Polymers and higher olefins: the economics?

…ton of product, and can be c80-90% lower than the prior step of ethane cracking. However conditions can vary vastly, from 50-300C and 50-25,000 psi, for different polymers and processes….

…ton of product, and can be c80-90% lower than the prior step of ethane cracking. However conditions can vary vastly, from 50-300C and 50-25,000 psi, for different polymers and processes….

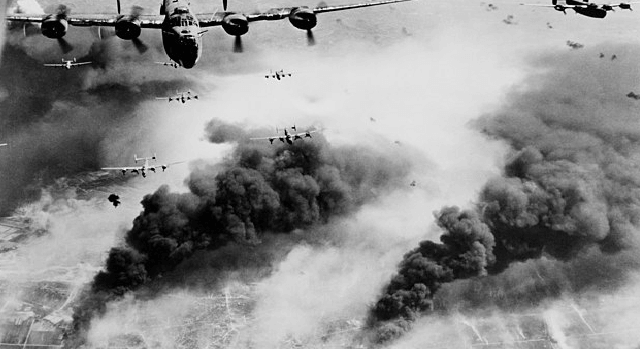

…was produced using catalytic cracking technology, pioneered in the 1930s, and deployed in vast, 15-story refinery units, at complex US refineries. The US ramped its production of 100-octane gasoline from…

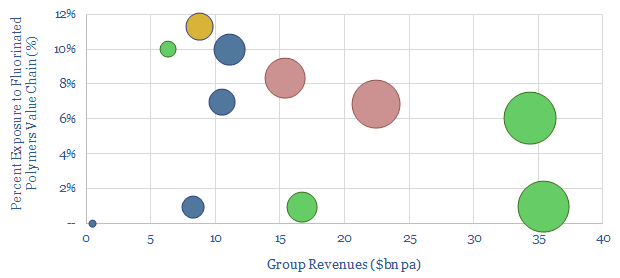

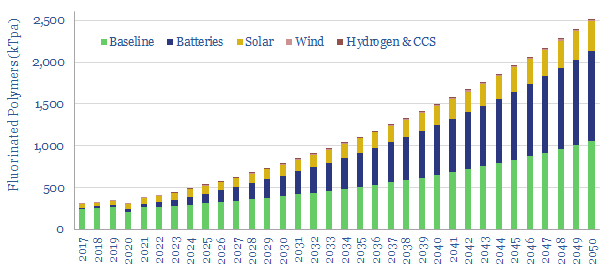

…data from DuPont, suggesting that over 16% of solar panels deployed in the field have now suffered cracking in their back-sheets. This is an argument for using high-grade fluorinated polymers….

…upside. Can fluorinated polymers be substituted? We answer this question on page 7, including interesting data on the cracking of solar panel back-sheets. So how are fluorinated polymers produced? The…

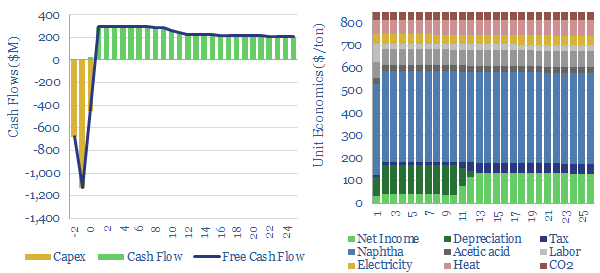

…process heat for the cracking/reforming of naphtha. Energy costs are a major contributor to PX production costs, but less significant for oxidizing PX into PTA. How does the cost of…

…We think the dominant process in the West is partial oxidation of methane, at very hot temperatures, around 2,000-3,000◦C. Another method purifies acetylene by-products from ethane cracking. A third pathway…

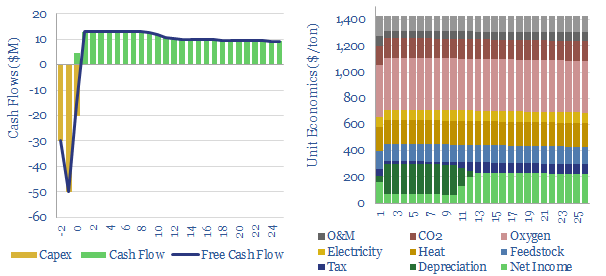

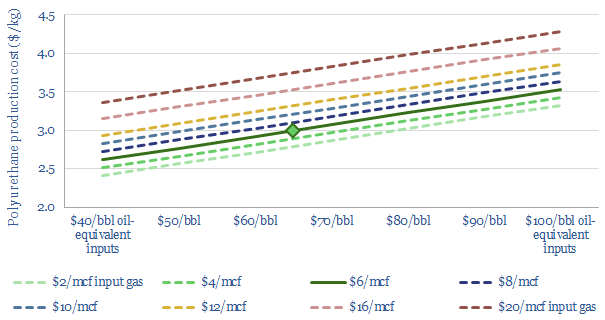

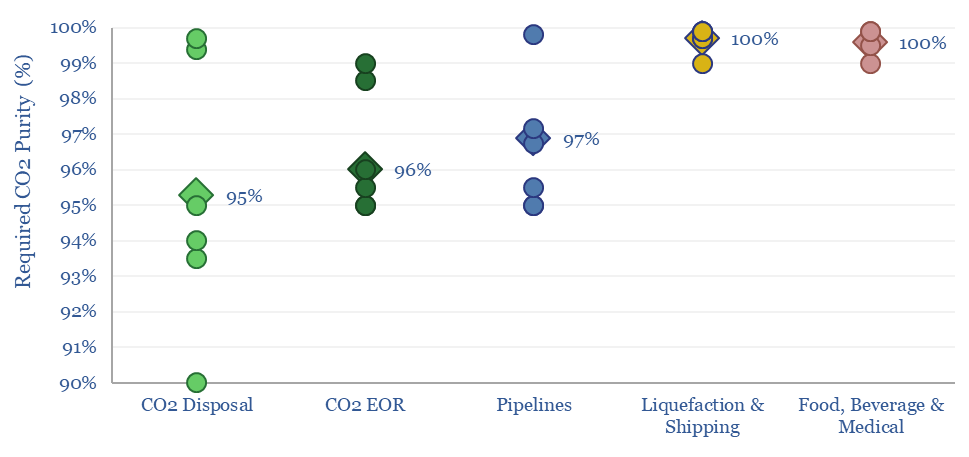

…chains, naphtha cracking, air separation, hydrogen production, chemical separations, CO2 separation, ammonia synthesis, nitric acid, methanol, formaldehyde, chlor-alkali, acetylene et al. Can you use green hydrogen to decarbonize polyurethane? Substituting…

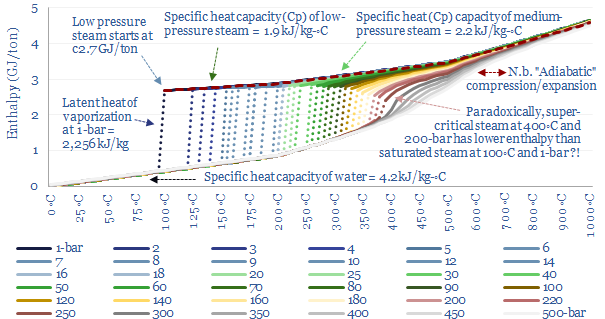

…cart Steam is used across dozens of industrial processes that have crossed our screens, from manufacturing, to steam cracking, to hydrogen reforming, to amine regeneration in CCS to nuclear power….

…Fe[2+] (aq) + H2 (g). It is never good to dissolve your pipeline from the inside out. Furthermore, the H2 can cause further stress cracking. Hence water is usually limited…

…production, which starts via naphtha cracking. We have also assessed the economics of Eastman’s methanolysis technology, which dissolves polyesters in ethylene glycol and dimethyl terephthalate, then uses 200ºC methanol at…