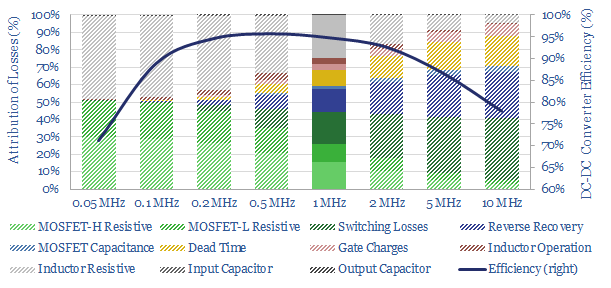

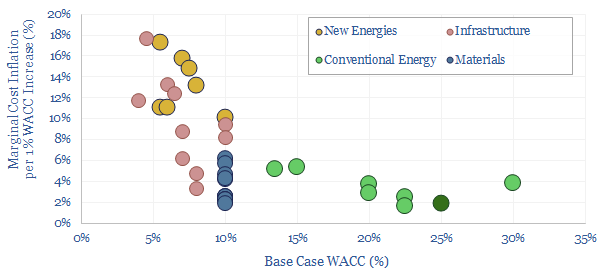

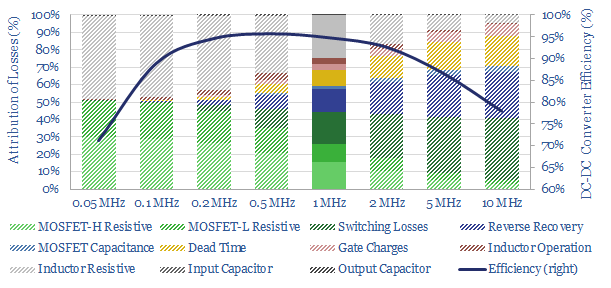

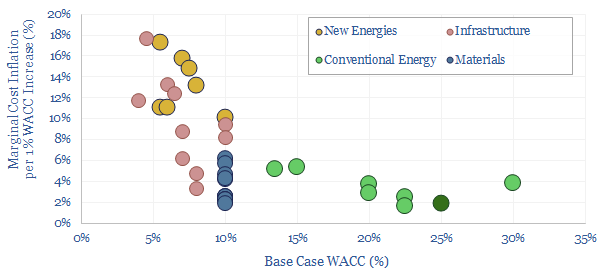

…different input variables. We think value will accrue to leading semiconductor and power-electronics companies, that can improve the efficiency of electrification technologies. Recent examples include Silicon Carbide (SiC) semiconductor, Zero-Voltage…

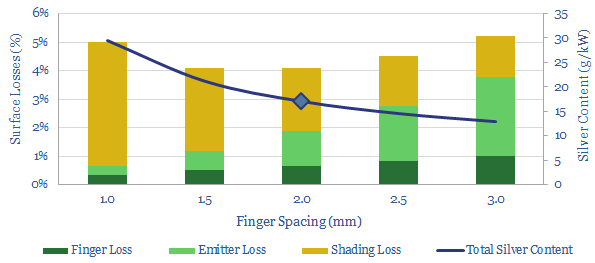

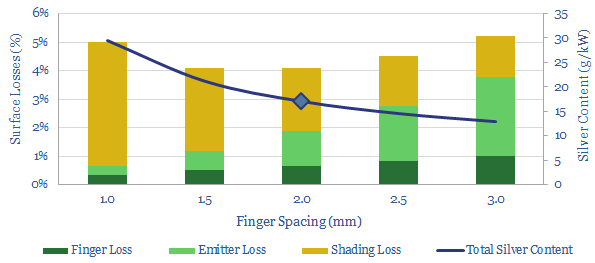

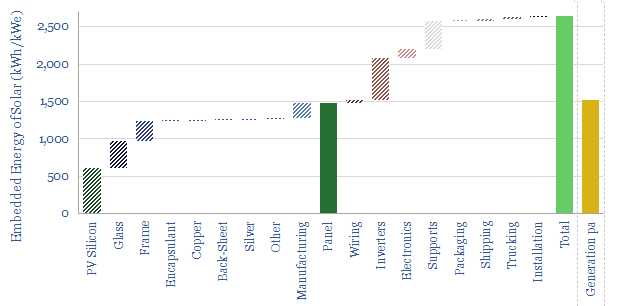

…contact fingers (0.5-1%), resistance in the emitter (1.5-2.5%) and resistance due to shading of the silicon by fingers and busbars (2-3%). This data-file allows stress-testing of different impacts on solar…

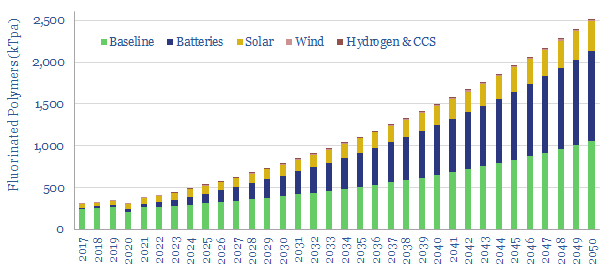

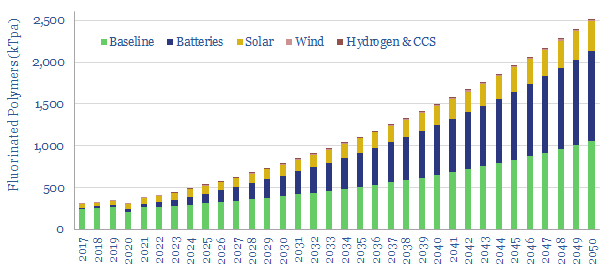

…the most resilient polymers in the world (page 2). Yet they are overlooked. When you think about the materials in solar panels, you are primarily going to think about silicon,…

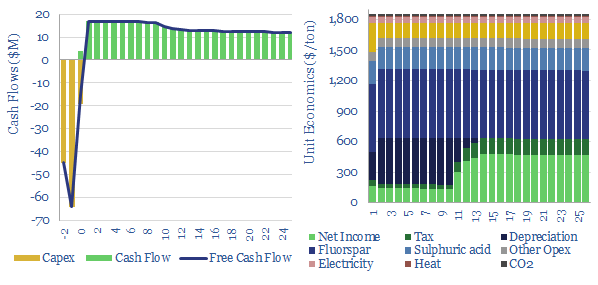

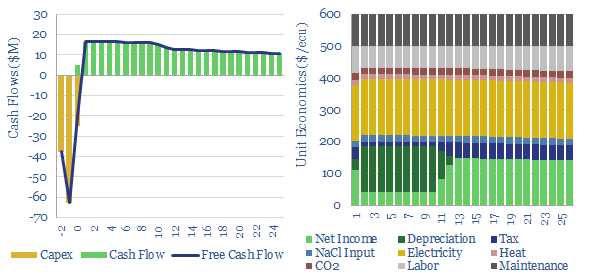

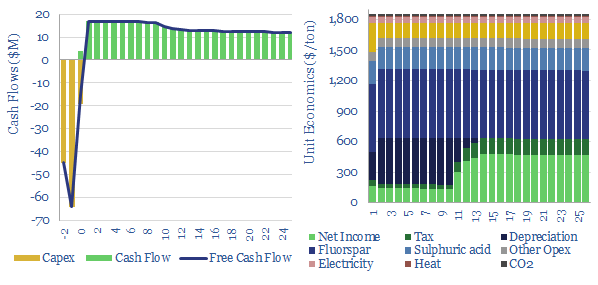

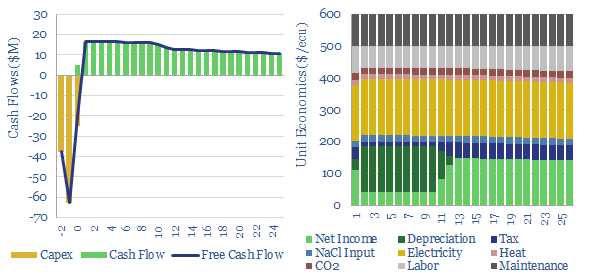

…in its own right, to etch silicon chips, metals and blow insulation foams. This economic model captures the production of hydrogen fluoride from acid-grade fluorspar and sulfuric acid. We think…

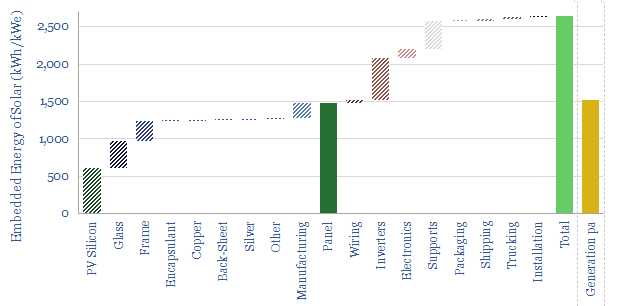

…solar panel is about 65% glass, 15% aluminium, c10% polymers (mainly EVA encapsulants and PVF back-sheet), c3% copper. Photovoltaic silicon is only 5% of the panel by mass, but about…

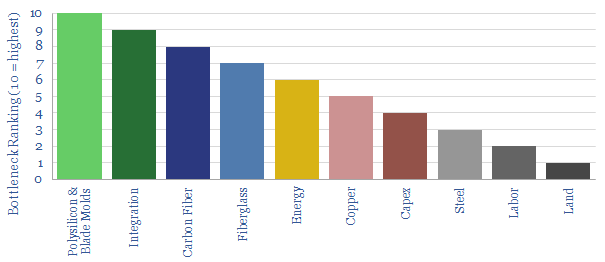

…more materials becomes harder. Unfortunately solar panels do not grow on trees. Building more solar requires building more PV silicon, or silver, or copper production facilities. These are also capital…

…to the Siemens Process, used to make 92% of the world’s PV silicon in 2021. Energy intensity is middling. Electricity comprises 30% of the total marginal cost, and c45% of…

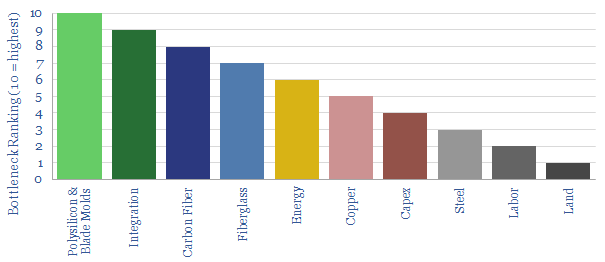

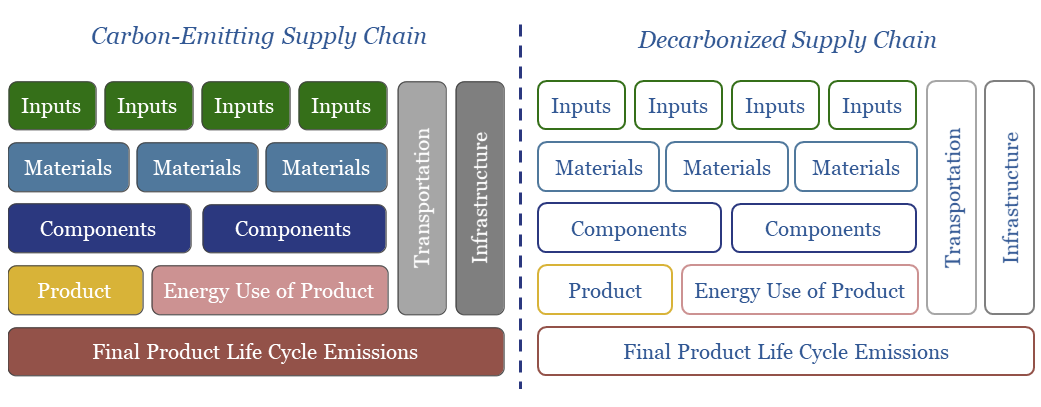

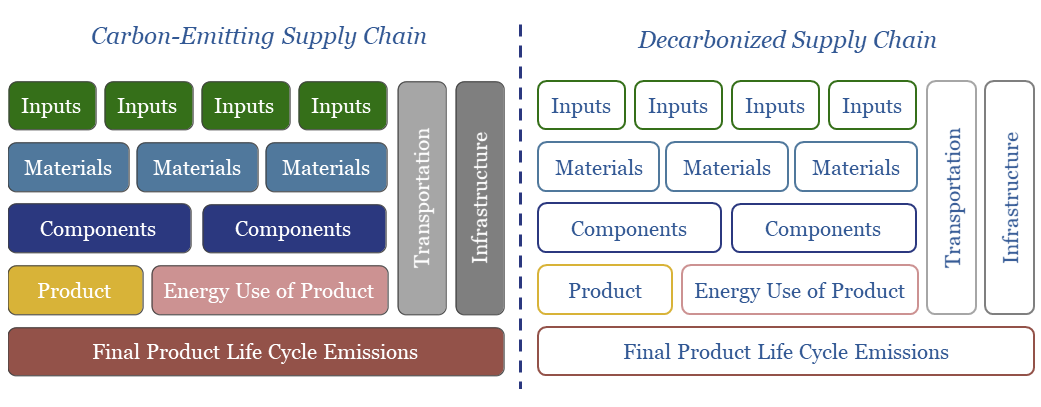

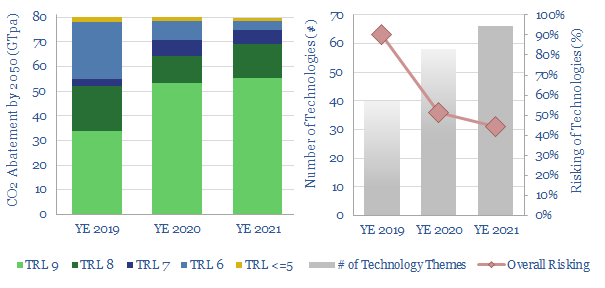

…our assessment (page 3). Materials are more challenging, and we map out the total demand pull on global steel, copper, silicon, fiberglass and carbon fiber; and we also discuss the…

…turbine blades and hydrogen storage tanks), photovoltaic silicon (used in solar panels), lithium (used in batteries), neodymium magnets (used in wind turbines and EVs), dielectric gases (used in electricity distribution)…

…first electric wind turbine was built in Scotland in 1887 and the first PV silicon was produced at Bell Laboratories in 1954. Today wind and solar comprise 9% of global…