“If you wish to make an apple pie from scratch, first you must invent the universe”. This Carl Sagan quote also applies to the decarbonization of complex supply chains. If you truly want to decarbonize an end product, you must decarbonize every single component and input, which may be constellated across hundreds of underlying suppliers. Hence this note argues that each company in a supply chain should aim to drive its own Scope 1&2 CO2 emissions towards ‘net zero’. The resulting products can be described as “clear”, “transparent” or “translucent”.

The complexity of global supply chains

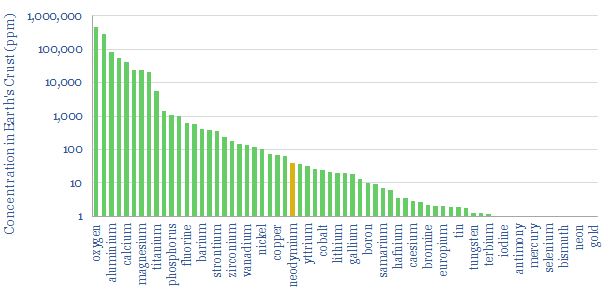

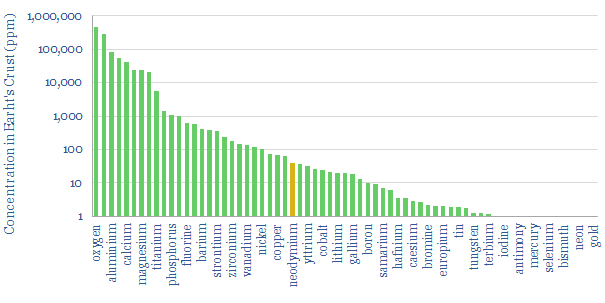

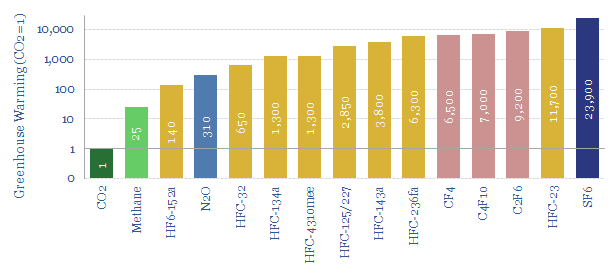

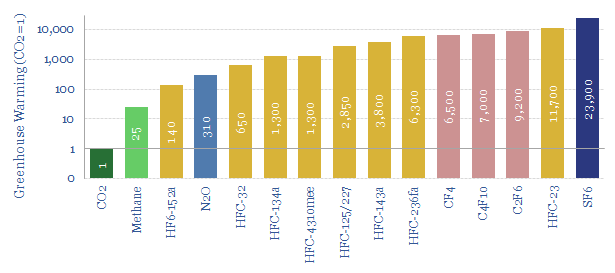

A key focus of our recent research has been materials that are needed in the energy transition. Examples are carbon fiber (used in wind turbine blades and hydrogen storage tanks), photovoltaic silicon (used in solar panels), lithium (used in batteries), neodymium magnets (used in wind turbines and EVs), dielectric gases (used in electricity distribution) or even something as simple as cleaning up 2GTpa of global steel production.

What has stood out is how complex different supply chains are. It would be nice if there was a button you could press, somewhere in a steel mill, with a big shiny label that said “decarbonize steel”. The reality in our model (below) is that CO2 emissions originate from around a dozen processes and inputs, each of which would need to be decarbonized in turn.

The value chain is also shown below for producing another material, carbon fiber. It is unbelievably complex. Our “simplification” only contains 25 different stages. The most energy intensive is rejecting the nitrogen groups from poly-acrylonitrile (23 tons of CO2 per ton of carbon fiber) at 1,000-3,000°C, in atmospheres composed of pure industrial gases, such as argon and nitrogen. But again, every single material in the schematic has an increasing CO2 footprint, as it is made from whatever preceded it.

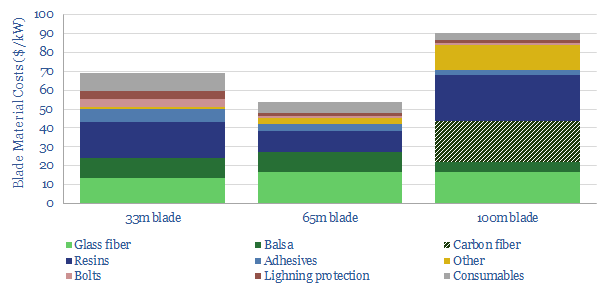

So if you wanted to make a truly zero-carbon wind turbine, how on Earth would you do it? A rule of thumb is that each MW of turbine capacity uses 150 tons of steel (discussed above, an annoyingly complex value chain). And the blades of a cutting-edge 11MW wind turbine are apt to weigh about 50 tons each, of which 5% is carbon fiber (discussed above, with an even more complex value chain). The remainder of the blades are also made up of 20 other input materials (chart below, data-file here), which will all have their own complex supply chains. And this is just one product, out of millions of products that needs to be decarbonized.

The challenge, we think, is that producing ‘carbon neutral’ wind turbines does not just require the turbine manufacturer to drive down the emissions in its manufacturing facilities to net zero. If they are purchasing CO2-emitting steel from one supplier, CO2-emitting carbon fiber from another supplier, and CO2-emitting Xs from dozens of other suppliers, then the end product will embed that CO2 as a consequence. The same goes for any manufactured product you might care to consider in detail.

It might be tempting to shy away from the challenge of decarbonizing complex supply chains. “Who needs to decarbonize wind turbines, they are already green?”. However, this logic is dangerous. Net zero means net zero. Globally. Universally. I.e., every single supply chain needs to get to net zero. That is the definition of net zero. It would be fair to adapt the Carl Sagan quote as follows. “If you wish to decarbonize an apple pie from scratch, first you must decarbonize the universe”.

A Roadmap for Decarbonizing Complex Supply Chains?

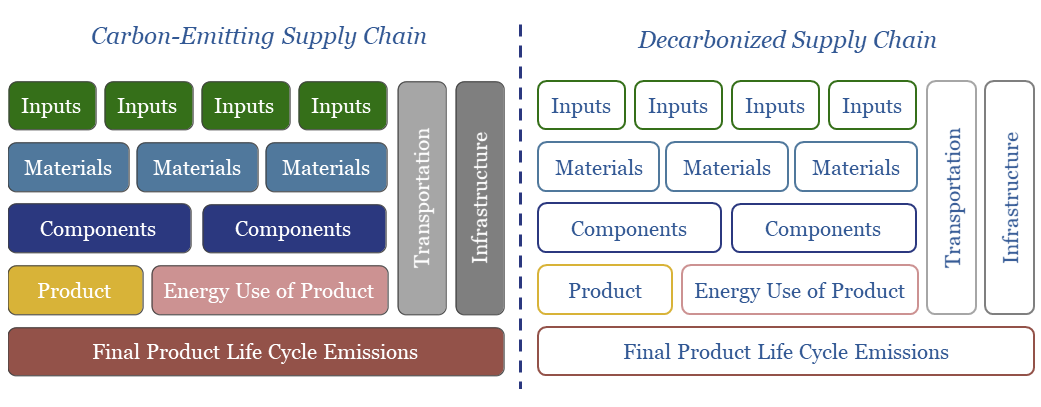

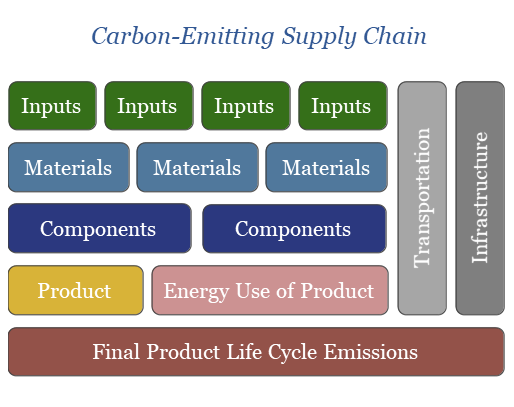

In order to simplify the complexity, let us move away from any specific example and consider the schematic below, which builds up the total life-cycle emissions of a generic product. The first step is producing primary materials, which are grown on land or extracted from the Earth. These will be upgraded or refined into usable materials. This materials will be formed or combined into components. The components will be manufactured into an end product. The end production will consume energy, in various forms, over its useful life.

In addition, at every step along this chain, the different components need to be transported from one location to another. And all of this supervenes on an infrastructure network of roads, rails, ports, electricity distribution networks and computer servers.

The total life-cycle CO2 emissions of a product is the sum of every single component step in the value chain. If the product uses 1kg of Material A, and Material A has a CO2 intensity of 2 kg/kg, then the product will embed 2kg of CO2, simply due to Material A. And so on, for all of the other component steps. Of course, the exact numbers will vary product-by-product.

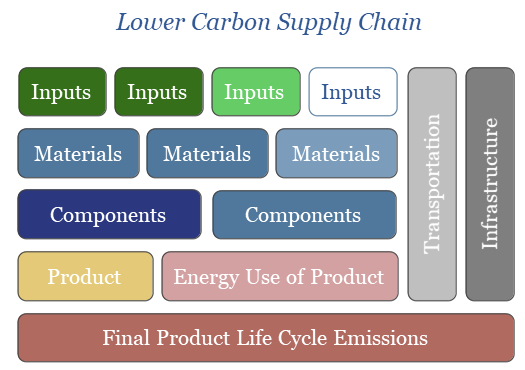

The challenge that we noted above, is that a typical product will gather tens-hundreds of inputs from tens-hundreds of suppliers. However, in the chart below we consider what happens if one of the input-producing companies in this value chain aims to become ‘carbon neutral’, possibly using the mixture of options available to them on Thunder Said Energy’s roadmap to net zero. Their product will have no embedded CO2. This means there will be less CO2 embedded in the materials made from that product, and in turn less CO2 embedded in the components made from that material, and so on, cascading up the chain.

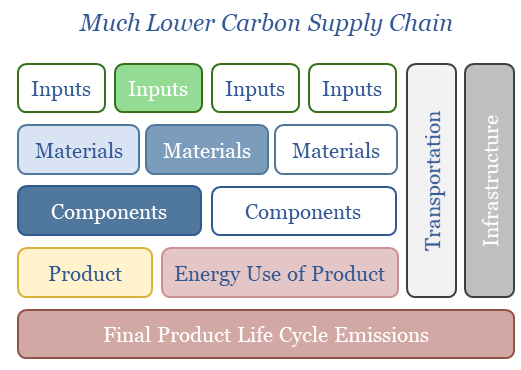

It is not difficult to imagine that more and more companies across the chain might also make progress with net zero ambitions, lowering (lighter color) or removing all of the net CO2 from their production process (clear blocks). Again, this can cascade up the chain and lower the net CO2 emissions embedded in the final product.

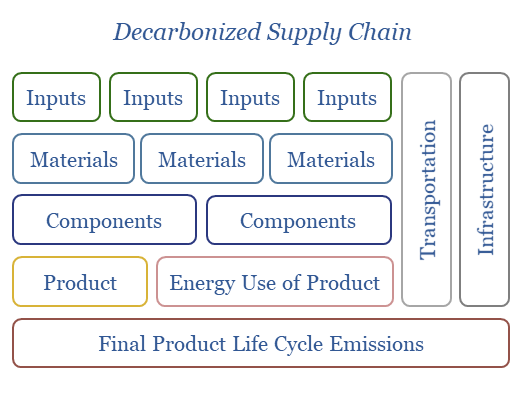

The end goal, we might hope, is that every single supplier across the value chain reaches net zero, and thus the entire value chain combines to produce a completely carbon-neutral product (chart below).

Implications and conclusions?

If we use the simple schematics above as a roadmap for decarbonizing complex value chains, then several conclusions are likely to leap out…

For companies, you have direct control over your facilities and processes. Your primary objective should be to drive down net CO2 emissions from your facilities and processes, ideally towards zero; as this will cascade constructively through overall supply chains. We are currently working with dozens of companies to help them evaluate the most economical and practical route to do this.

For procurement teams, you have control over where your components, materials and inputs come from. Your objective should be to procure lower-CO2 products and services, where that is practical. Again, this will cascade constructively through overall supply chains.

For consumers, you have control over your purchasing and your emissions. You can act to minimize and offset both if you want to (screen of options below).

For critics, it may be unfair to ‘bash’ companies for emissions that are downstream of their facilities and processes. For example, an oil and gas company might aim to remove all of the net Scope 1&2 CO2 from their operations, but then get criticized by environmental groups for not tackling their Scope 3 emissions too. In some cases, this criticism may be fair: for example when the words in company marketing materials have been poorly chosen (more on this topic below). But more broadly, we think the approach is right. Global supply chains are complex. They are so complex that the only way to decarbonize them is if each company takes responsibility for their own link in the chain. In our own schematics for decarbonizing complex supply chains, oil and gas companies’ Scope 3 emissions are the responsibility of energy consumers further down the value chain, to displace, reduce, capture and offset.

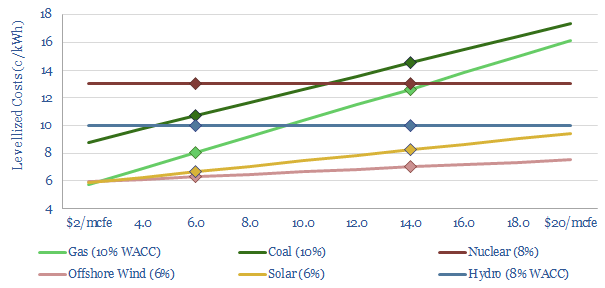

For policy-makers, it would be helpful to impose an economy-wide carbon price, which in our view, should be set in the range of $50-100/ton. Its goal is to incentivize any and all actions that can lower net CO2 intensity at a cost below $50-100/ton. Ideally it should be combined with tax breaks elsewhere, so that the overall tax burden across the economy does not rise, as this would be inflationary. Ideally it should tax CO2 on a net basis, after deducting the impacts of CCS and high-quality nature-based CO2 removals, otherwise the total costs of reaching net zero are around 10x higher (15% of global GDP vs 1.5% of global GDP). Ideally it should promote carbon-labelling, as products that do not report transparent CO2 intensities would be assumed to have higher CO2 intensities than products that do report it. And ideally it would include a border-adjustment mechanism, to prevent carbon leakage. These are views based on all of our research to-date.

For the tech industry, we are sure that there is a clever, billion-dollar solution to indexing the embedded CO2 across entire value chains; so that one day, a consumer could pick up a product from a shelf, and instantly get a reading of its precise, embedded CO2 content, and its exact breakdown, along a complex value chain. The process might use a blockchain technology, or a simple set of relational databases, although the CO2 intensity of the blockchain should be minimized (note below).

For the global economy, adding a cost of decarbonization to every step of a value chain is going to inflate the overall costs across that value chain. This is inflationary. It is why we think low cost decarbonization is crucially important, and we have now conducted over 750 pieces of analysis to find the lowest cost options to reach net zero.

New Terminology: Lost for Words?

A constructive conclusion from our ongoing discussions with dozens of companies is the growing appetite to reach ‘net zero’. Genuinely, measurably, in the most practical and cost-effective way.

A major hindrance, however, is that the terminology does not yet exist to describe the kind of supply chains we have outlined above, where each company strives to ensure that its own individual link of the chain is carbon-neutral.

For example, imagine you are a producer, and you have worked to drive the net Scope 1 & 2 emissions of your product down to zero. You have integrated renewables into your operations as best you can, sought as many efficiency gains as possible, you may be sequestering CO2 back into the sub-surface, and/or you may be offsetting residual CO2 emissions using nature-based carbon removals. What should you call the resultant product?

“Zero carbon” or “Carbon Neutral”. Our view is that this is not the right terminology for such a product, because there could still be CO2 embedded in input materials, and associated with the use of the product. For example, if an auto-maker had removed all of the Scope 1&2 emissions from its auto plant, it would be misleading to call this a “carbon neutral car”, because there would still be CO2 associated with fueling the car, and CO2 embedded in the materials and components arriving at the auto plant.

“Lower-carbon”, “Clean” or “Green”. Our view is that this is not the right terminology, because it is imprecise. It does not capture the absolute nature of having driven Scope 1 & 2 emissions down to zero, but suggests something that is a matter of degrees. Moreover, if a coal-producer had removed all of the Scope 1&2 emissions from their coal production process (50kg/boe), then it might also be misleading to label the product as “clean coal”, because it would still contains 750kg/boe of Scope 3 emissions, which would be 2.3x more than “non-clean” natural gas, confusingly.

“Clear”. There has been a recent trend towards describing energy products with colors, especially in the hydrogen industry. At the risk of exacerbating this colorful trend, we think the best terminology is to describe a product with zero net Scope 1 & 2 emissions embedded within it as “clear”. Clear means that the product is “clear” from embedded CO2 emissions. For example, “clear steel” means steel whose production has not emitted any net Scope 1 & 2 emissions (and the same goes for “clear carbon fiber” or “clear natural gas”). In other words, labelling a product as “clear” advertises to its purchaser that there is no Scope 1 & 2 CO2 embedded in the product. The purchaser may emit CO2 via their use or processing of the product. But if they can capture or offset this CO2, in turn, then their own end product can also be described as “clear”. This is the only way we can see to create carbon-neutral products across the complex value chains we described above.

“Transparent”. It would also be useful to have a word for production processes that have not added any net Scope 1 & 2 CO2, but where the products still embed whatever CO2 was already embedded in their own input materials. For example, a manufacturing facility might be run entirely off of renewable electricity as its sole electricity source. This means it has not added any net CO2 into its product. Although there may have been CO2 embedded in the components and input materials that were brought into the manufacturing facility. The manufacturing process is “transparent” in the sense that whatever CO2 was embedded in the input materials still shows through.

“Translucent” might be used to connote a process that is almost transparent, but has still added some small amount of CO2. Ideally, this CO2 can be quantified. For example, a manufacturer might have lowered its CO2 intensity by over 80%, compared to some baseline; but wish to honestly reflect that there are still some residual CO2 emissions that cannot be quantified or have not been entirely offset yet.

“Opaque” might be used for a product or process where there is clearly CO2 embedded, but it cannot even be quantified. One of the biggest present challenges in complex global supply chains is that almost all of the products are opaque.

Our conclusion on is that using these terms, consistently, across hundreds of decarbonizing companies, would be helpful for avoiding misunderstandings and building trust in the decarbonization of complex supply chains. Our own work in 2022 will start using the three terms — “clear”, “transparent” and “translucent” — in line with the definitions above.