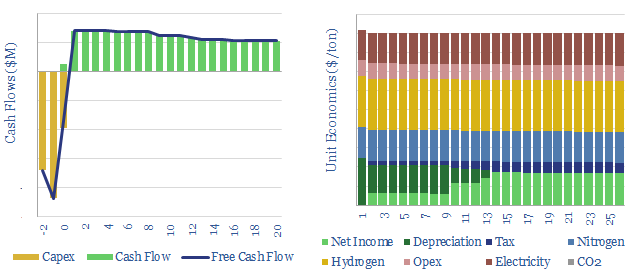

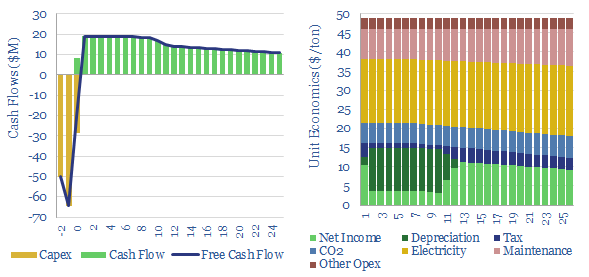

This data-file captures ammonia production costs and energy economics, starting from inputs of hydrogen and nitrogen, using the Haber-Bosch process. Our base case is $400/ton NH3 and 2.4 tons/ton CO2…

…its constituent elements, i.e., gaseous hydrogen and gaseous nitrogen. Pure hydrogen does not occur naturally, but itself needs to be produced, most likely by steam methane reforming. And pure nitrogen…

…to $20/ton in next-generation membranes. $499.00 – Purchase Checkout Added to cart A good membrane for CO2 capture should have a CO2 selectivity (versus Nitrogen) above 125x, and a CO2 permeance above…

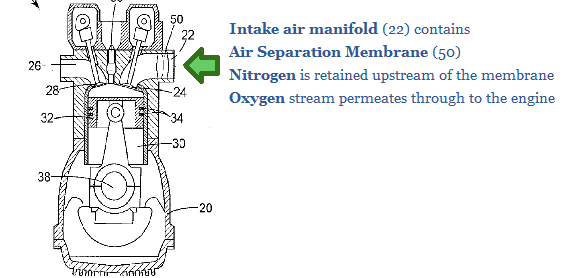

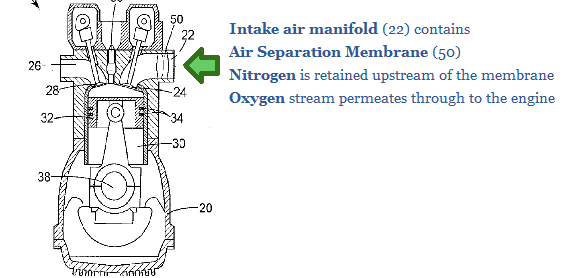

…exhaust gas by burning fuels in an atmosphere that has been purged of Nitrogen (e.g., pure oxygen and CO2). This means that the exhaust gas will comprise CO2 and H20…

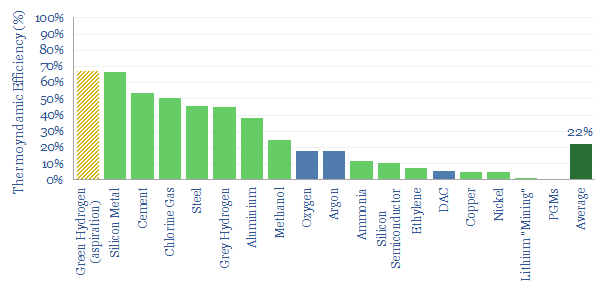

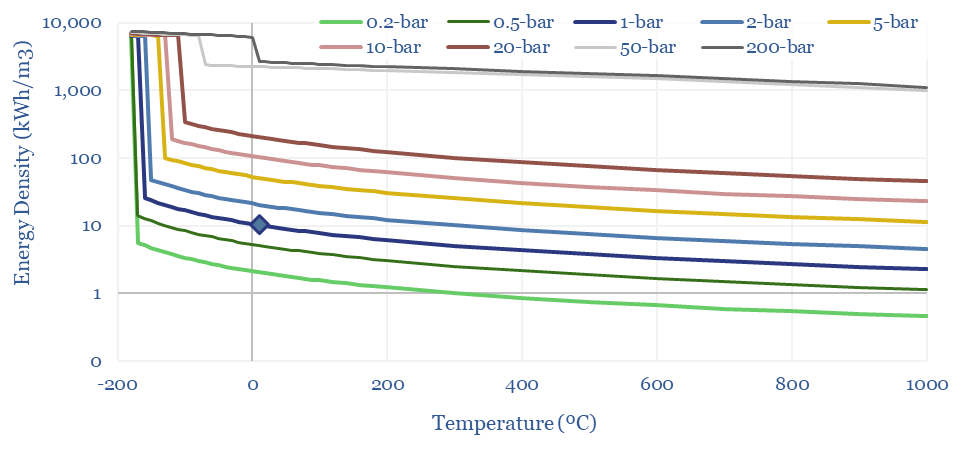

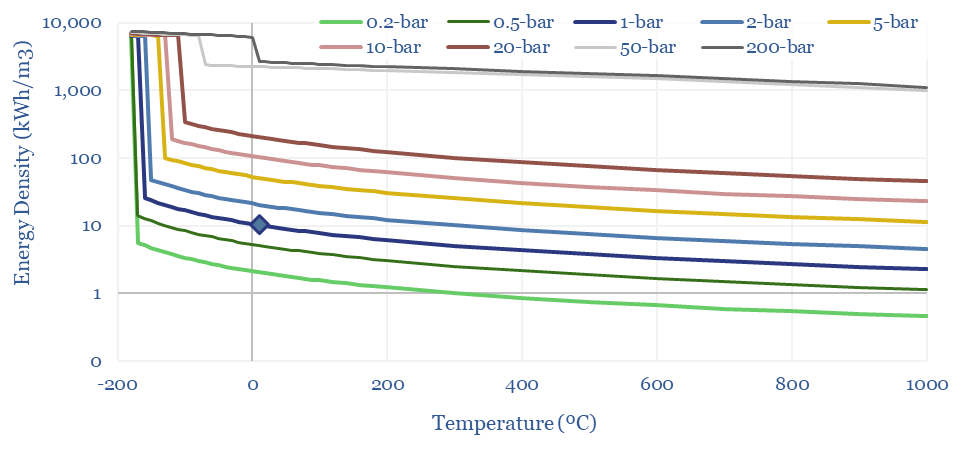

…and the Clausius-Clapeyron Equation. High energy density is shown for methane, less so for hydrogen and ammonia. CO2, nitrogen, argon and water are also captured. $499.00 – Purchase Checkout Added to cart…

…to separate CO2 (4-40% concentration) from air (mostly nitrogen). Amines can do this, but the process is costly, energy intensive and amines can be degraded by contaminants. Oxy-combustion is an…

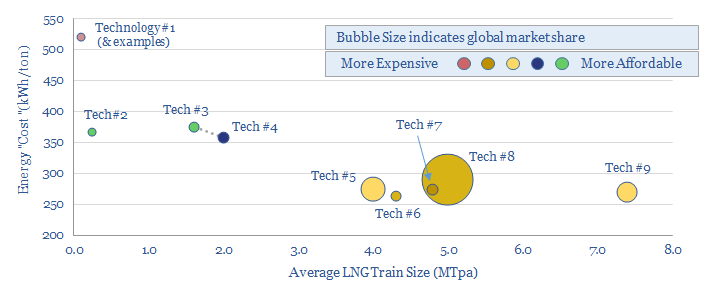

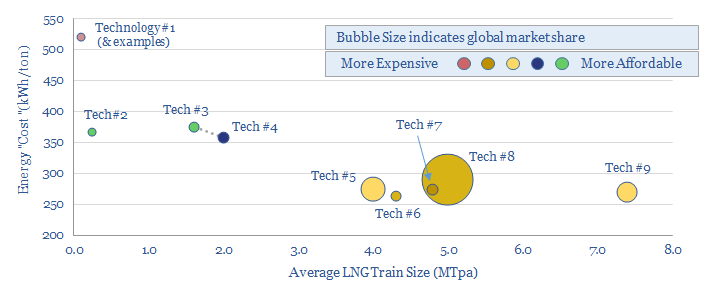

…50% ethane, 27% methane, 20% propane, 2% butane, 1% nitrogen. The APX process adds a nitrogen loop. What heat exchangers are used in LNG cycles? APCI and APX use spool-wound…

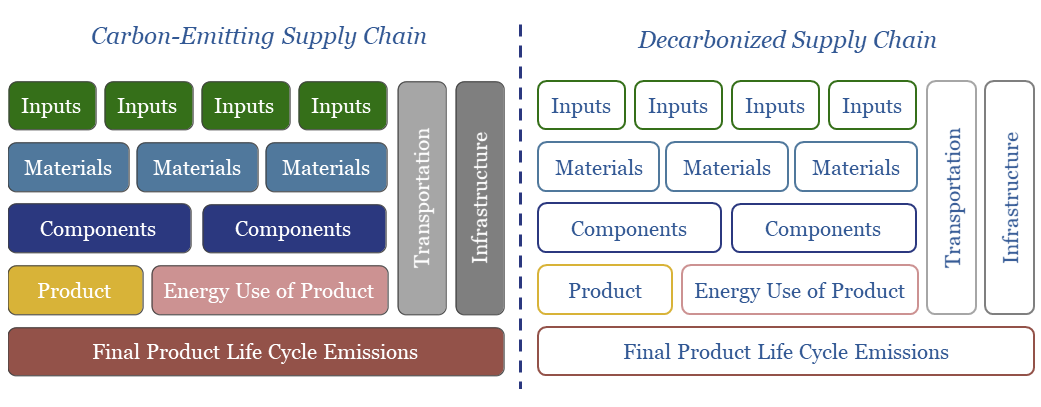

…carbon fiber. It is unbelievably complex. Our “simplification” only contains 25 different stages. The most energy intensive is rejecting the nitrogen groups from poly-acrylonitrile (23 tons of CO2 per ton…