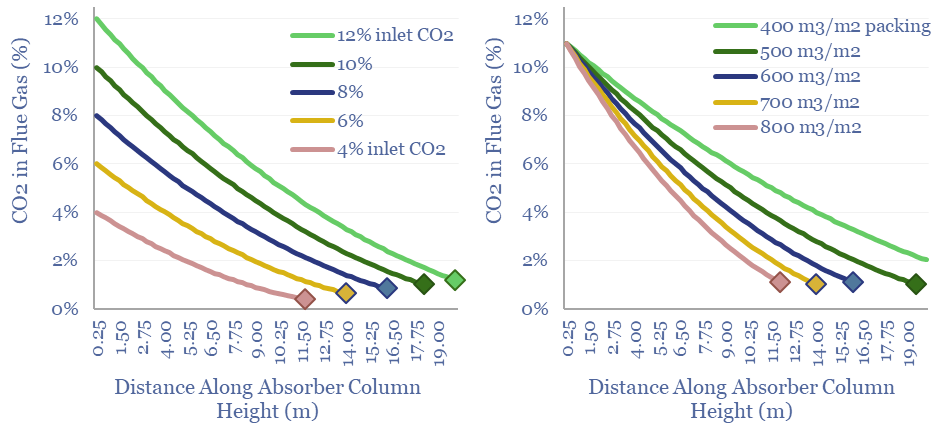

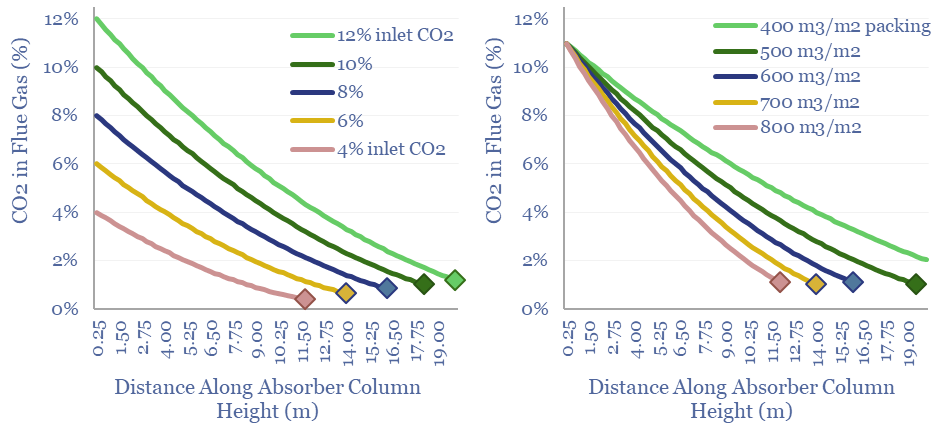

Post-combustion CCS plants flow CO2 into an absorber unit, where it will react with a solvent, usually a cocktail of amines. This data-file quantifies operating parameters for CCS absorbers, such…

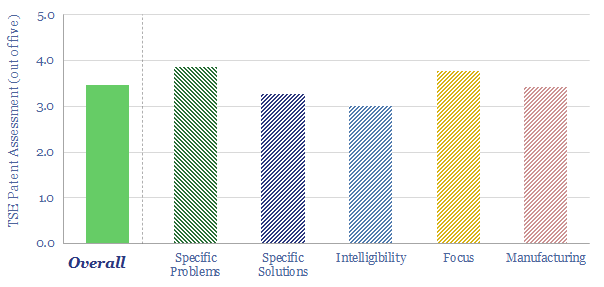

…below 10%. This is better than the best amines. Hence our 15-page note lays out ten key questions, to help decision makers de-risk next-generation CCS membranes. The technology is early-stage….

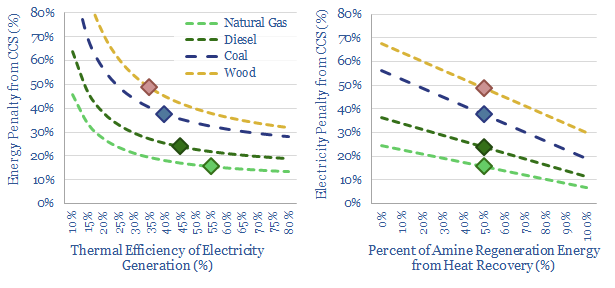

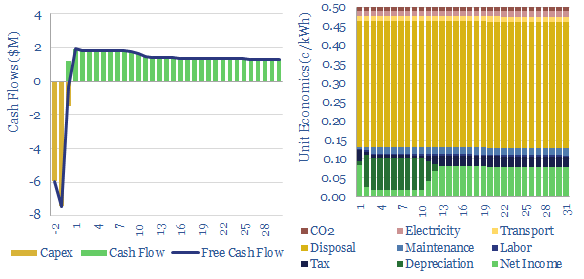

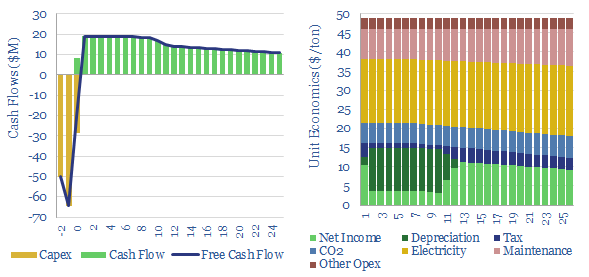

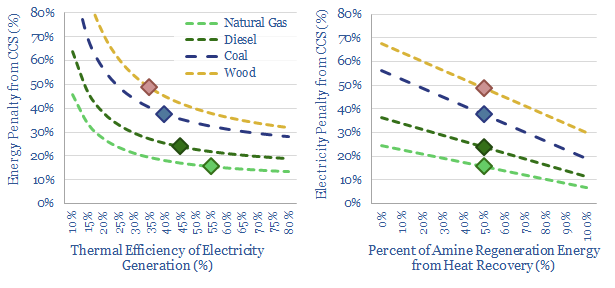

…CCS. They include direct electricity use (e.g., for CO2 compression in pipelines and disposal facilities). And they include thermal loads in the amine reboiler, absorbing heat that could otherwise have…

…to separate CO2 (4-40% concentration) from air (mostly nitrogen). Amines can do this, but the process is costly, energy intensive and amines can be degraded by contaminants. Oxy-combustion is an…

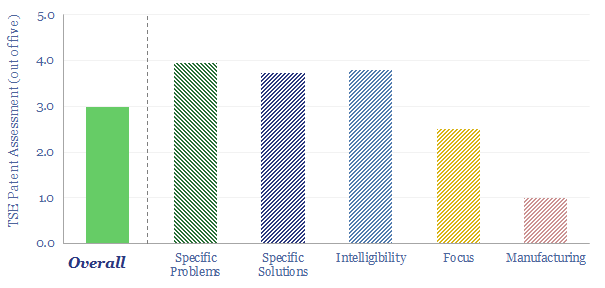

Advantage Energy is a Montney gas and oil producer, which recently sourced a $300M investment from Brookfield to scale up its Entropy23 amine blend for natural-gas CCS. Entropy CCS technology…

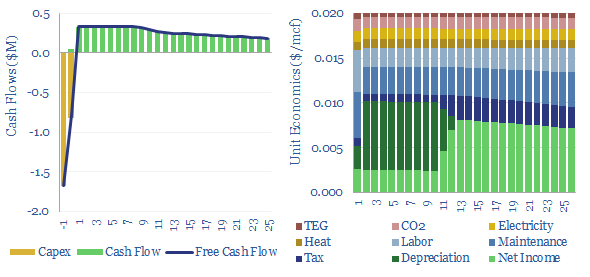

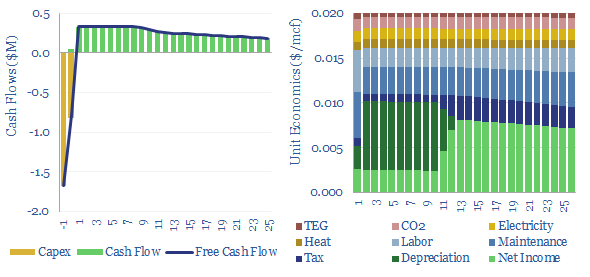

…same plant configuration as for post-combustion CCS using amines. The global TEG market is worth around $800M per year, implying c500kTpa of production at $1.5-2.0/kg. TEG is made via the…

…important in the energy transition, as exhaust gases require large amounts of clean-up upstream of post-combustion CCS plants, to prevent releases of amines or their breakdown products, which can be…

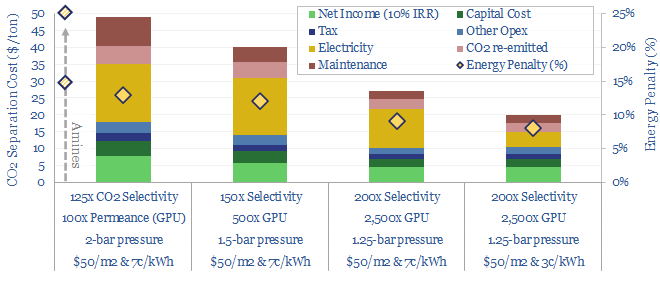

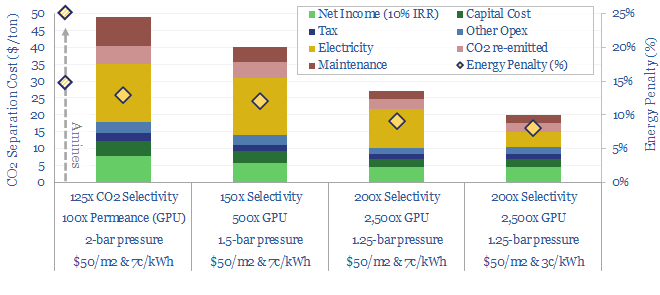

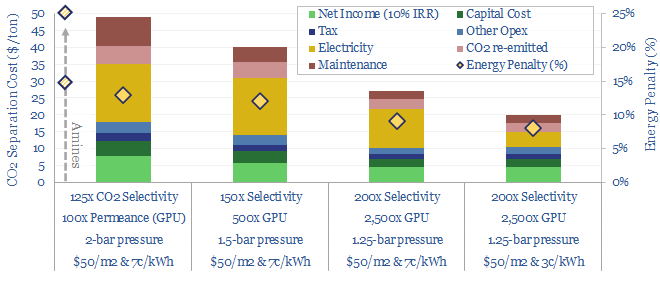

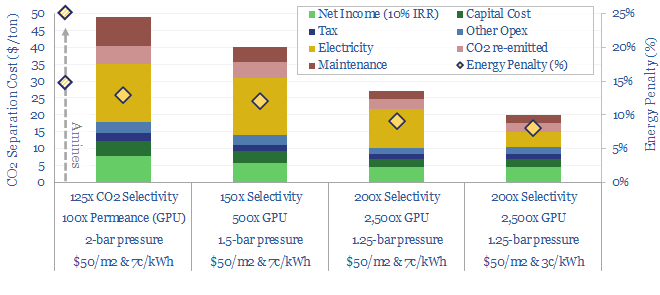

…cost of $20/ton and an energy penalty below 10%. This is better than the best amines. We recently explored this opportunity in a detailed research note, which posed ten criteria for…

…which greatly exceeds the best amines. This 15-page note lays out ten key questions, to help decision makers de-risk next-generation CCS membranes. The technology is early-stage. Companies are also noted….

…in this model. Membrane stability is also important, as our recent research has highlighted how amines and other CO2-reactive compounds can degrade, especially in the presence of impurities. The data-file…