This data-file captures the economics of sulphur recovery from H2S via the Claus process, which is an important industrial process cleaning up sour gases from the oil and gas industry, but also in the production of sulphuric acid for phosphate fertilizer and metals/materials production.

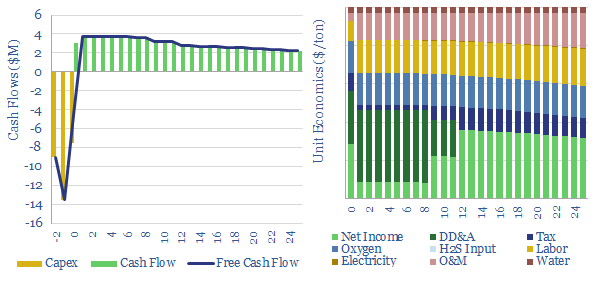

Cash costs are likely to be in the range of $40-60/ton. While we think a marginal price of $100/ton should incentivize new Claus units with a 10% IRR. This is assuming H2S inputs are effectively free, as sourced from hydroprocessing or gas sweetening.

Producing sulphur is not energy or CO2 intensive, at 0.1 tons CO2/ton of sulphur. The majority of this is inherited from oxygen enrichment, which improves yields, but in turn requires cryogenic air separation.

If the world’s sulphur and H2SO4 mostly come from 1,000 refineries and oil processing facilities, this might raise a question in the energy transition about coping with future sulphur shortages?

Recent Commentary: please see our article here for why sulphur recovery unit economics are increasingly important for supply chains in the energy transition, especially for lithium and fertilizer production.