CANSOLV CCS amine has been commercialized by Shell since 2014. This data-file aggregates data into its reboiler duties (2.4-3.2 GJ/ton), amine emissions to air (can be below 0.2ppm) and degradation rates (pretty decent, especially up to 2,500 hours). Interest in workable CCS amines has been accelerating since early-2023.

CCS has seen a huge uptick of interest in 2022, including due to the IRA. But key challenges are amine stability (note here) and energy penalties (note here), which may not be entirely workable for commoditized amines such as MEA, in our view. Hence the hunt for better amines.

CANSOLV is the brand-name for a proprietary post-combustion CCS process, being commercialized by Shell, using the amine-based solvent, DC-103, plus other amines and additives. Some sources say that DC-103 is an activated tertiary amine. It is also selective to absorbing SO2. The solvent was developed by a spin-out from Union Carbide, Cansolv Technologies Inc, which was in turn acquired by Shell in 2008.

Commercially deployed. SaskPower’s coal-fired plant at Boundary Dam has used Cansolv since 2015, under a $1.5bn and 1MTpa CCS project. Although net output at the CCS-linked unit has reduced from 160MW to 110MW by running CCS. And performance has been erratic. The annual run rate for CO2 capture in 2015-21 ranges from 0.37-0.8MTpa and averaged around 0.65MTpa. This is most likely due to mechanical issues at the plant rather than issues with the solvent.

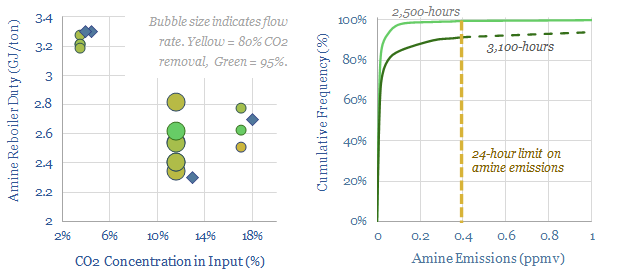

Solvent degradation has been relatively well tested, including in 2019, at a waste incineration plant in Norway (detailed notes in this data-file). In the first 2,500 hours of the solvent’s life, amine emissions were below a 0.4ppm limit level, on a daily averaged basis, over 99.5% of the time, while no significant breakdown products were released.

However, amine releases and breakdown product concentrations did increase in this pilot project over time. In hours 2,500-5,100, degradation of the amines progressively increased to about 10%, while amine emissions were in the range of 1-7 ppm about 4% of the time. We think this was triggered by ESP upsets, and rapid ramp-up/ramp-down of the plant. It could be mitigated by aerosol mitigation devices. Or simply by replacing the solvent after 2,500 hours.

In a 2021 technical paper, a maximum amine emission level of 0.2 ppmv was targeted after the water wash, in simulations around a CCGT. Even with operational upsets, relatively young solvent (up to 1,800 hours) did not materially exceed 0.1 ppmv emission over 24-hours, including spikes due to plant upsets.

Thermal energy needed for amine regeneration (i.e., reboiler duty) is most likely around 2.5 GJ/ton for coal-fired configurations (10% CO2 in exhaust) and rises to 3.1 GJ/ton for gas-fired configurations, based on technical data. This can be compared with other amines here. Economics of post-combustion CCS using amines can be stress-tested here.

Underlying data and further notes are in the data-file. So far, we think Shell’s CANSOLV and Aker Carbon Capture’s JustCatch are two of the front-runners in technically ready CCS amines. All of our CCS research is summarized here.