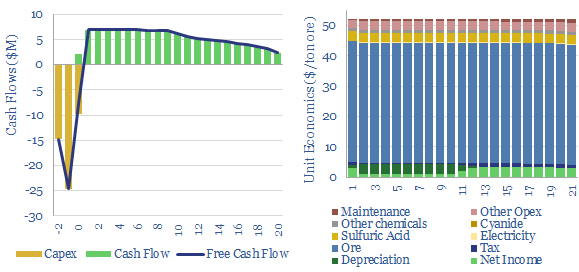

This data-file captures the energy economics of leaching processes in the mining industry, especially the costs of heap leaching, for the extraction of copper, nickel, gold, silver, other precious metals, uranium, and Rare Earths. The data-file allows you to stress test costs in $/ton of ore, $/ton of metal, capex, opex, chemicals costs, energy intensity and CO2 intensity.

How does heap leaching work? A sloping area of 500,000 to 1,000,000 m2 is excavated, lined with a polymer membrane (e.g., HDPE). Gradually, finely ground ore is added, reaching typical heights of around 10 meters, or around 15 tons of ore per m2. As the ore piles up, leaching chemicals are sprayed onto the surface. Sulphuric acid dissolves metals such as copper. Sodium cyanide forms soluble complexes with PGMs.

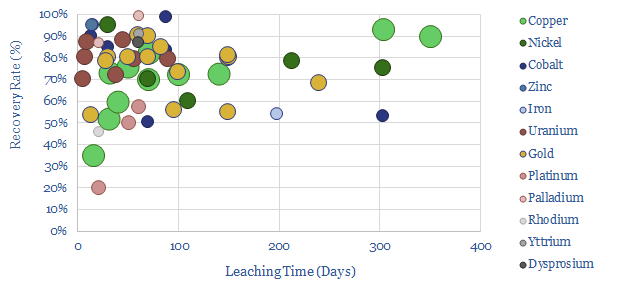

75-85% of the valuable metals might thus be extracted in the pregnant leach solution, which drains off (chart below). This leach solution is then accumulated for further processing, for example, by electrowinning.

The typical costs of heap leaching with H2SO4 might contribute $2.5/kg to the costs of processing an industrial metal, under typical input assumptions. Energy consumption and CO2 intensity are both very low. Most likely around 2kWh/ton of ore; with a fully loaded CO2 intensity of 4 grams per ton of ore.

The typical costs of heap leaching with NaCN might contribute $2-30/Oz to the costs of processing a precious metal, depending on the ore grade. Despite the very low energy cost per ton of ore, the numbers are amplified by an order of magnitude by very low ore grades.

For example, if an ore contains 40 grams/ton of gold-equivalents, and heap leaching recovers 80% of this material, then you will need to process c30 tons of ore to recover 1 kg of gold-equivalents (or 30,000 kg per kg). Thus heap leaching alone can generate 50kg of CO2e per kg of gold. Precious metals and Rare Earth are among the most CO2 intensive materials in the world, although their total CO2 footprint is diminished by using them in small quantities.

80-90% energy and CO2 savings. If you are extracting copper from a 1% ore grade, heap leaching will require 225kWh/ton-Cu of energy, while a subsequent electro-winning step might require 500kWh/ton. By contrast, smelting might require 6,000 kWh/ton. This is the alchemy miracle of hydrometallurgical processing, and why we consider heap leaching to be an efficiency technology.

The energy economics of leaching operations depend on capex, opex, ore grades, recovery rates and chemicals costs. All of these variables can be stress-tested in our model, in the tabs overleaf and are backed up by data that has been aggregated from technical papers.