Search results for: “oxygen”

-

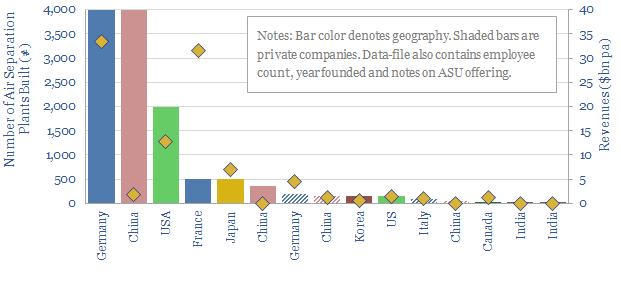

Cryogenic air separation: company screen?

Over $100bn pa of industrial gases and $5-6bn pa of cryogenic air separation plants are produced each year. This data-file is a screen of leading industrial gas companies and cryogenic air separation companies, breaking down their market share (number of ASUs constructed) history, geography, sales and headcounts.

-

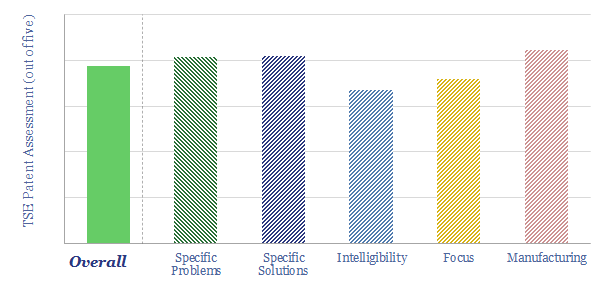

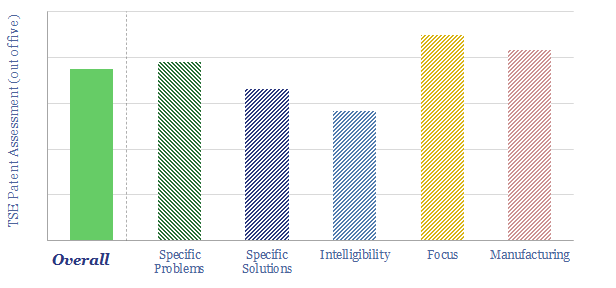

Membrane Technology and Research: CCS breakthrough?

Membrane Technology and Research Inc. (MTR) is a private company, specializing in membrane separations, for the energy industry, chemicals and increasingly, CCS. Its Gen 2-3 Polaris membranes have 50x CO2:N2 selectivity, 2,000-3,000 GPU permeabilities, and are at TRL 6-7. Is there a moat?

-

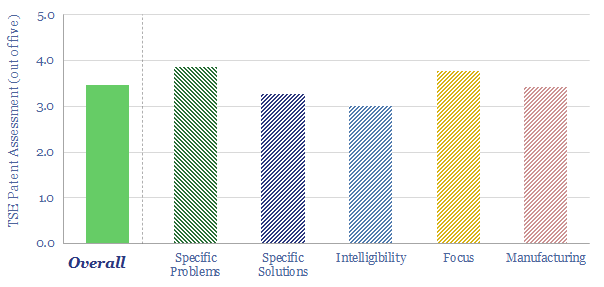

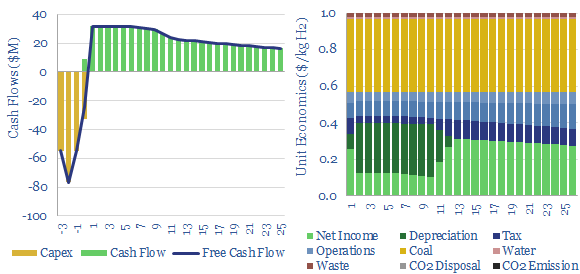

NET Power: gas-fired power with inherent CO2 capture?

Our NET Power technology review shows over ten years of progress, refining the design of efficient power generation cycles using CO2 as the working fluid. The patents show a moat around several aspects of the technology. And six challenges at varying stages of de-risking.

-

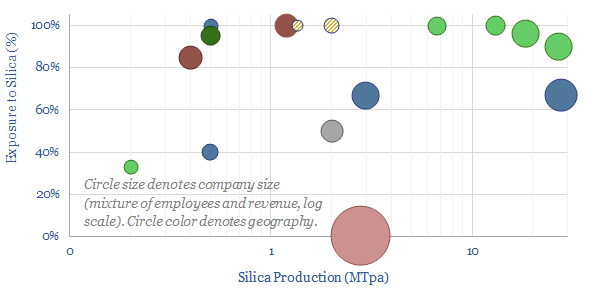

Silica producers: screen of leading companies?

Highly pure silica sand, with well over 95% SiO2 content and less than 0.6% iron oxide, is an important resource used in making glass, metal foundries, “proppant” for hydraulic fracturing in the oil and gas industry and making high-grade silicon (for chips and PV silicon). The market is 350MTpa. This data-file is a screen of…

-

Costs of hydrogen from coal gasification?

What are the costs of hydrogen from coal gasification? This model looks line-by-line, across different plant configurations, aggregating data from technical papers. Black hydrogen costs $1-2/kg. But CO2 intensity is very high, as much as 25 tons/ton. It can possibly be decarbonized resulting in semi-clean hydrogen costing c$2.5/kg.

-

Nexwafe: PV silicon breakthrough?

Nexwafe is growing standalone silicon wafers on mono-crystalline seed wafers, with no need to slice ingots. It should improve solar efficiency, materials intensity and CO2 intensity. Our technology review found 60 patent filings and can partly de-risk growth ambitions.

-

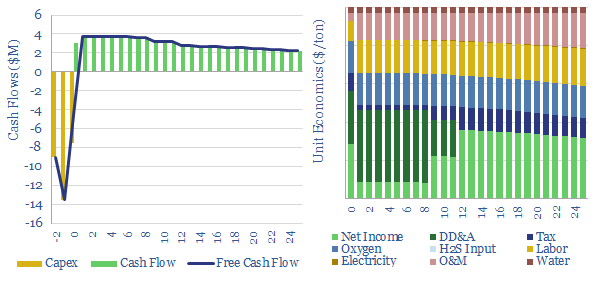

Sulphur recovery units: Claus process economics?

This data-file captures the economics of producing sulphur from H2S via the Claus process, yielding an important input for phosphate fertilizers and metals. Cash costs are $40-60/ton and marginal costs are $100/ton. CO2 intensity is low at 0.1 tons/ton. Data-file explores shortages in energy transition?

Content by Category

- Batteries (85)

- Biofuels (42)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (87)

- Data Models (801)

- Decarbonization (156)

- Demand (106)

- Digital (51)

- Downstream (44)

- Economic Model (196)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (266)

- LNG (48)

- Materials (79)

- Metals (70)

- Midstream (43)

- Natural Gas (144)

- Nature (75)

- Nuclear (22)

- Oil (161)

- Patents (38)

- Plastics (44)

- Power Grids (118)

- Renewables (148)

- Screen (109)

- Semiconductors (30)

- Shale (50)

- Solar (67)

- Supply-Demand (45)

- Vehicles (90)

- Wind (41)

- Written Research (339)