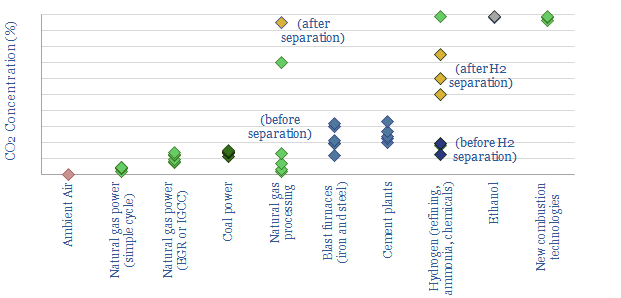

What are the typical CO2 concentrations in exhaust gas streams? The aim of this data-file is to compile data, expressed as a molar percentage of flue gas. This matters for the costs of CO2 separation (e.g., the amine process).

Good rules of thumb for the CO2 concentrations in exhaust gas streams are that a simple gas boiler or burner will have 4% CO2 in its exhaust gas, rising to 8-12% with exhaust gas recirculation, and rising further, to 10-12% at a typical coal-fired power plant.

Industries like cement kilns and blast furnaces can have 10-40% CO2 in their exhaust gas. Ethanol and LNG plants are higher again, and can produce almost pure CO2.

Costs will generally be c10-15% lower to separate out CO2 in middling processes such as blast furnaces and cement plants, compared to lower concentration processes such as coal and combined cycle gas plants.

Costs of separating CO2 from ambient air will be an order of magnitude higher again (at least c4-6x, as costs rise linearly as concentrations fall by each order of magnitude). This is one of the challenges for DAC.

Most promisingly, some CO2 is already purely concentrated (e.g., after pre-treating natural gas before LNG liquefaction; or after separating out industrial hydrogen from SMR in the refining, ammonia, chemicals and blue hydrogen industries). These are the most promising options for CCS, in our view.

This simple data file aggregates data into the CO2 concentrations in exhaust gas streams. Another interesting parameter to explore for CCS projects is the size of the emissions source. All of our broader CCS research is available here for TSE clients.