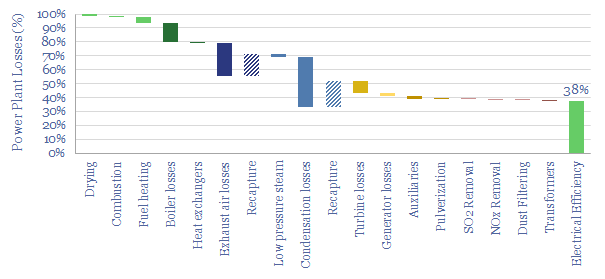

…this is after unavoidably heavy energy penalties and requires extensive gas clean-up to avoid combustion contaminants from degrading amines. Data are also aggregated on the generation and efficiency of c340…

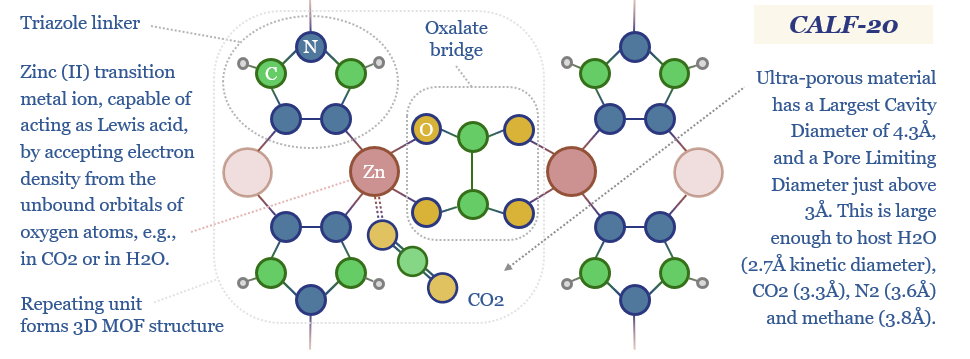

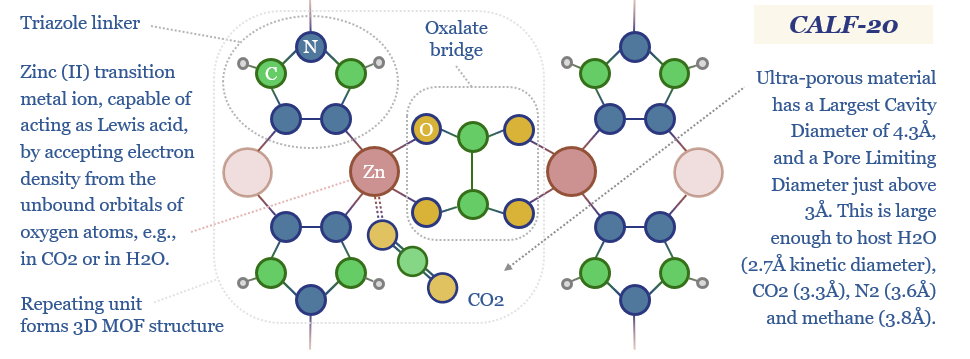

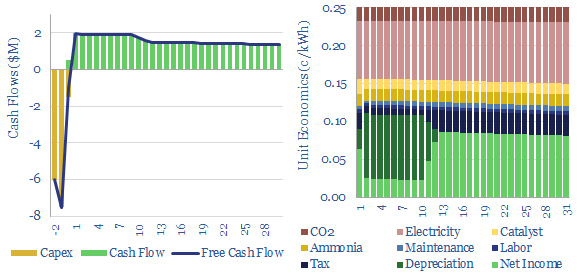

…on pages 10-12. What costs for MOFs in CCS? We can de-risk 50% lower CCS costs using MOFs rather than amines, when we take the numbers back to first principles,…

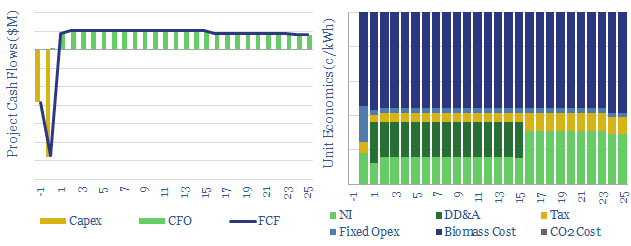

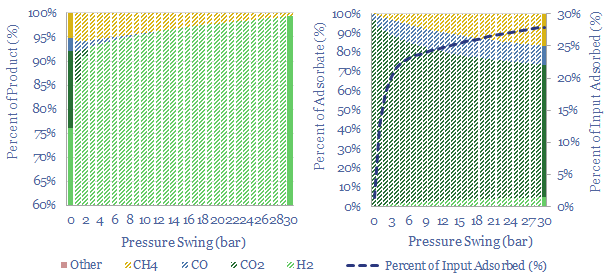

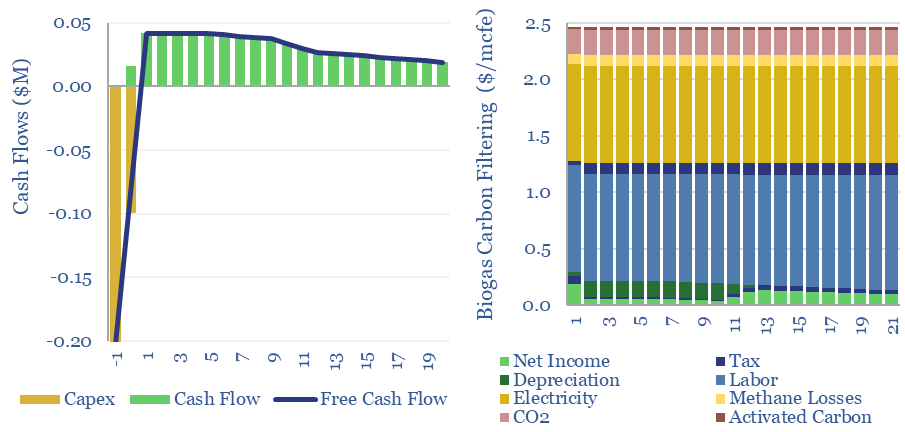

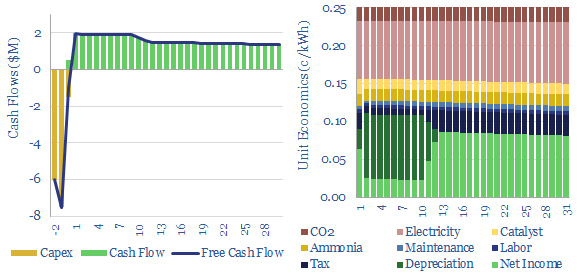

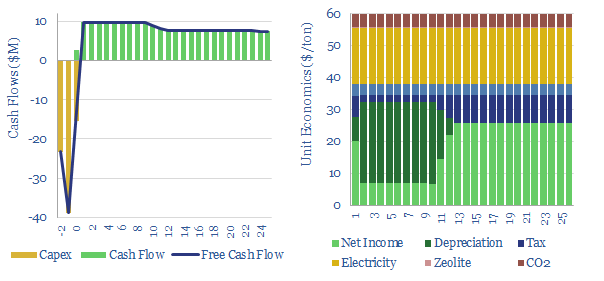

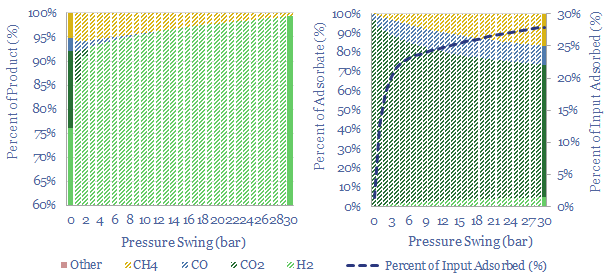

…of gas compression. Please download the data-file to stress-test your own economic assumptions, and for the breakdown of pressure swing adsorption costs. Other techniques for gas separations include amine separations,…

…(page 16). Pressure swing adsorption is an important tool for industrial separations, alongside amine separations, membrane separations and cryogenic separations, as covered in our broader research. For access to all…

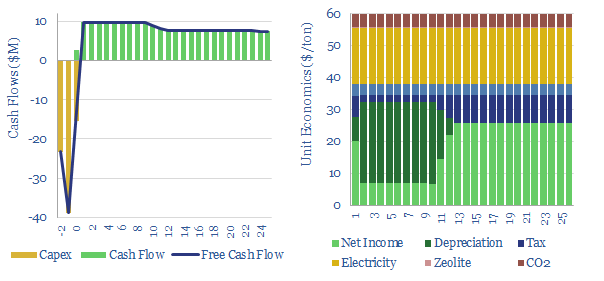

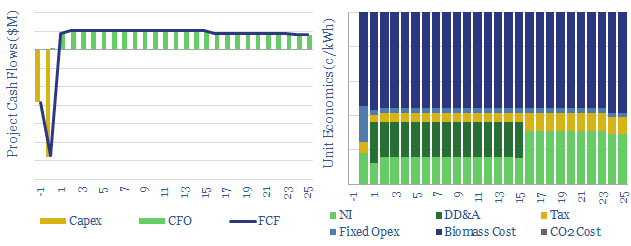

…simple (compared to other CCS opportunities with high energy penalties and amine degradation issues), and can earn 20% IRRs when we model the costs and a share of 45Q revenues…

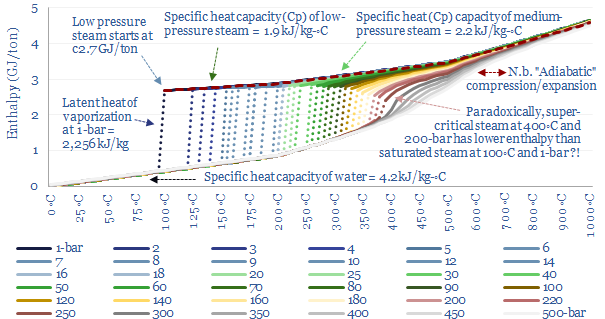

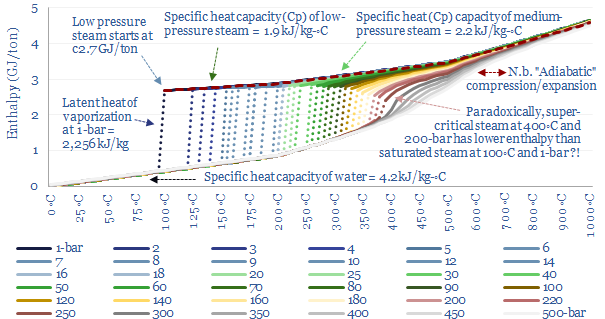

…cart Steam is used across dozens of industrial processes that have crossed our screens, from manufacturing, to steam cracking, to hydrogen reforming, to amine regeneration in CCS to nuclear power….

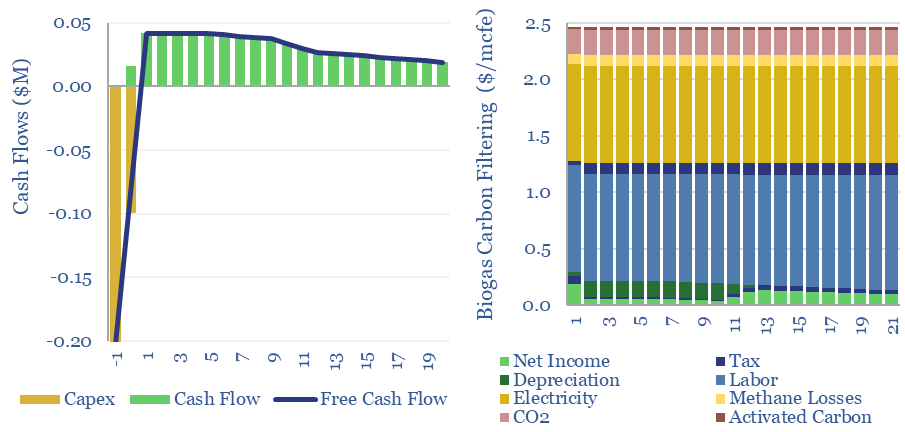

…results from stress-testing our other models, including for pressure swing adsorption, amine plants, membrane separations, cryogenic gas separations, gas dehydration, compressors and small-scale pipelines. Total costs of upgrading biogas into…

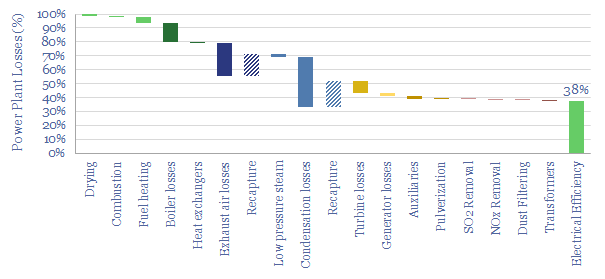

…are only around 10-20%, versus 40% for CCS at power plants combusting solid fuels. For simple cycle gas turbines, the amine reboiler duty can often be met entirely via waste…

…combustion facility with CCS, it may be necessary to strip out the SOx then the NOx upstream of the amine unit, to avoid the formation of highly toxic nitrosamines (note…

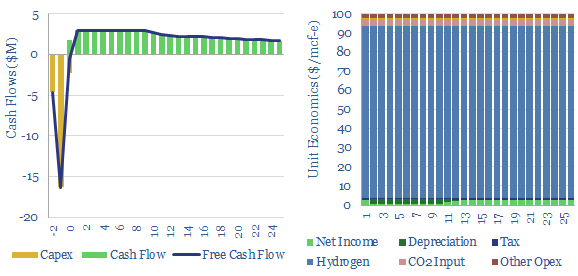

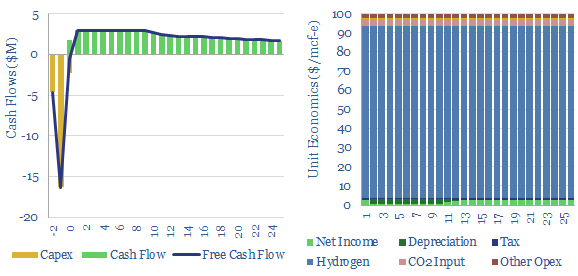

…other green hydrogen electrolyser economics. Another $3/mcf of the cost is from sourcing CO2 from an amine plant, or you could source the CO2 from direct air capture. Total energy…