Gas fractionation separates out methane from NGLs such as ethane, propane and butane. A full separation uses up almost 1% of the input gas energy and 4% of the NGL energy. The costs of gas fractionation require a gas processing spread of $0.7/mcf for a 10% IRR off $2/mcf input gas, or in turn, an average NGL sales price of $350/ton. Costs of gas fractionation vary and can be stress tested in this model.

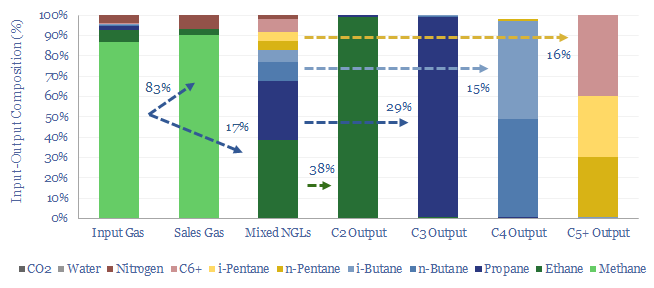

Wellhead gas is mainly composed of methane, it also contains propane, butane, C5s and C6+ fractions, which are entrained in the gas. These condensates or natural gas liquids (NGLs) can be removed by first dehydrating the gas, then, cryogenically cooling it, to ‘drop out’ all of the NGL fractions in a demethanizer (chart below). (For more details, we have written an overview of cryogenics)

The NGLs may then be heat exchanged with steam or warm oils, to warm them back up, and fractionate out the components: with ethane evaporating first in the de-ethanizer (boiling point is -89 °C), next propane in the depropanizer (boiling point is -42ºC) and butane next in a debutanizer (-1ºC). There may be separate stages to separate n-butanes from i-butanes.

The process can vary. Some facilities only drop out mixed NGLs, which are then shipped onwards. Others will cool the gas to separate out C3+, but will leave the ethane entrained, due to limited ethane uses outside of ethane crackers. You can flex these options in the data-file. But our base case captures a full separation of all NGL fractions.

Energy costs of full natural gas fractionation will come to 113kWh/ton of input gas (using up 1% of its energy content) and 600kWh/ton of NGLs (using up 4% of its energy content).

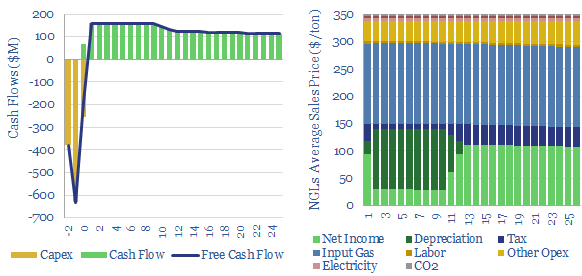

Capex costs of full natural gas fractionation can be estimated with the simple rule of thumb of around $1M/mmcfd of demethanizer capacity plus $5M/kbpd of NGL fractionation capacity. This is based on past projects, tabulated in the data-file.

The costs of a natural gas fractionation plant require a fractionation spread of $0.7/mcf of input gas processed, in order to separate all the NGL fractions and earn a 10% IRR. In other words, if the input gas price is $2/mcf, then the fractionation plant needs to charge a blended average of $2.7/mcfe on sales gas and the various NGL products.

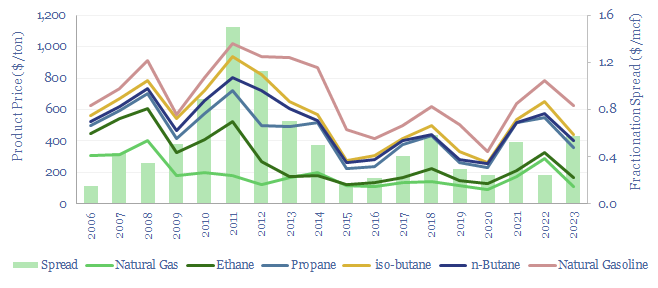

What NGL prices are needed for a 10% IRR? At $2/mcf, our model requires a blended price around $350/ton, across ethane, propane, butanes, and higher fractions. Recent pricing is below, based on data from the EIA. Each $1/mcf on the gas price requires a further c$80/ton onto the required average NGL price.

NGL fractionation is increasingly important to provide feedstocks for advanced polymers used in new energies and energy efficiency technologies. But we also see a growing role for low-carbon natural gas in the energy transition. And fractionation is usually done before natural gas is liquefied into LNG.

Leading companies operating natural gas fractionation plants are constellated around the upstream and midstream industries, while companies such as Technip, Linde, Lummus and other industrial gas companies and oil service companies supply equipment and technology for NGL fractionation plants.