50 companies make conductive silver pastes to form electrical contacts in solar modules. This data-file tabulates the compositions of silver pastes based on patents, averaging 85% silver, 4% glass frit and 11% organic chemicals. Ten companies stood out, including a Korean small-cap.

Producing over 500GW pa of solar modules per year from 2024 onwards, each containing 15 g/kW-DC of silver electrical contacts, implies total silver consumption of 7.5kTpa, which is over 20% of the global silver market. Hence this work follows on from our screen of silver miners to look at silver pastes for solar module manufacturing.

There are 50 companies producing the silver pastes that are screen-printed onto the front of solar modules, and increasingly also the back too (in TOPCon and HJT cells), forming the electrical contacts with the underlying silicon substrate. Can any companies have an edge?

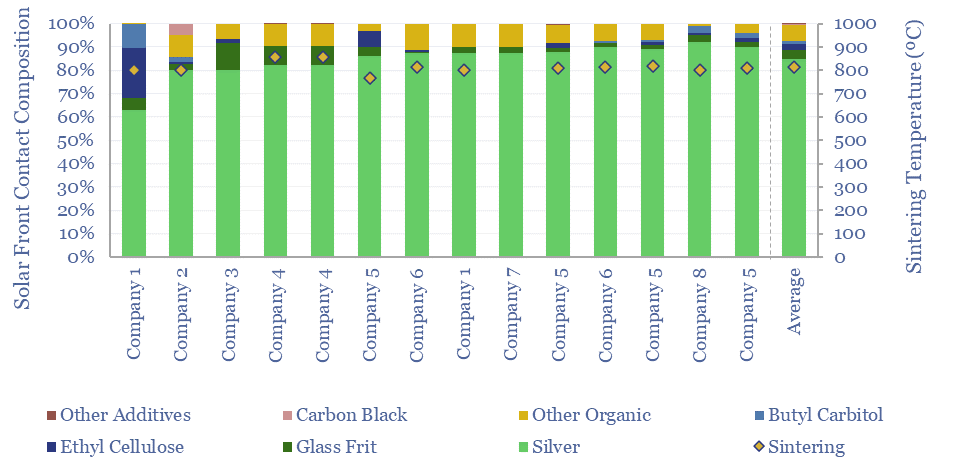

We reviewed 15 patents from 8 companies. Each has a subtly different formulation. But the average one is 85% silver, 4% glass frit, and 11% other organics. The silver particles average 1.3μm in diameter. These solid reagents are slurried in organic solvents, then screen-printed, then dried at 200-400ºC, then sintered at 800ºC.

The key objectives in the patents are to improve efficiency (often by 0.1-0.2% overall, e.g., by ensuring electrical contacts and minimizing resistance), improve printability, improve adhesion, and replace lead from the glass frit. Some of these improvements will enable silver thrifting, perhaps getting the per surface silver intensity down to 10 g/kW-DC in future, per our model here.

The role of the glass frit is to carry silver particles through the passivation layer and into contact with the underlying substrate during sintering. PbO and Bi2O3 are often used. Poorly designed frits cost over 10% in the efficiency of a solar module. Further details in the data-file.

Other additives optimize the viscosity and prevent foaming. Solvents often include ethyl cellulose or butyl carbitols. There are dozens of variations, noted in the data-file.

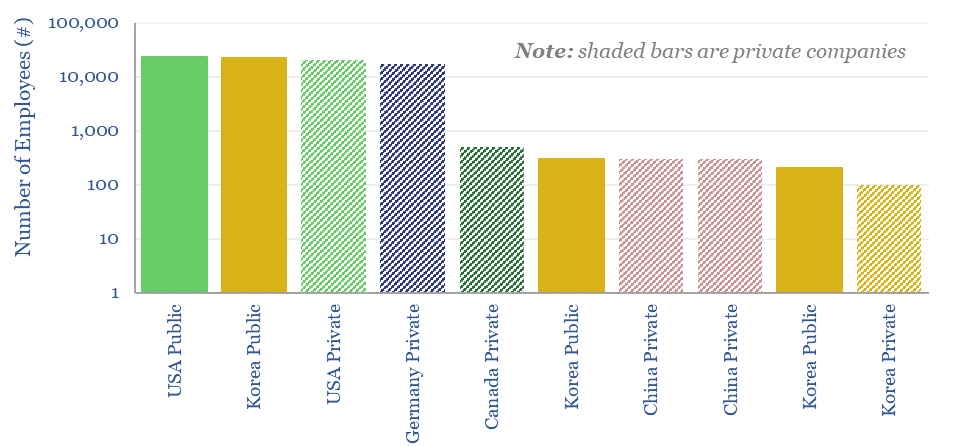

Ten companies in particular are profiled in the Companies tab, especially based in Korea, China, the US and Japan. A Korean small-cap company stood out from the patents as the most focused on silver pastes, optimizing silver particle sizes, glass frit compositions, micro-porosity and low resistance after sintering. But the space is also highly competitive.