This data-file captures the costs of industrial cooling, especially liquid cooling using commercial HVAC equipment, across heat-exchangers, cooling tower evaporators and chillers. Our base case is that removing 100MW-th of heat has capex costs of $1,000/ton, equivalent to c$300/kW-th, expending 0.12 kWh-e of electricity per kWh-th, with a total cost of 7 c/ton-hour.

Across the US cooling market, the most common metric for measuring cooling capacity is in ‘tons’. This is shorthand for the coolness provided by 1 US ton of ice melting over the course of a day, equating to 3.52kW-th of heat removal. Providing 3.52 kW-th of cooling for one hour can thus also be called 1 ton-hour.

Cooling can be delivered via three mechanisms: simple heat exchange with ambient air or water (depends on ambient temperatures), evaporating some of the water in an evaporating tower (depends on water availability) and chilling a working fluid using a refrigeration cycle. In practice, all three may be used in combination (as exemplified in the chart below).

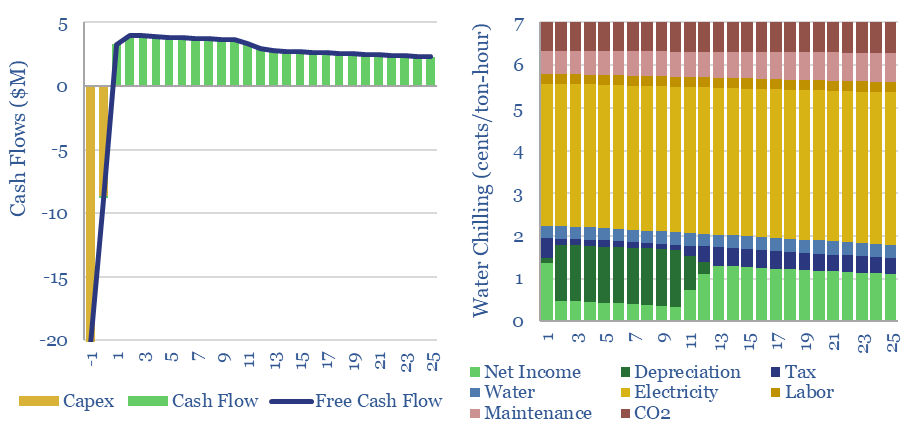

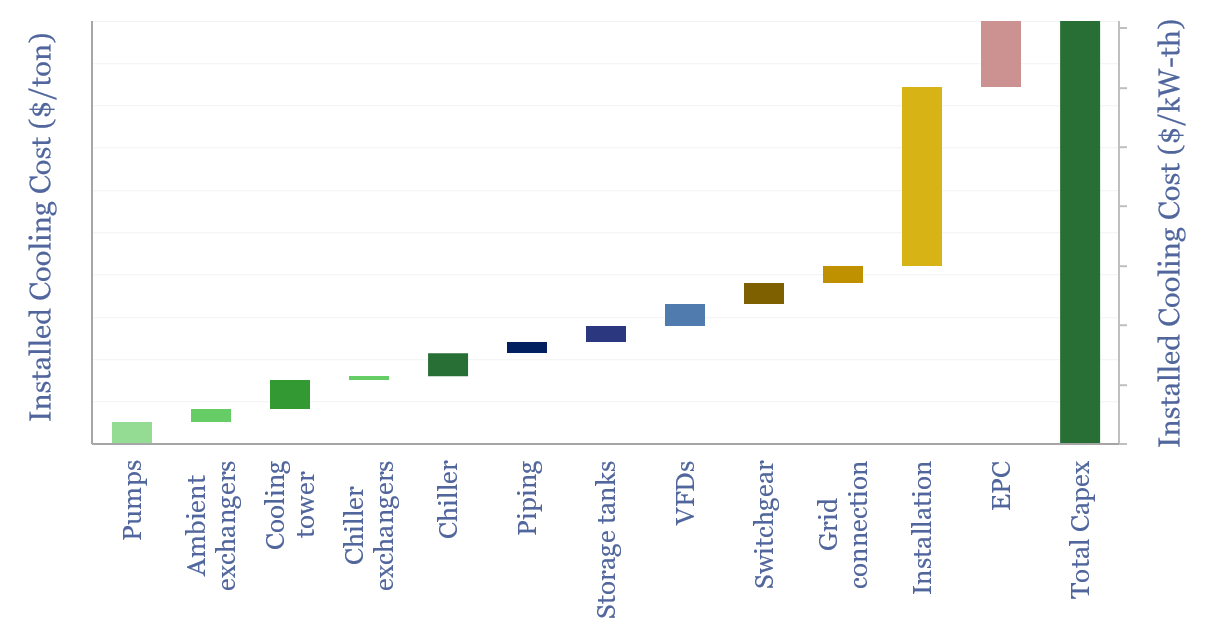

Capex costs of industrial cooling depend on the precise combination of equipment that is used, but a good ballpark is $1,000/ton, equivalent to $300/kW-th, based on our models of compressors, heat-exchangers, pumps, fans and blowers, storage tanks, piping, VFDs, switchgear, grid connections, engineering and construction.

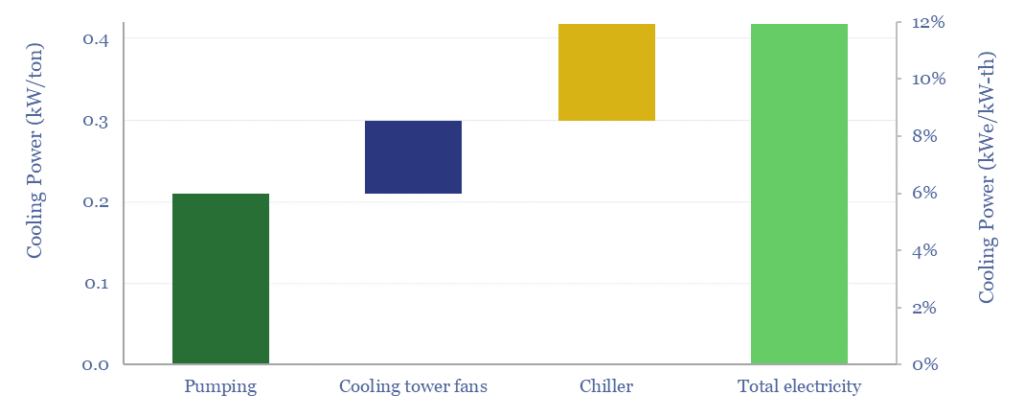

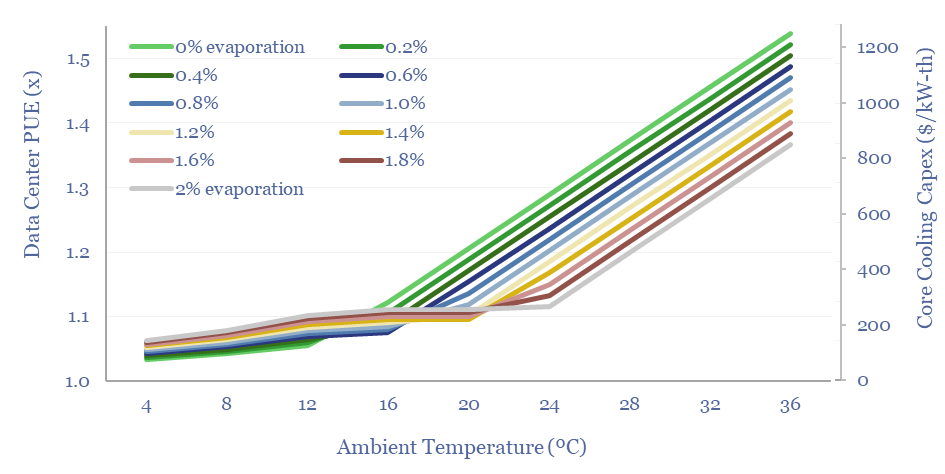

Removing each kWh-th of heat requires 0.12 kWh-e of electricity, in our base case, but the numbers vary as a function of water evaporation rates and ambient temperatures, running anywhere from 0.03 to 0.5 kWh-e per kWh-th. Cooling in water-scarce and hot climates is c60% more costly than in water-abundant and cool climates.

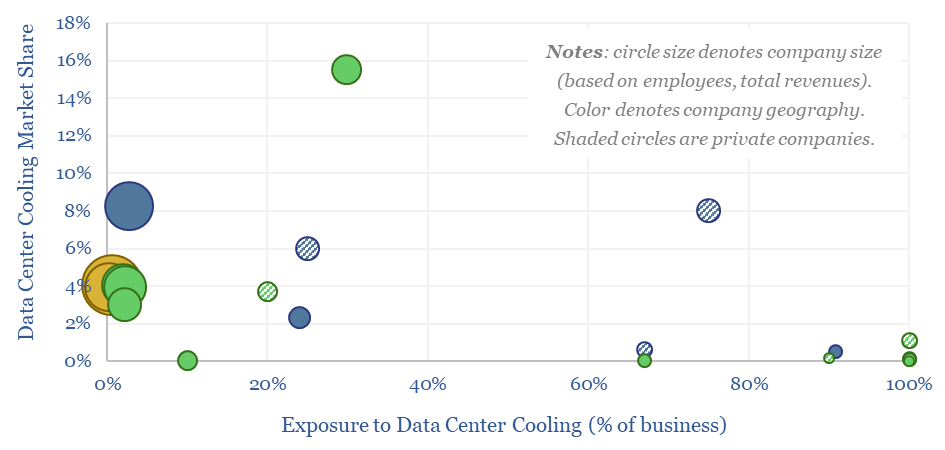

Base case numbers in our commercial cooling model are primarily geared to data-centers, where 10-20% of total installed costs will be on cooling, in order to keep chips below a thermal limit of 27ºC or cooler. Water intensity of AI computing can thus be estimated in the range of 1,000-3,000 liters per MWH, meaning that each ChatGPT query consumes as much as 10-30ml of water. Or alternatively, PUEs can be increased by c5-10% to avoid any water use in evaporators. Hence the data-file also screens 20 companies, with 65% of the market in data-center cooling.

All of our numbers into the costs of industrial cooling can be stress-tested in the data-file. Backup tabs of the model contain details of companies and our notes from technical papers.