Crude to chemicals: there will be naphtha?

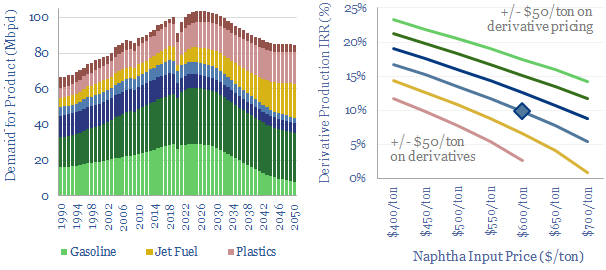

…combustion properties and ‘low knocking’. So BTXs could face a supply glut. Key numbers are explained on page 6. Which petrochemical processes use BTX? We have identified four key petrochemical…

…combustion properties and ‘low knocking’. So BTXs could face a supply glut. Key numbers are explained on page 6. Which petrochemical processes use BTX? We have identified four key petrochemical…

…that span naphtha-reforming, BTX separation into paraxylene, oxidation to PTA, plus ethane cracking, ethylene oxide and ethylene glycol. This data file covers the polyester production process, step by step, including…

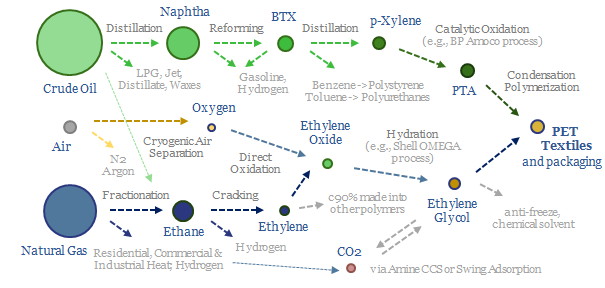

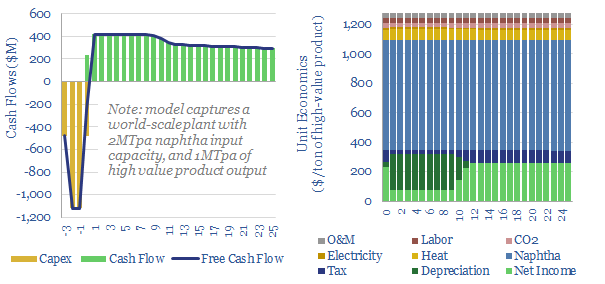

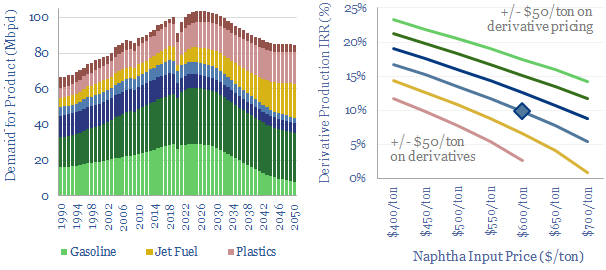

Naphtha cracking costs $1,300/ton for high value products, such as ethylene, propylene, butadiene and BTX aromatics, in order to derive a 10% IRR constructing a new, greenfield naphtha cracker, with…

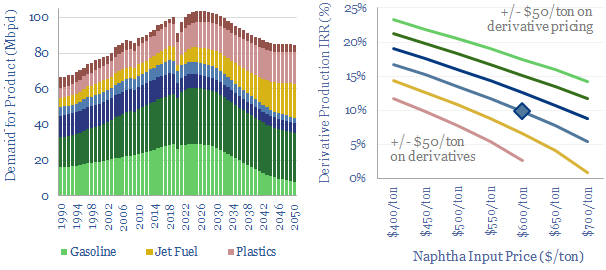

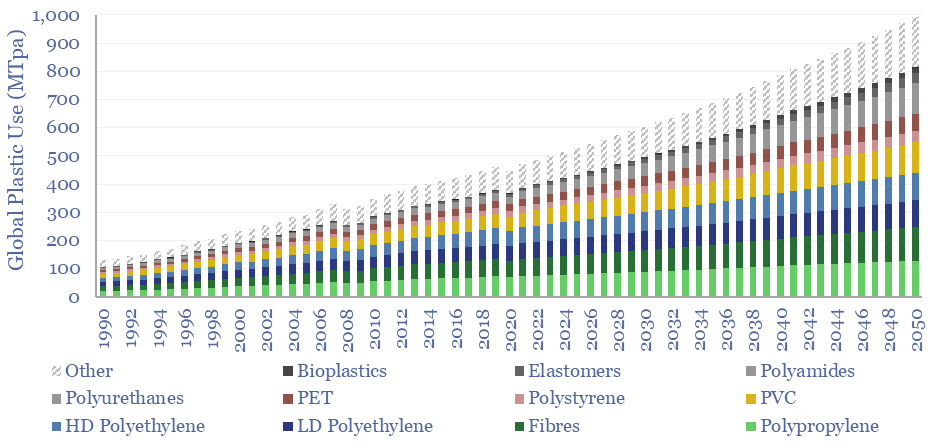

…a defining theme in the energy transition, as many polymers draw inputs from the catalytic reforming of naphtha. Today, 70% of BTX reformate is blended into gasoline, but we see…

…So it is often said oil refiners should ‘become chemicals companies’. It depends. This 18-page report charts petrochemical pathways and sees greater opportunity in chemicals that can absorb surplus BTX….

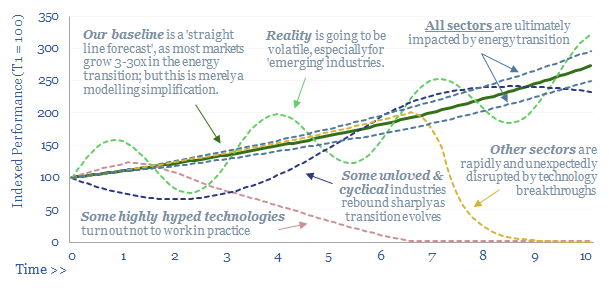

…unexpectedly double the margins of polyurethane and textile fiber producers, which can source increasingly cheap BTX feedstocks as demand for gasoline declines (note below). Across all of our work, our…